Impact fatigue performance evaluation test machine for presser foot material of sewing machine

A technique for evaluating test and impact fatigue, applied in the field of sewing machinery manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

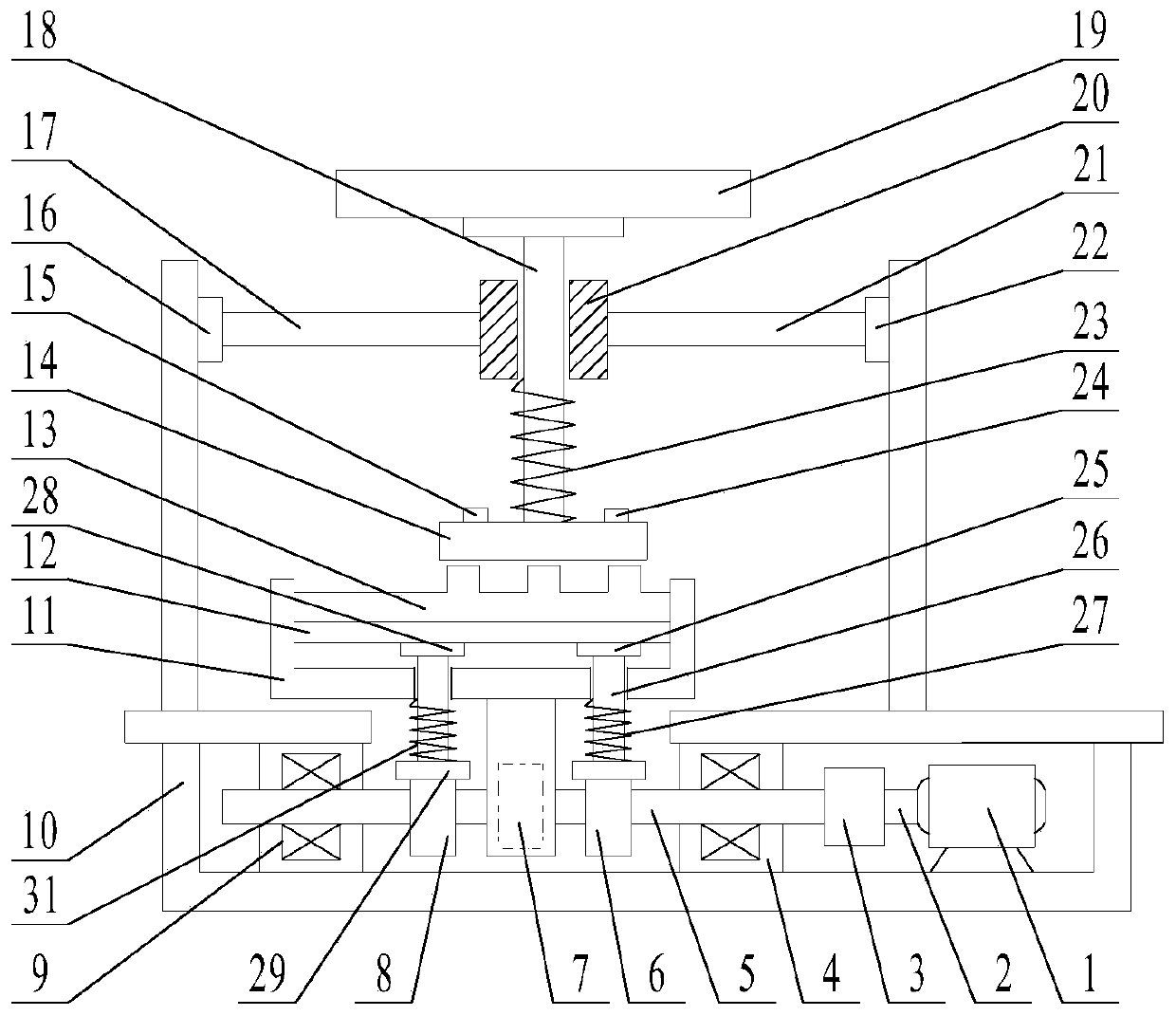

[0013] figure 1 It is a structural schematic diagram of a testing machine for evaluating the impact fatigue performance of sewing machine presser foot materials disclosed in the present invention. The testing machine can detect Damage to the coating on the surface of the sewing machine presser foot material.

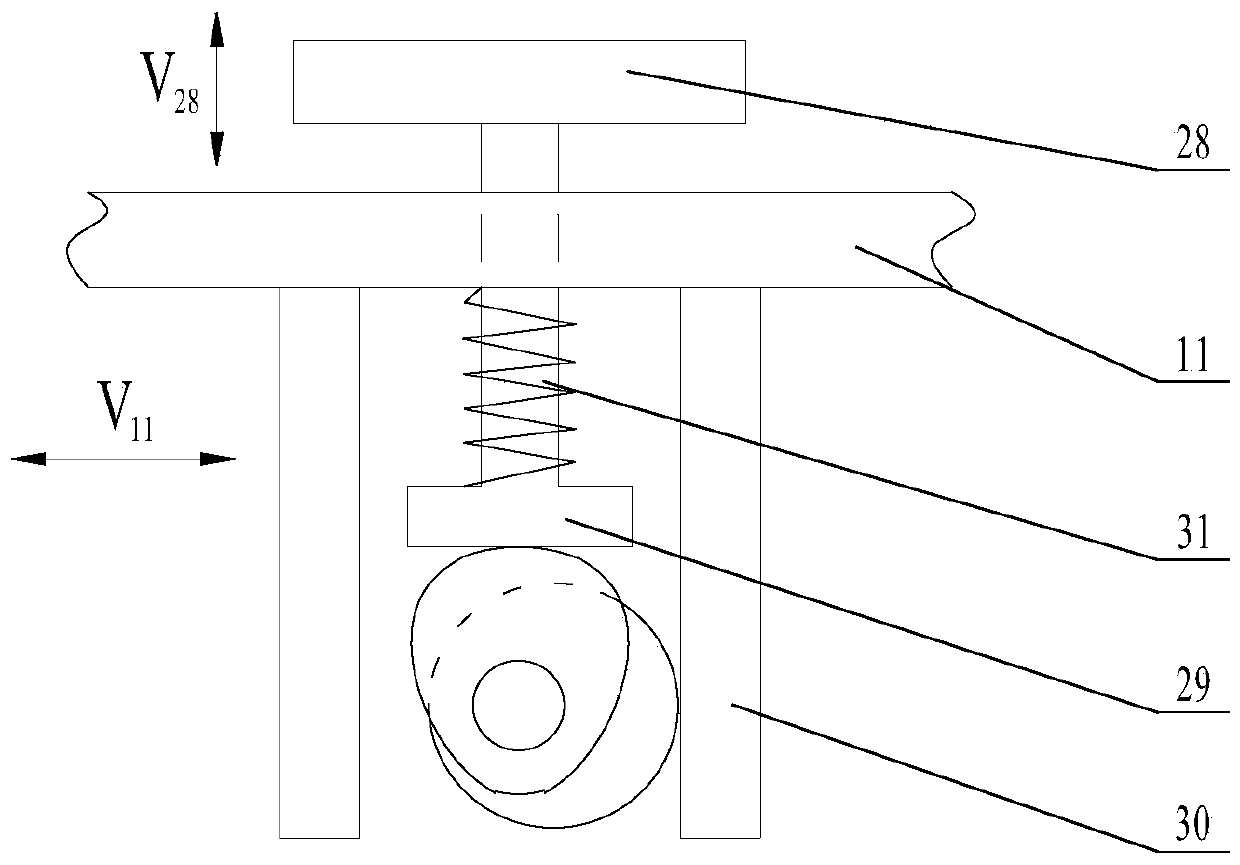

[0014] The presser foot material loading system includes a presser foot material 14, a beam I17, a pressing rod I18, a pressure block I19, a guide sleeve 20, a beam II21 and a spring I23. The pressure block I19 is fixedly connected with the pressure rod I18 through the thread pair, the pressure rod I18 moves in the guide sleeve 20, the spring I23 is installed on the pressure rod I18, and is located between the guide sleeve 20 and the presser foot material 14, the presser foot material 14 It is fixedly connected with the pressure rod I18 through the thread pair.

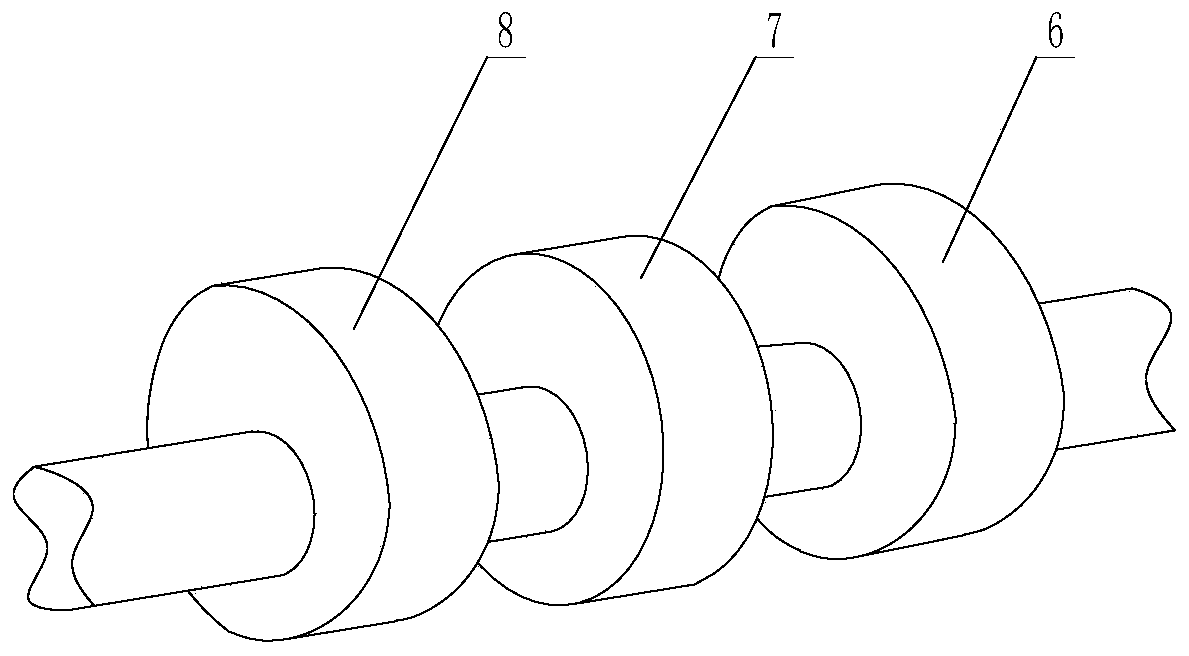

[0015] The feed dog transmission system includes motor 1, motor shaft 2, coupling 3, bearing housing Ⅰ4, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com