Novel structural aluminum alloy wheel for heavy vehicles

A new type of structure, heavy-duty vehicle technology, applied in vehicle parts, rims, transportation and packaging, etc., can solve the problems of easy cracking of aluminum alloy wheel lock ring grooves, inconvenient disassembly and assembly, and heavy weight, and achieve good self-locking performance. The effect of operating convenience, improving convenience of use, and reducing cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

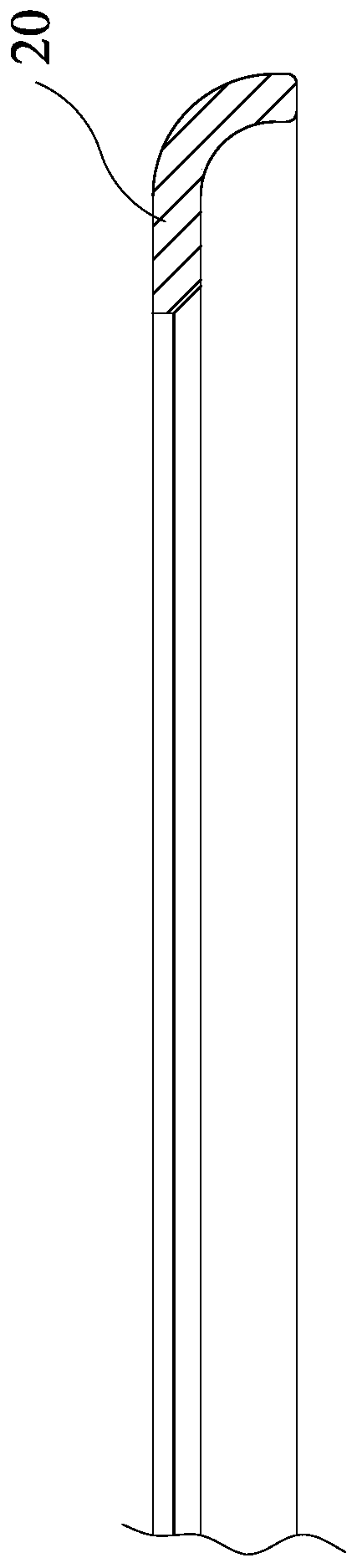

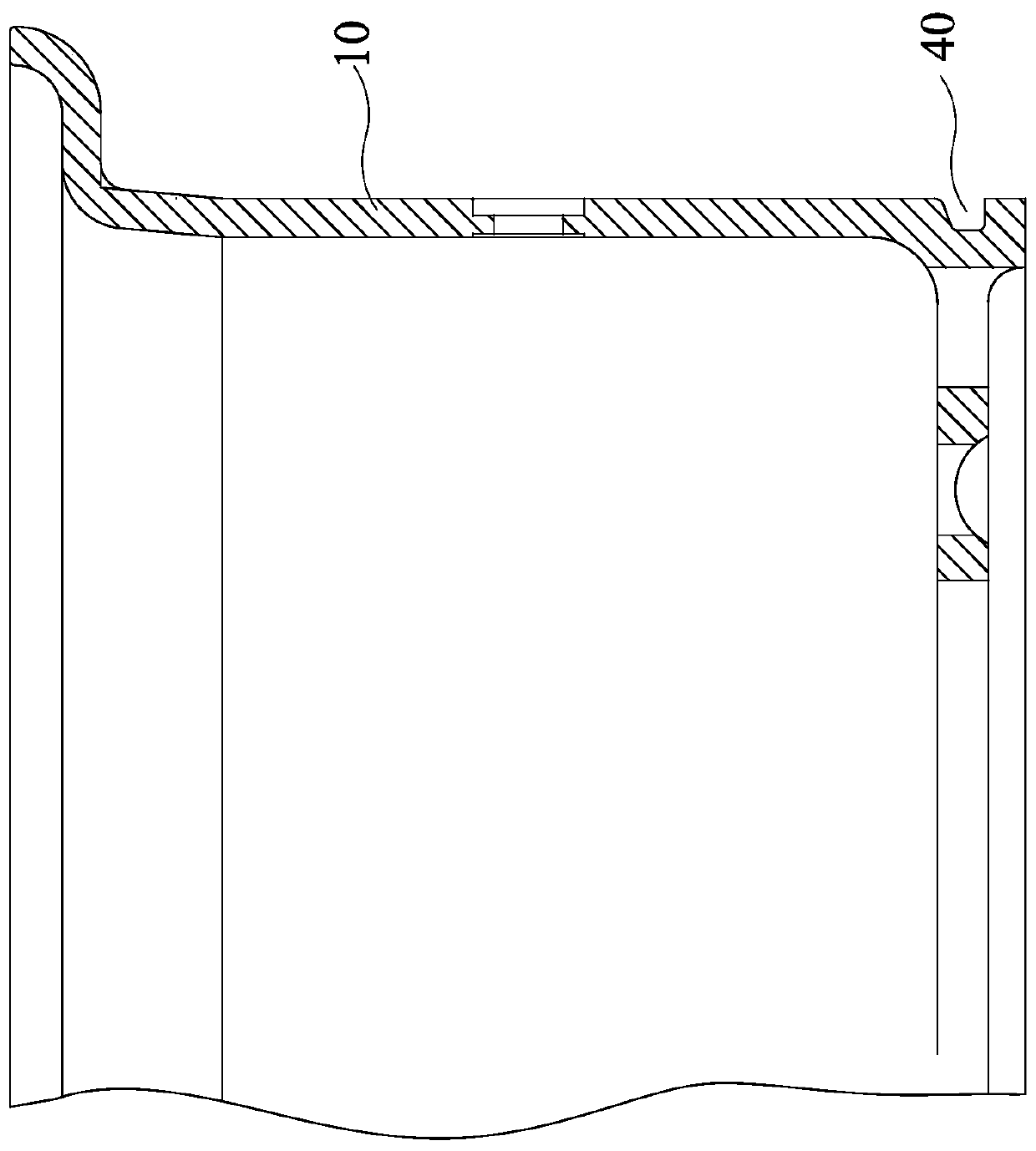

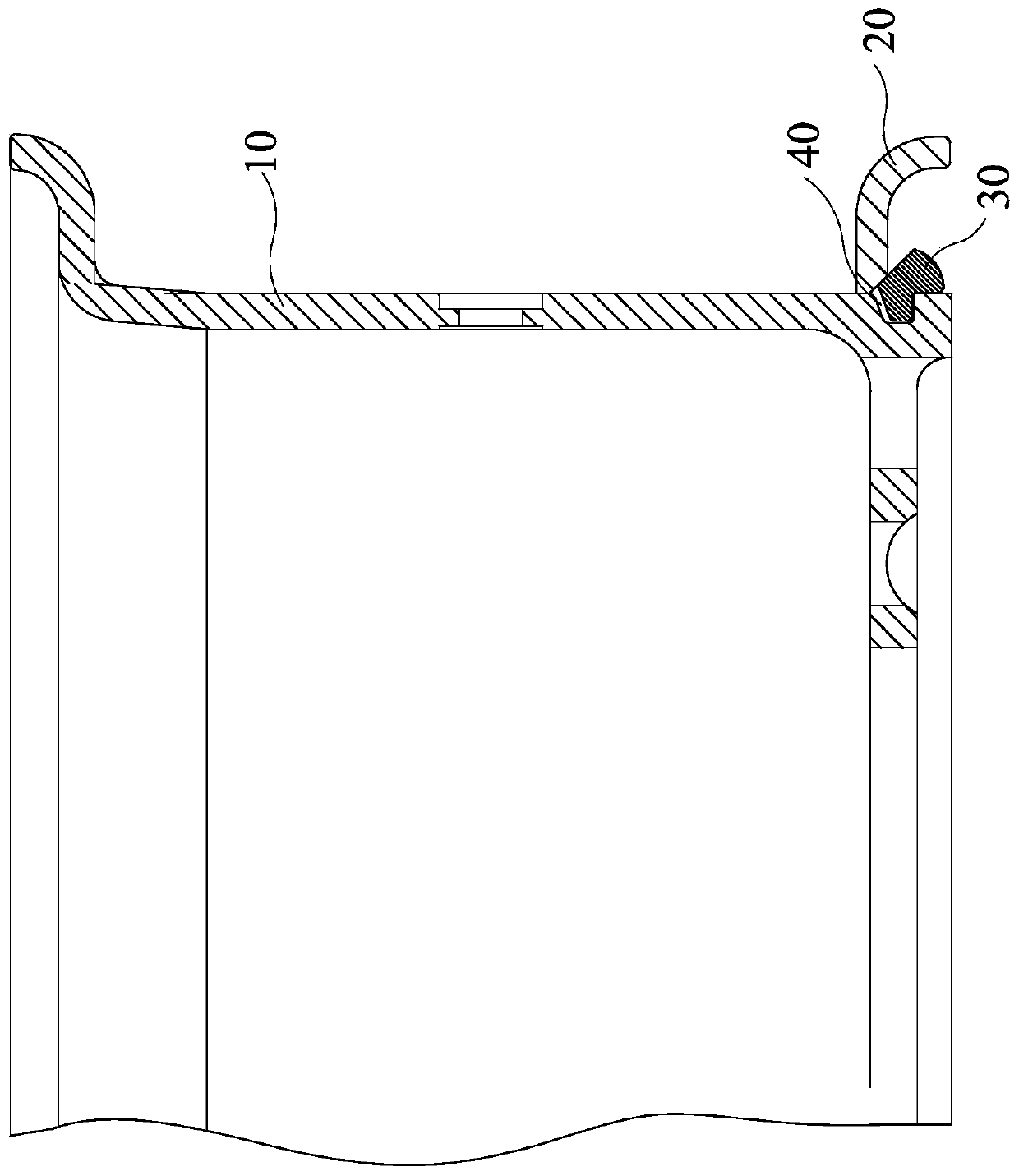

[0029] A new type of structural aluminum alloy wheel for heavy vehicles disclosed by the present invention, see Figure 4-8 ,

[0030] It includes an aluminum alloy rim 1 and an aluminum alloy rim 2, and the aluminum alloy rim 2 is close to the side where the aluminum alloy rim 1 is mounted with a tire.

[0031] The inner side of the aluminum alloy rim 2 is provided with a protruding ring 22, the inner side of the protruding ring 22 has an internal thread 21, the outer edge of the aluminum alloy rim 1 has an external thread 11 matching the internal thread 21, and the aluminum alloy rim 2 is detachable through threaded connection Installed on the aluminum alloy rim 1. The protruding ring 22 makes the overall structure more stable and ensures the strength of the threaded connection.

[0032] Preferably, the threaded connection adopts a zigzag thread, and the angles α and β between the left tooth surface and the right tooth surface of the zigzag thread and the vertical plane ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com