Excess injection correction device applied to injection mold

A technology of injection molds and correction devices, which is applied in the field of over-injection correction devices, can solve problems such as difficulty in ensuring injection volume, achieve the effects of reducing time, highlighting single corrections, and optimizing production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

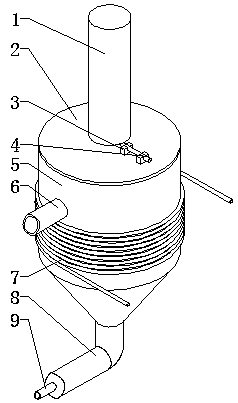

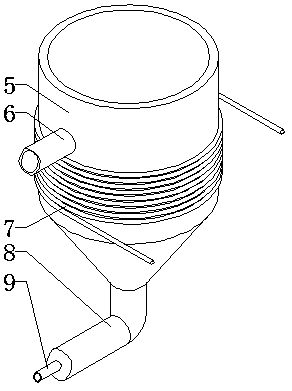

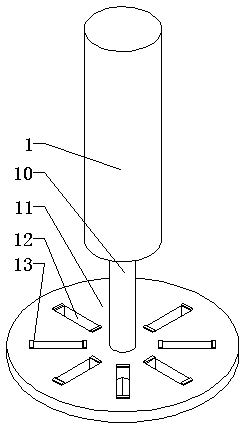

[0043] see Figure 1-3 , an over-injection correcting device applied to an injection mold, comprising an injection chamber 5, which is made of stainless steel and used to contain injection liquid, and a lifting hydraulic cylinder 1 is installed above the injection chamber 5 to provide Injection molding pressure, the lifting hydraulic cylinder 1 includes a telescopic rod 10, the outer side of the telescopic rod 10 is covered with a hydraulic cylinder block, the hydraulic cylinder block is fixed above the injection molding chamber 5, and the hydraulic cylinder block is provided with a pipe interface, the hydraulic pressure The cylinder block is connected with a hydraulic oil pipeline through a pipeline interface, and several hydraulic oil pipelines form a hydraulic oil circuit. A pressure applying plate 11 is installed on the top of the telescopic rod 10, and the pressure applying plate 11 is transitionally matched with the inner side wall of the injection molding warehouse 5, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com