Hybrid integrated circuit tube shell and method for preventing glass insulator from breaking

A technology of hybrid integrated circuits and glass insulators, applied in circuits, insulators, electrical components, etc., can solve problems such as sealing failure, glass insulator cracks, product scrapping, etc., and achieve the effect of reducing stress and preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

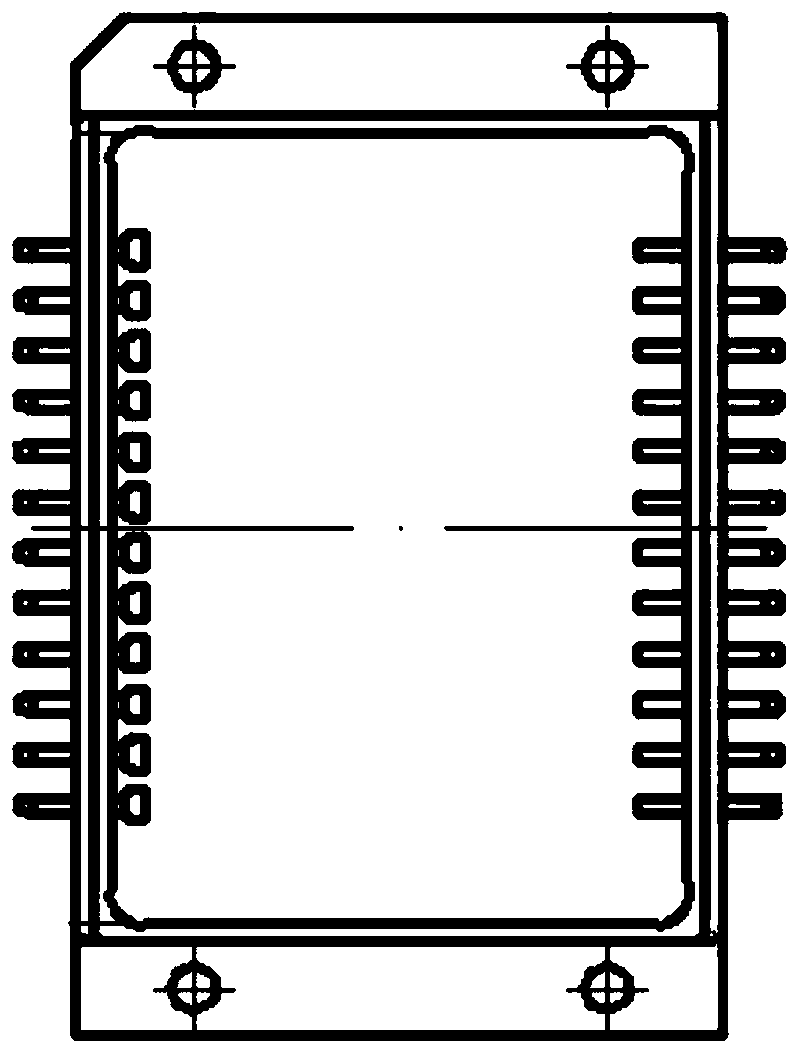

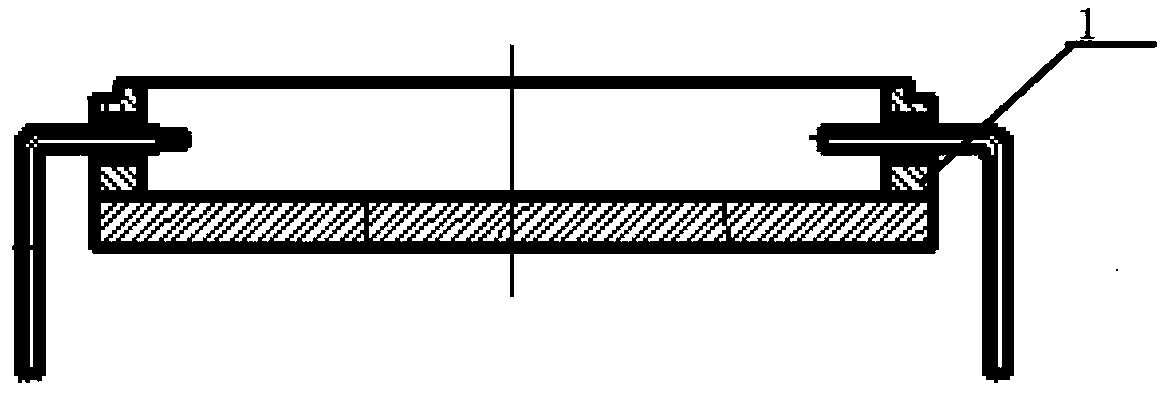

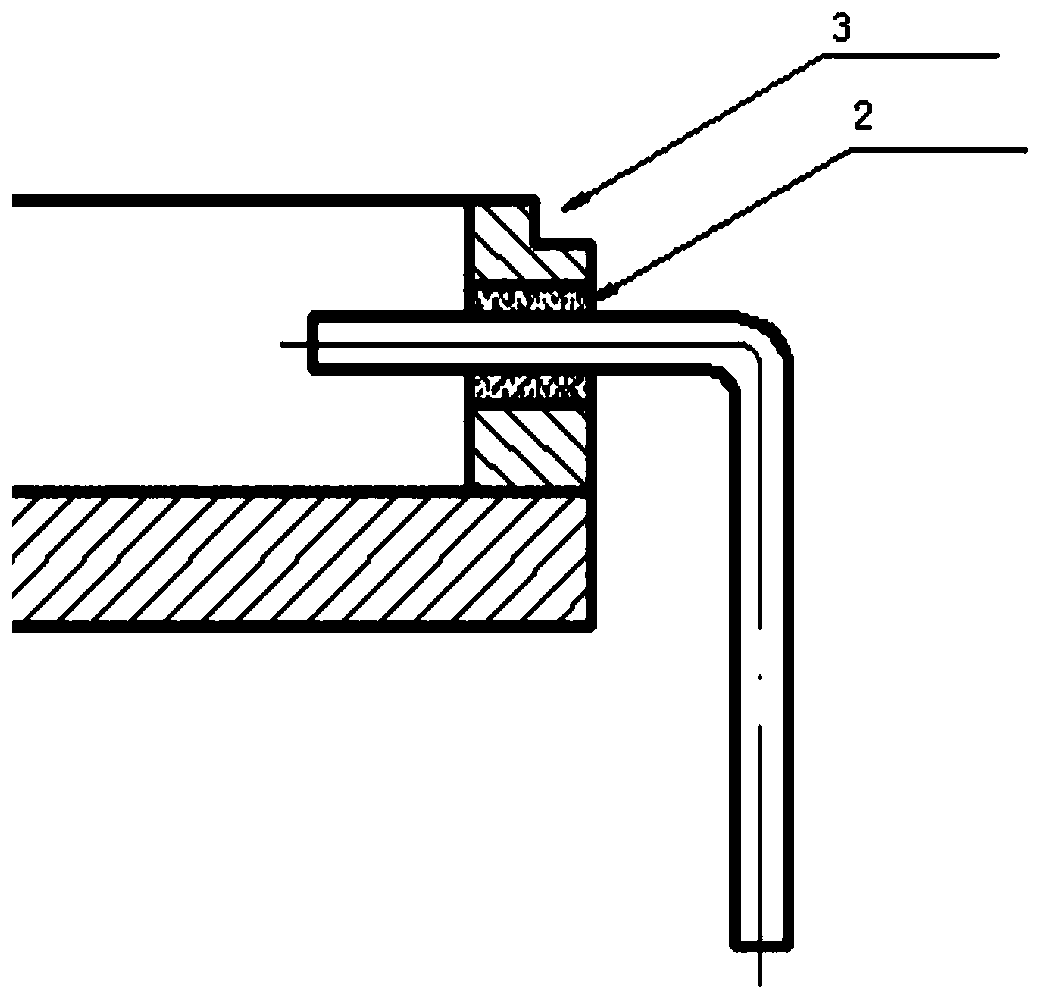

[0023] Embodiment 1: as figure 1 , figure 2 and image 3 A hybrid integrated circuit case is shown, including a side wall 1 of the case and a plurality of insulator mounting holes embedded in the side wall 1 of the case, glass insulators 2 are installed in the mounting holes of the insulator; the pressure-bearing end of the side wall 1 of the case Elastic pressure strips 3 are provided;

[0024] On the basis of the traditional integrated circuit case, four elastic stress bars 3 are arranged on the pressure-bearing end faces of the four side walls 1 of the case. The stress of the wall 1 ensures that the glass insulator 2 will not be damaged by the stress conducted by the side wall 1 of the shell and cause cracks.

Embodiment 2

[0025] Embodiment 2: On the basis of Embodiment 1, the stiffness coefficient of the elastic stress strip 3 is smaller than that of the side wall 1 of the casing, so when the circuit casing is installed, it is ensured that the elastic stress strip 3 is deformed first.

Embodiment 3

[0026] Embodiment 3: On the basis of Embodiment 2, the elastic stress strip 3 is integrated with the shell side wall 1 , and the elastic stress stress strip 3 forms a stepped structure with the end of the shell side wall 1 .

[0027] Now take the glass insulator 2 as an example to describe this technical solution in detail: the height of the side wall 1 of the integrated circuit shell is 8mm, and the height of the side wall 1 of the normal thickness is 7mm, the thickness is 2.5mm, and the step-like elasticity The bead 3 should have a height of 1mm and a thickness of 1.25mm.

[0028] The tensile strength of the glass is 3.4*10-7Pa. When the mechanical stress on the glass insulator 2 is greater than this tensile strength, the glass insulator 2 will crack. Use the traditional standard integrated circuit shell to simulate the installation status of the analog circuit shell. , the measured stress around the glass insulator 2 reaches 6.0*10-7Pa, mechanical stress 6.0*10-7Pa>tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com