Ship air scuttle arranging method and ship

A technology for portholes and ships, which is applied to the opening method of ship portholes and the field of ships, can solve the problems of increasing the cost of portholes, the accuracy and aesthetics of the overall window hole cannot meet the requirements, and the poor aesthetics of ships, so as to improve the accuracy and aesthetics and reduce the cost of portholes. The effect of modifying work and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

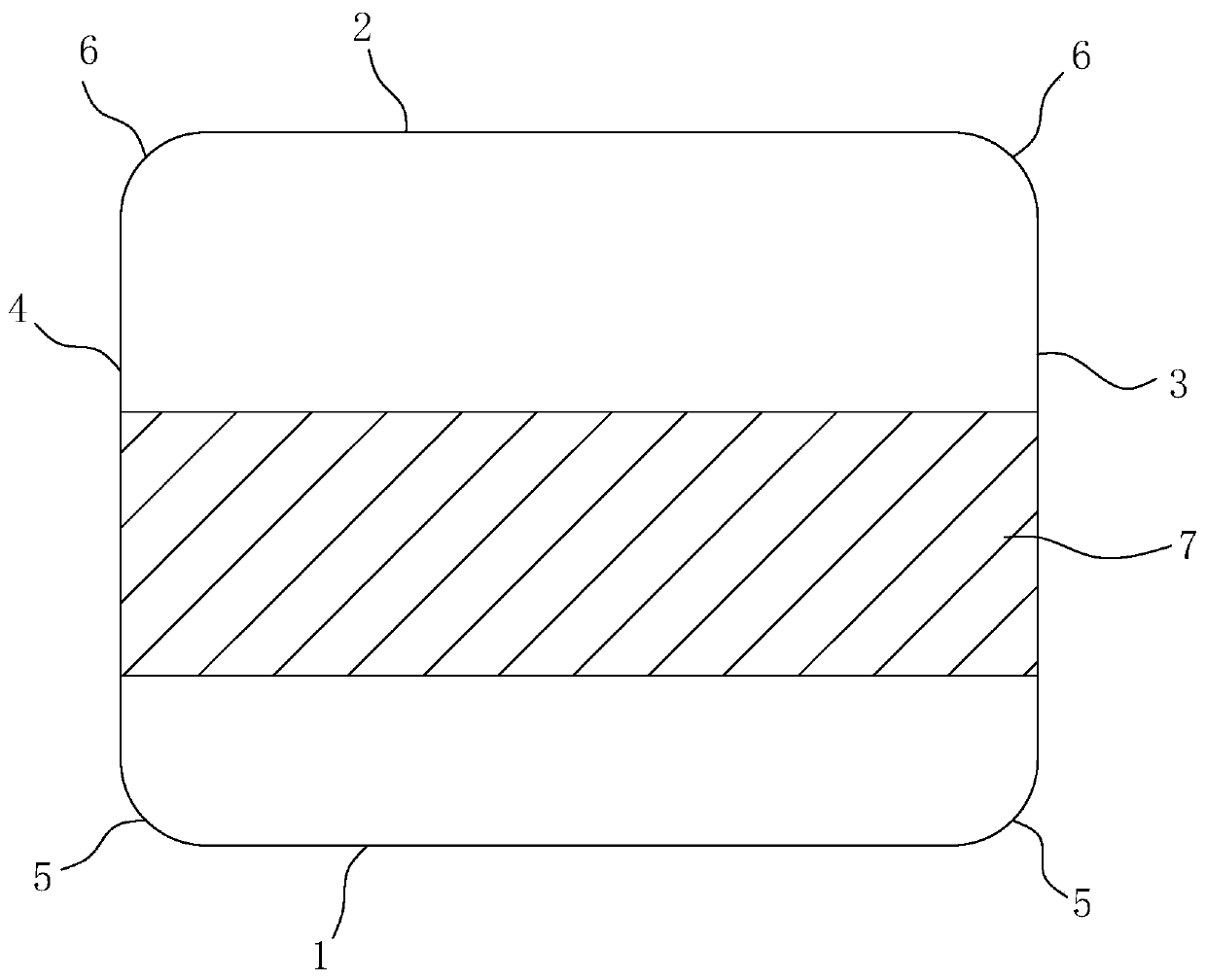

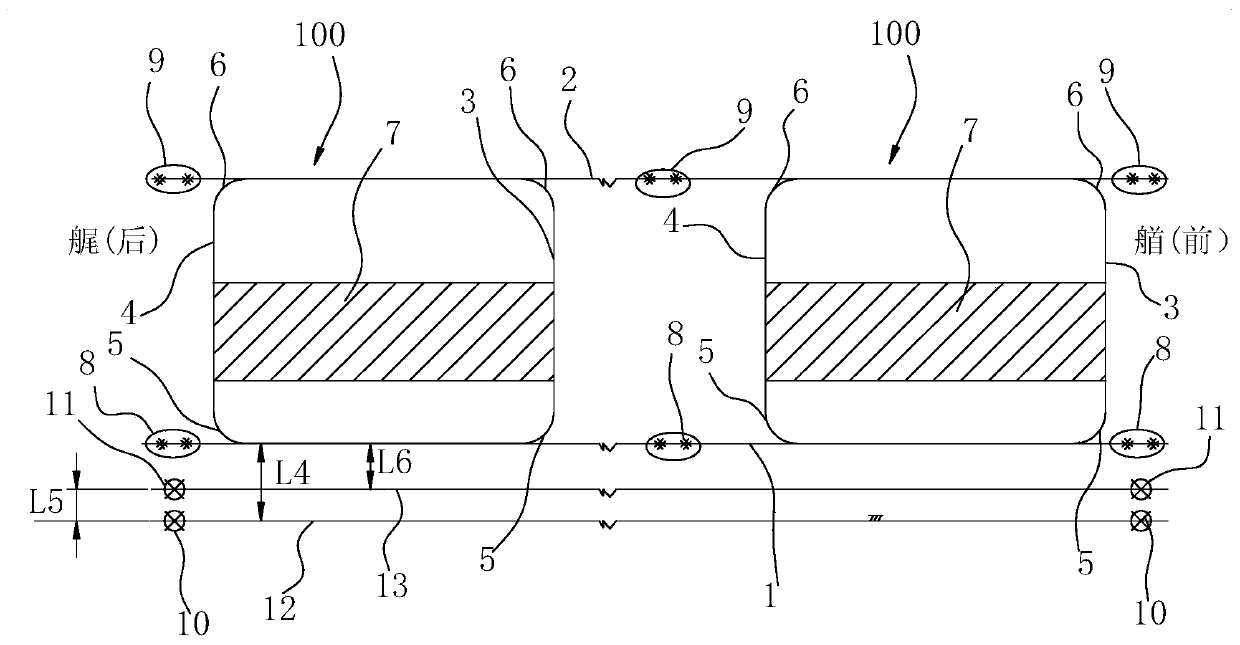

[0043] Such as Figure 1 to Figure 3 As shown, the present invention provides a method for opening portholes 100 of a ship. After the hull is completely closed, the superstructure is integrally welded to the hull and the pyrotechnic work is completed, each window of the superstructure is marked on the side outer plate respectively. The lower edge line 1, the upper edge line 2, the front edge line 3 and the rear edge line 4 of the hole, and the lower edge line 1 corresponding to each of the window holes on the same side and the same layer are all distributed on the same horizontal line, The upper edge lines 2 corresponding to the windows on the same side and the same layer are kept distributed on the same horizontal line, and the front edge lines 3 and the rear edge lines 4 are kept vertically distributed. In the present invention, after the hull is closed, the superstructure is integrally welded to the hull, and the pyrotechnic work is completed, the lower edge line 1, upper e...

Embodiment 2

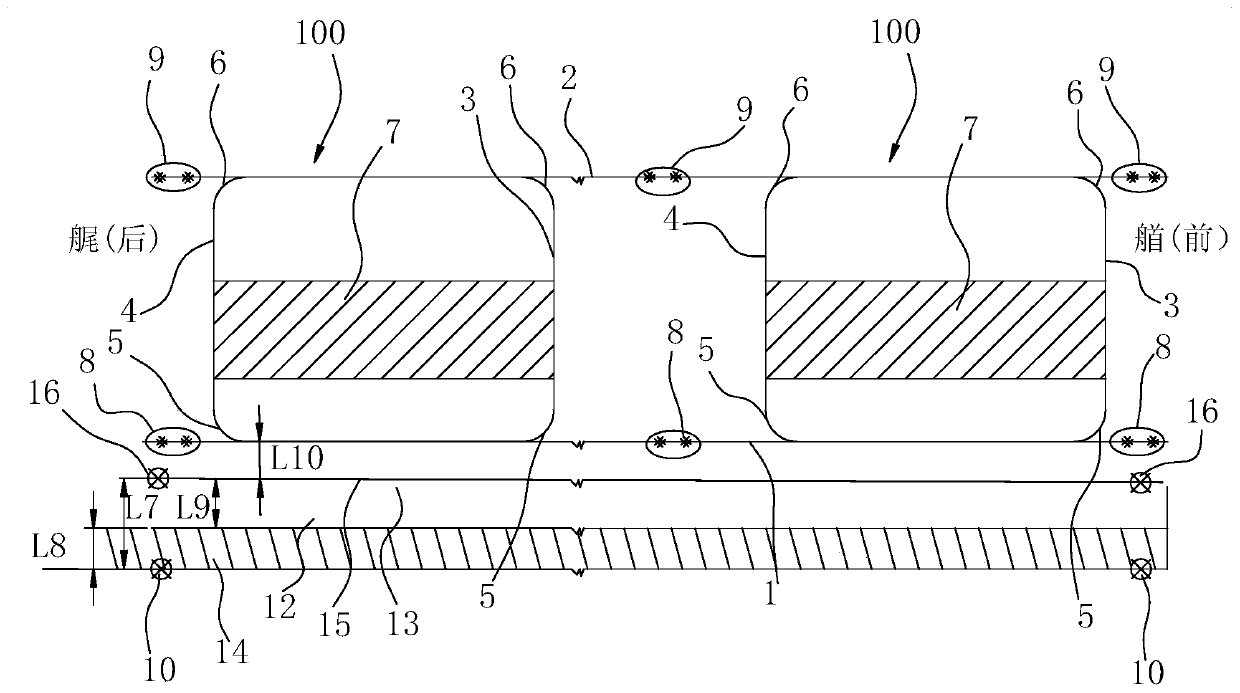

[0064] Such as image 3As shown, wherein, the reference numerals in the drawings in this embodiment partly extend the reference numerals in the drawings in Embodiment 1. The present embodiment is basically the same as the present embodiment, the difference being that the opening method of the porthole 100 described in the present embodiment is used for marking the lower edge line 1 of the outer corridor at the bottom of the ship window, and the thickness of the deck 14 is upward, namely The deck theoretical line 12 is located on the lower surface of said deck. Specifically, the method also includes step S12, determining two positioning points of the deck theoretical line 12 at the intersection of the deck 14 and the side shell plate, respectively obtaining two positioning points 10 of the deck theoretical line, and two The deck theoretical line positioning points 10 are located on the same side shell plate and below the window holes at the front and rear ends of the same ship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com