Antistatic epitaxial structure and manufacturing method thereof

An epitaxial structure and manufacturing method technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of weak anti-static capability of epitaxial structures, quantum well burnout, chip failure, etc., to improve electrostatic capability and prevent electrostatic breakdown. , the effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

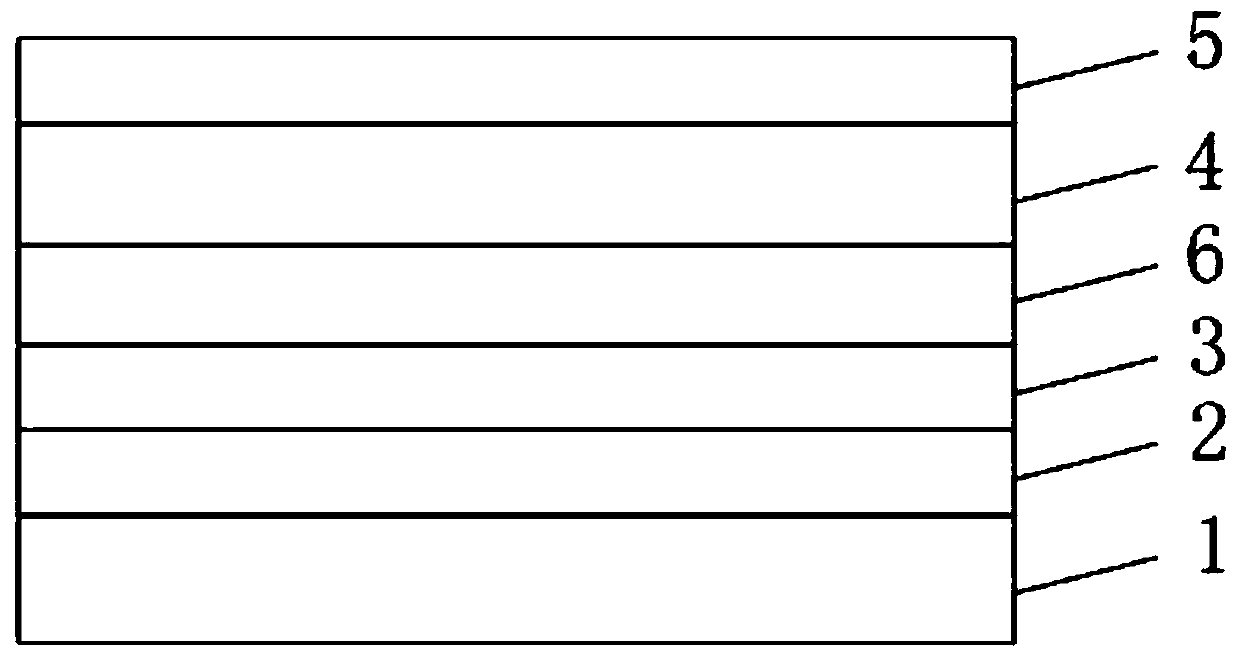

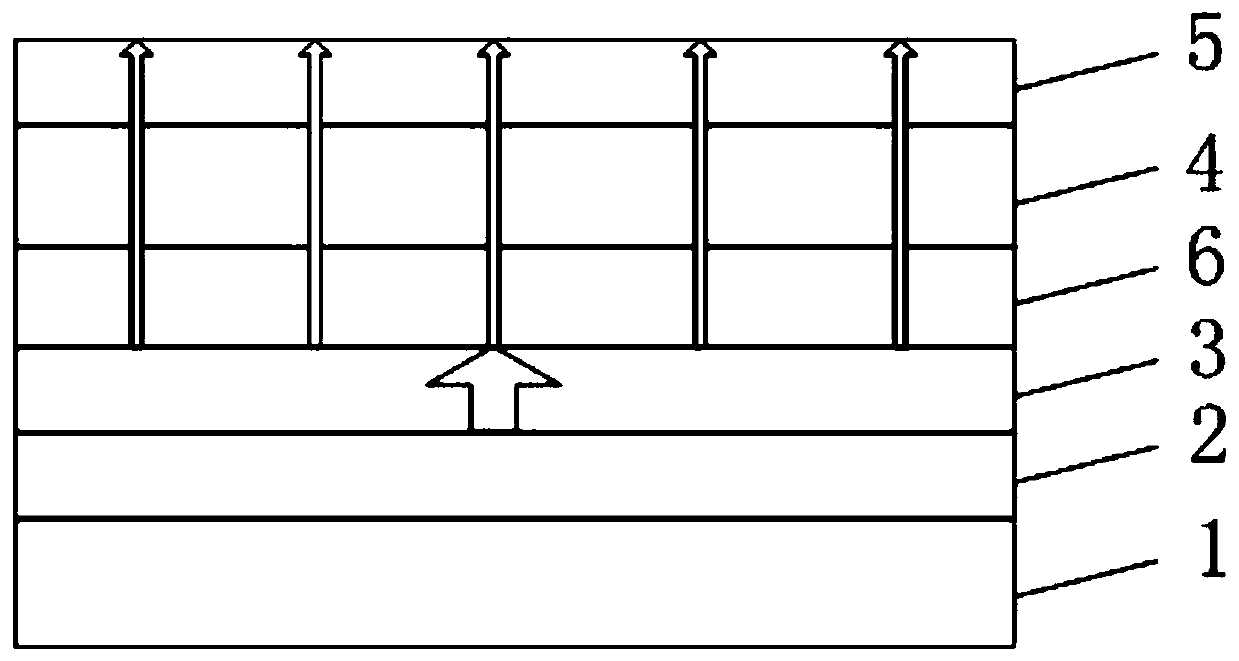

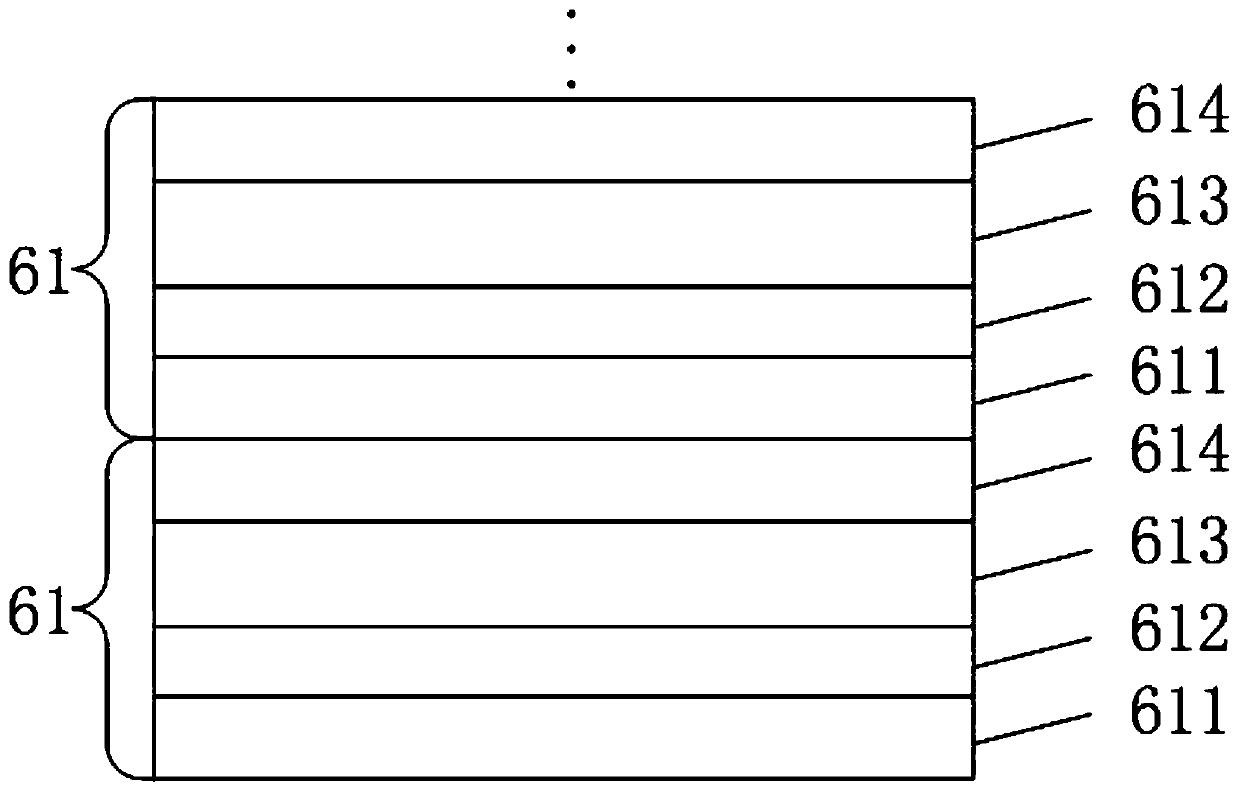

[0059] An antistatic epitaxial structure, comprising a buffer layer, an N-type GaN layer, an active layer and a P-type GaN layer sequentially arranged on a substrate, a composite layer is arranged between the N-type GaN layer and the active layer, The composite layer includes five GaN layers with varying silicon concentration, and the GaN layer with varying silicon concentration includes a first GaN layer, a second GaN layer disposed on the first GaN layer, and a third GaN layer disposed on the second GaN layer. layer, and a fourth GaN layer arranged on the third GaN layer, the doping concentration of silicon in the first GaN layer is 0, the doping concentration of silicon in the second GaN layer is 3E+15mor, the The doping concentration of silicon in the third GaN layer is 3E+19 mor, and the doping concentration of silicon in the fourth GaN layer is 3E+15 mor.

Embodiment 2

[0061] An antistatic epitaxial structure, comprising a buffer layer, a U-type GaN layer, an N-type GaN layer, an active layer and a P-type GaN layer sequentially arranged on a substrate, the U-type GaN layer and the N-type GaN layer A composite layer is provided between them, and the composite layer includes 5 layers of GaN layers with varying silicon concentrations, and the GaN layers with varying silicon concentrations include a first GaN layer, a second GaN layer disposed on the first GaN layer, and a GaN layer disposed on the second GaN layer. The third GaN layer on the layer, and the fourth GaN layer arranged on the third GaN layer, the doping concentration of silicon in the first GaN layer is 0, and the doping concentration of silicon in the second GaN layer is 3E+15 mor, the doping concentration of silicon in the third GaN layer is 3E+19 mor, and the doping concentration of silicon in the fourth GaN layer is 3E+15 mor.

Embodiment 3

[0063] An antistatic epitaxial structure, comprising a buffer layer, a U-type GaN layer, an N-type GaN layer, an active layer and a P-type GaN layer sequentially arranged on a substrate, between the N-type GaN layer and the active layer A composite layer is provided, and a composite layer is provided between the U-type GaN layer and the N-type GaN layer, and the composite layer includes 5 layers of GaN layers with silicon concentration changes, and the GaN layers with silicon concentration changes include the first GaN layer, the A second GaN layer on the first GaN layer, a third GaN layer on the second GaN layer, and a fourth GaN layer on the third GaN layer, the doping of silicon in the first GaN layer concentration is 0, the doping concentration of silicon in the second GaN layer is 3E+15mor, the doping concentration of silicon in the third GaN layer is 3E+19mor, and the doping concentration of silicon in the fourth GaN layer is equal to It is 3E+15mor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com