SLM (selective laser melting) method for processing horizontal suspended structure without longitudinal supports

A technology of vertical support and laser melting, which is applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve problems such as difficult processing, and achieve the effects of reducing production costs, enhancing capabilities, and simplifying processing and post-processing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

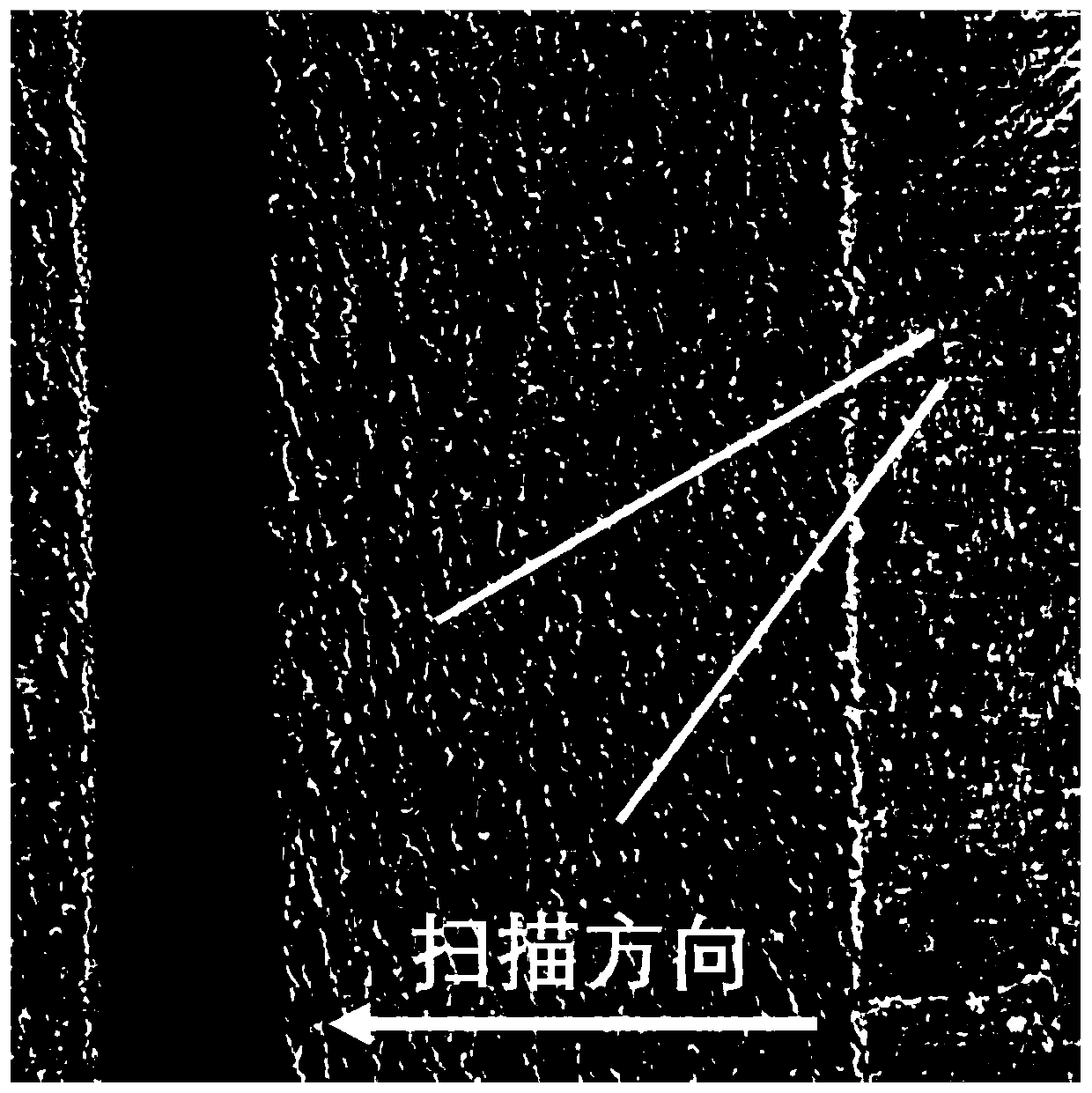

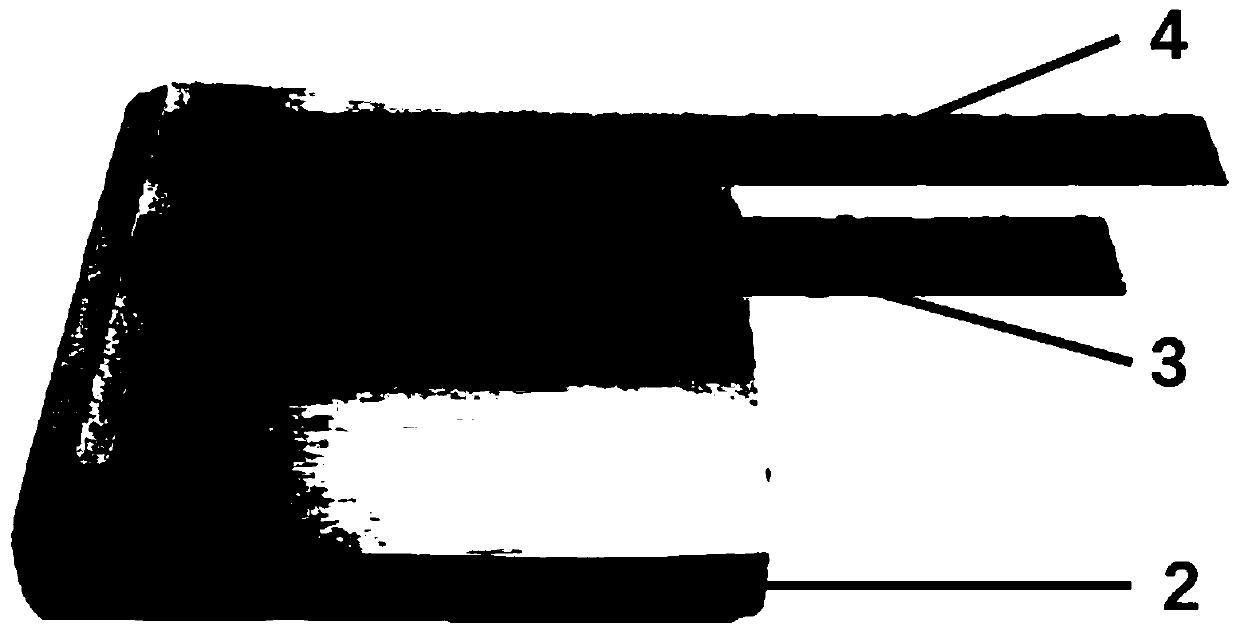

[0077] Example 1: Printing a large-span initial horizontal suspension layer

[0078] Such as figure 2 As shown, first, a small cuboid with a size of 40mm×2.5mm×4mm is printed on a stainless steel substrate 2 with a size of 50mm×50mm×6mm using conventional process parameters; then a small cuboid with a size of 70mm× 8mm first initial horizontal suspension layer 3 and a second initial horizontal suspension layer 4 with a size of 80mm×8mm; figure 2 Shown is the actual image of the large-span initial horizontal suspended layer after printing; the process parameters are: continuous laser output mode, laser power 40W, spot diameter 90-100μm, scanning speed 0.1m / s, scanning distance 65μm, layer thickness 30μm, The number of processing layers is 1 layer. This example shows that the method of the present invention can stably process an initial horizontal suspended layer with a large span and a certain mechanical strength.

Embodiment 2

[0079] Example 2: To print a cavity structure with an internal flat top of 40mm×20mm, proceed as follows

[0080] Step a, such as image 3 As shown, the back-shaped base is printed on a stainless steel substrate 2 with a size of 50mm×50mm×6mm using conventional process parameters, and the number of processing layers is 100; the outer size of the printing area is 45mm×25mm, the inner size is 40mm×20mm, and the wall thickness 2.5mm.

[0081] Step b, processing the initial layer of suspended flat top. The process parameters are set as follows: continuous laser output mode, laser power 40W, spot diameter 90-100μm, scanning speed 0.1m / s, scanning distance 65μm, layer thickness 30μm, processing layer 1 layer;

[0082] Step c, continue to process the two-layer back-shaped structure with the process parameters of step a

[0083] Step d, repairing the upper surface of the suspended layer is completed in three steps.

[0084] The first step: process parameters: continuous laser outp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com