Three-layer high-water-resistance degradable packing material and preparation method thereof

A technology for packaging materials and degradable materials, which is applied in the field of three-layer high-resistance water-degradable packaging materials and their preparation, and achieves the effects of simple and effective method, easy industrialization, and good biodegradability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

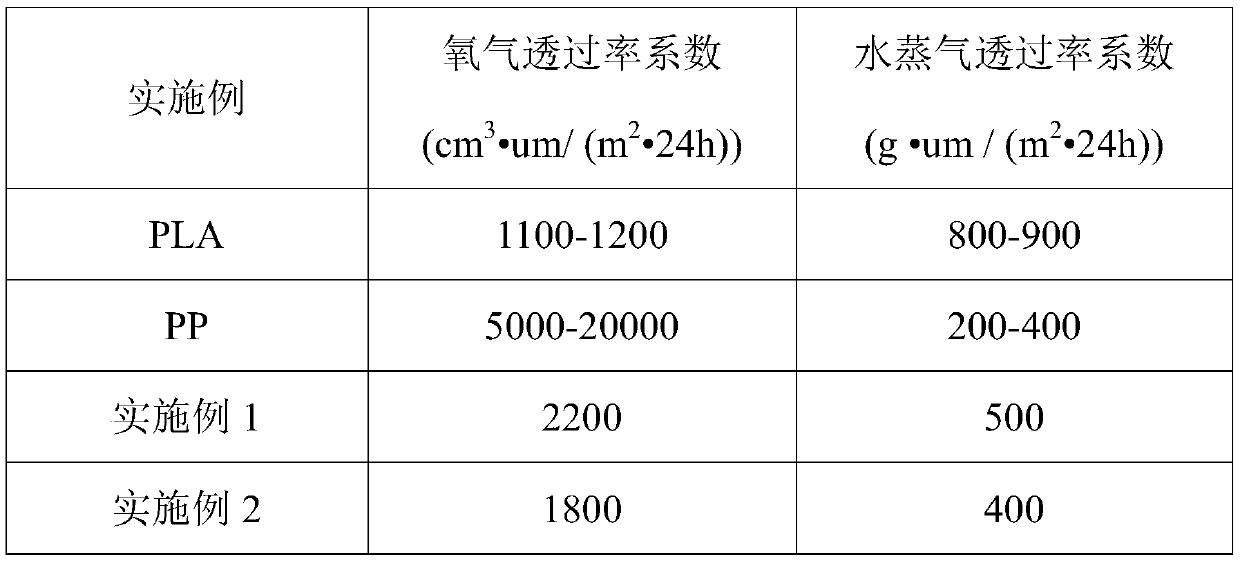

Embodiment 1

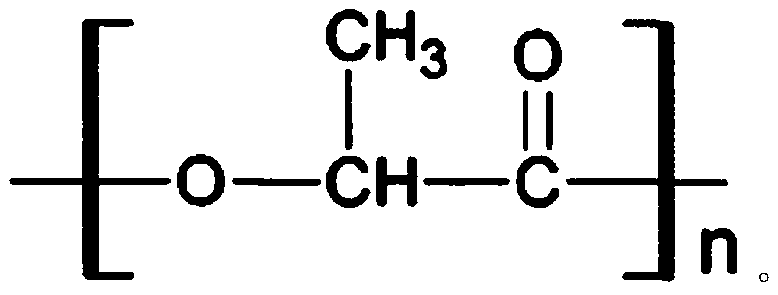

[0035] The three-layer high-resistance water-degradable packaging material provided in this embodiment uses the biodegradable material polylactic acid film as the substrate, and a barrier-reinforced polypropylene film is provided on both sides of the polylactic acid film to form a polypropylene (PP) / Polylactic acid (PLA) / polypropylene (PP) composite film.

[0036] in:

[0037] The polylactic acid film has a number average molecular weight of 50,000 to 250,000 g / mol.

[0038] The thickness of the polylactic acid film was 30 μm.

[0039] The thickness of the polypropylene film was 1.5 μm.

[0040] The polypropylene film is two layers.

[0041] The preparation method of the three-layer high-resistance water-degradable packaging material is as follows:

[0042] (1) Polypropylene resin is plasticized by a screw machine extruder;

[0043] (2) Set the temperature and cast the polypropylene onto the polylactic acid film;

[0044] (3) Cool and dry the polylactic acid film aft...

Embodiment 2

[0050] The three-layer high-resistance water-degradable packaging material provided in this embodiment uses the biodegradable material polylactic acid film as the substrate, and a barrier-reinforced polypropylene film is provided on both sides of the polylactic acid film to form a polypropylene (PP) / Polylactic acid (PLA) / polypropylene (PP) composite film.

[0051] in:

[0052] The polylactic acid film has a number average molecular weight of 100,000 to 200,000 g / mol.

[0053] The thickness of the polylactic acid film was 50 μm.

[0054] The thickness of the polypropylene film was 2.0 μm.

[0055] The polypropylene film is a single layer.

[0056] The preparation method of the three-layer high-resistance water-degradable packaging material is as follows:

[0057] (1) Polypropylene resin is plasticized by a screw machine extruder;

[0058] (2) Set the temperature and cast the polypropylene onto the polylactic acid film;

[0059] (3) cooling and drying the cast polylactic...

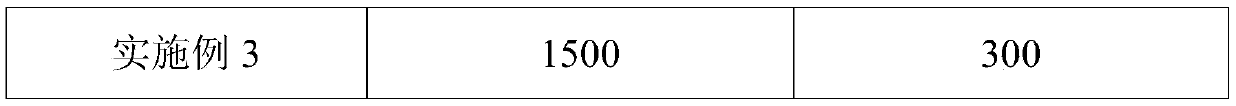

Embodiment 3

[0065] The three-layer high-resistance water-degradable packaging material provided in this embodiment uses the biodegradable material polylactic acid film as the substrate, and a barrier-reinforced polypropylene film is provided on both sides of the polylactic acid film to form a polypropylene (PP) / Polylactic acid (PLA) / polypropylene (PP) composite film.

[0066] in:

[0067] The polylactic acid film has a number average molecular weight of 150,000 to 180,000 g / mol.

[0068] The thickness of the polylactic acid film was 90 μm.

[0069] The thickness of the polypropylene film was 2.5 μm.

[0070] The polypropylene film is a single layer.

[0071] The preparation method of the three-layer high-resistance water-degradable packaging material is as follows:

[0072] (1) Polypropylene resin is plasticized by a screw machine extruder;

[0073] (2) Set the temperature and cast the polypropylene onto the polylactic acid film;

[0074] (3) cooling and drying the cast polylact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com