A magnetic pulse connection device, method and eddy current damper for double-layer circular tubes

A connecting device and magnetic pulse technology, applied in auxiliary devices, applications, welding equipment, etc., can solve the problems of large stress gradient of intermetallic compounds, poor formability of aluminum alloys, failure of aluminum alloys, etc., to achieve good promotion prospects and improve processing flexibility. , the effect of no condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

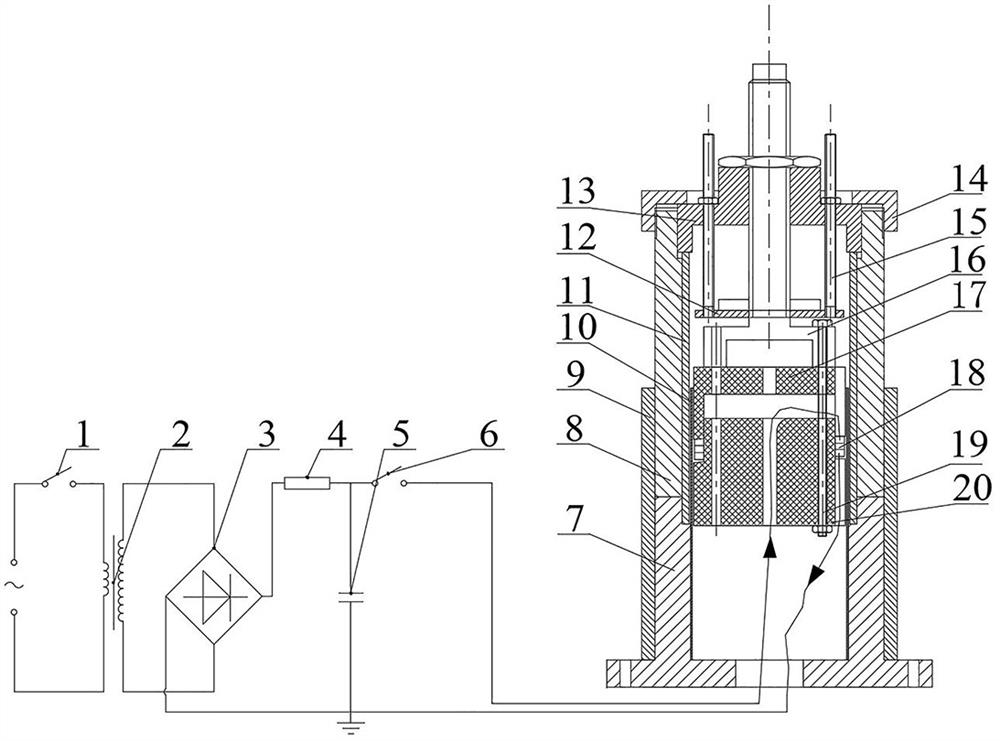

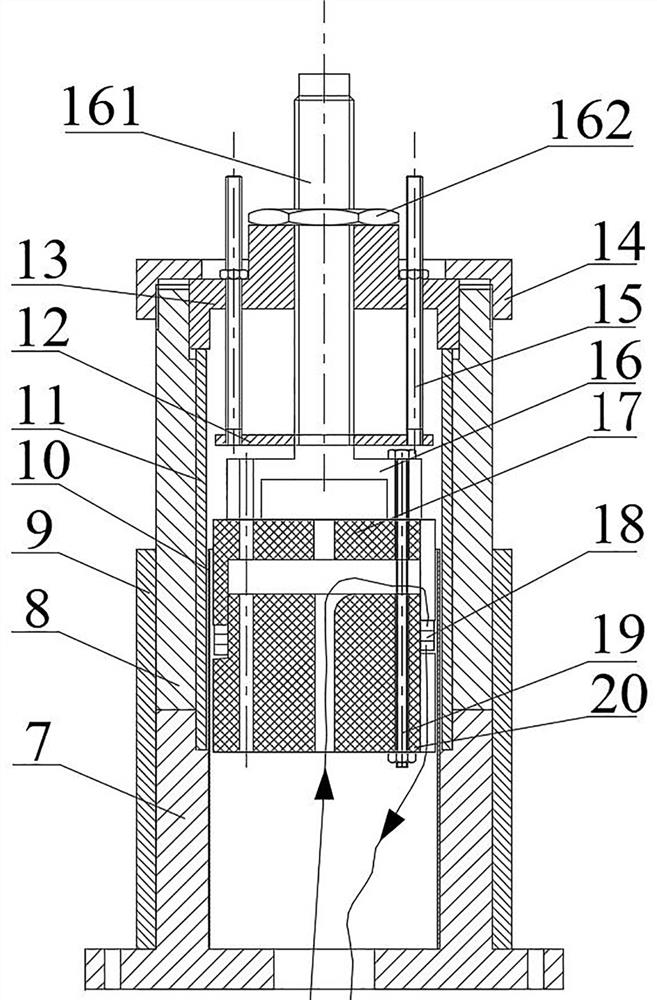

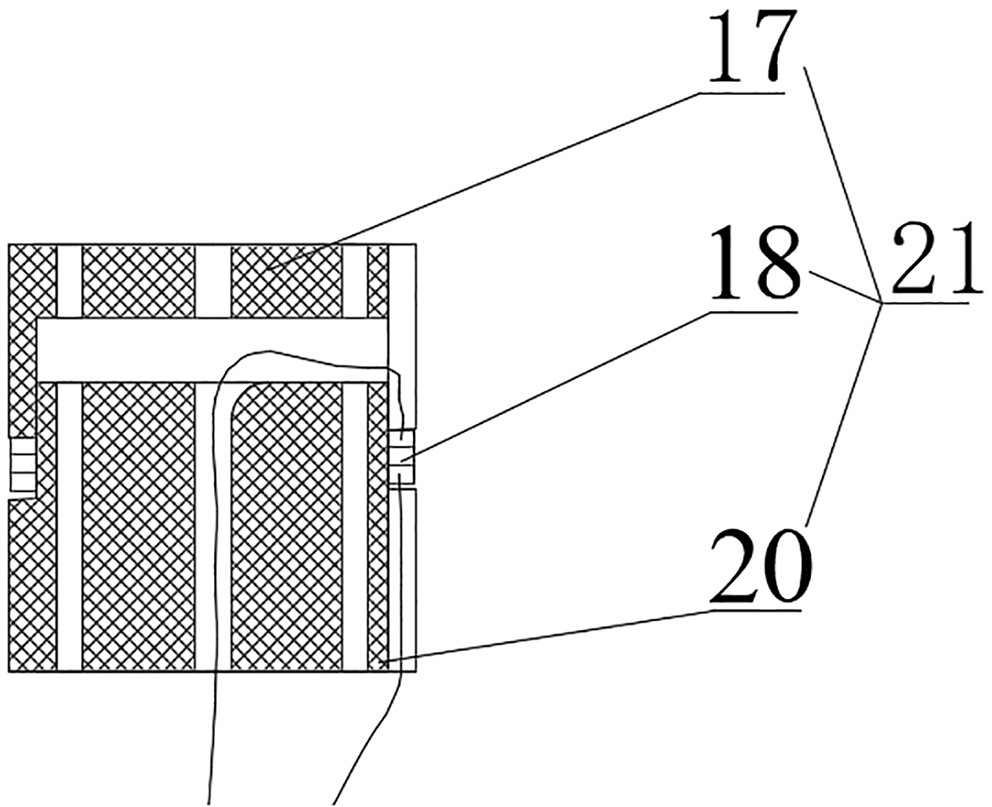

[0091] see Figure 1-3 The magnetic pulse connecting device for double-layer circular tubes provided in this embodiment is a magnetic pulse welding device for aluminum inner tubes and steel outer tubes in a double-layer circular tube axial force eddy current damper with a coil as an inductor, Including: charging switch 1, step-up transformer 2, high-voltage rectifier 3, current limiting resistor 4, capacitor 5, discharge switch 6, inner tube support 7, outer tube support 8, protective sleeve 9, inner tube 10, outer tube 11, Limit support 12, inner pressure plate 13, outer pressure plate 14, screw rod 15, flange 16, core cover 17, turn wire 18, insulating bolt 19, mandrel 20, coil inductor 21.

[0092] Specifically, such as figure 1 , close the charging switch 1, the transformer 2 will raise the AC voltage from the power grid to several thousand volts, the high-voltage rectifier 3 will convert the AC into DC, and charge the capacitor 5 after reducing the loop current through t...

Embodiment 2

[0113] see Figure 25, the technical solution provided by this embodiment is basically the same as that of Embodiment 1, the difference is that the diameter of the outer tube 11 is changed, and an annular groove 111 is opened on the inner wall of the overlapping position of the outer tube 11, and the first stage of the outer tube support 8 is changed. The inner diameter of the stepped hole changes the discharge energy.

[0114] Specifically, the inner tube 10 is made of 6063 aluminum alloy, with an outer diameter of 116 mm, a wall thickness of 1 mm, and a height of 150 mm. The material of the outer tube 11 is Q235 steel, with an outer diameter of 126 mm, a wall thickness of 5 mm, and a height of 150 mm. A ring groove with a width of 4mm and a depth of 1mm is set at 48mm. The length of the overlapping area of the inner and outer tubes is 100mm. The inner and outer tubes are in contact. Number 3, the outer diameter of the coil is 110mm, the axial length of the effective worki...

Embodiment 3

[0117] see Figure 26-28 , the technical solution provided by this embodiment is basically the same as that of Embodiment 1, the difference is that an insulating bakelite layer 23 and a magnetic collector 25 are set on the turn wire 18, and the insulating bolts 19 pass through the flange 16, Core cover 17, insulating bakelite layer 23, magnetic collector 25 are connected to mandrel 20;

[0118] Specifically, the inner tube 10 is made of 6063 aluminum alloy with an outer diameter of 116 mm, a wall thickness of 1 mm, and a height of 150 mm. The outer tube 11 is made of Q235 steel with an outer diameter of 128 mm, a wall thickness of 5 mm, and a height of 150 mm. 100mm, the gap between the inner and outer tubes is 1mm, and the inner diameter of the first step hole supported by the outer tube is 128mm.

[0119] Specifically, see Figure 28-38 , the magnetic collector-coil composite inductor 27 winds the turn wire 18 on the mandrel 20 made of insulating material, presses it tight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com