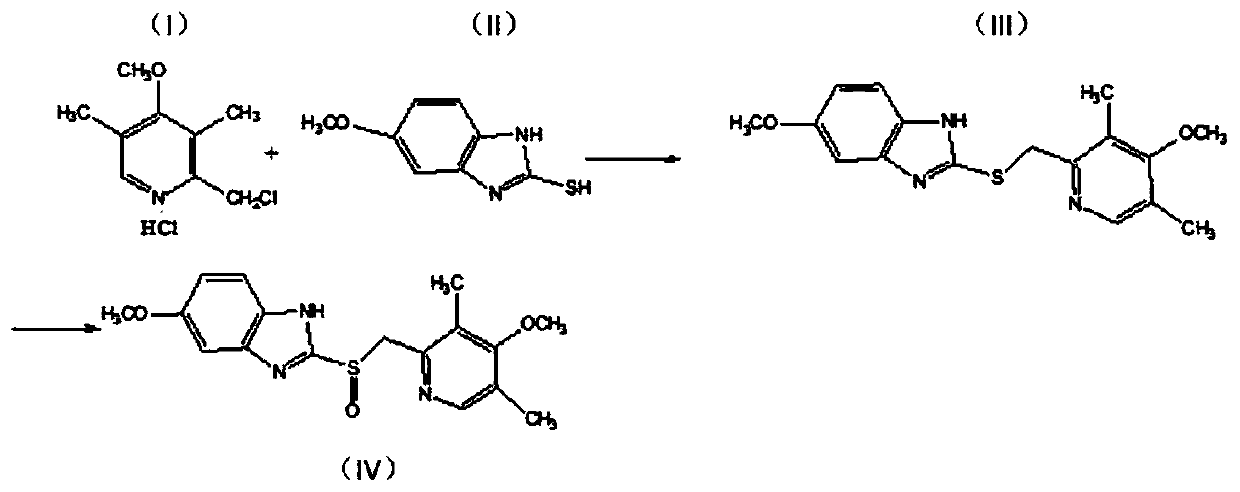

Synthetic technology of omeprazole

A technology of omeprazole and synthesis process, applied in the field of omeprazole synthesis technology, can solve the problem of high impurities, and achieve the effects of controlling the conversion of impurities, reducing costs and reducing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A kind of Omeprazole synthetic technique, it comprises the following steps:

[0083] (1) Add 37g of chloride into 185ml of methanol, stir and dissolve to obtain a chloride solution.

[0084] (2) Add 14 g of sodium hydroxide into 185 ml of methanol, stir to dissolve, add 30 g of benzimidazole derivatives, and obtain an alkaline solution of benzimidazole derivatives.

[0085] The chloride solution obtained in the step (1) is added dropwise to the alkaline solution of the benzimidazole derivative to cause condensation reaction between the two.

[0086] Wherein, during the dropping process, the temperature is controlled at 10°C to 20°C. After the dropwise addition, the temperature is controlled at 10°C to 20°C, and the stirring reaction is continued for 1 hour. After the condensation reaction is completed, the obtained reaction solution is cooled at 5°C to 10°C. Crystallization, centrifugal filtration, after washing the obtained precipitated crystal with 1L of purified wat...

Embodiment 2

[0092] A kind of Omeprazole synthetic technique, it comprises the following steps:

[0093] (1) Add 37g of chloride into 185ml of methanol, stir and dissolve to obtain chloride solution.

[0094] (2) Add 14g of sodium hydroxide into 185ml of methanol, stir and dissolve, add 31g of benzimidazole derivatives to obtain an alkaline solution of benzimidazole derivatives.

[0095] The chloride solution obtained in the step (1) is added dropwise to the alkaline solution of the benzimidazole derivative to cause condensation reaction between the two.

[0096]Wherein, during the dropping process, the temperature is controlled at 10°C to 20°C. After the dropwise addition is completed, the temperature is controlled at 10°C to 20°C, and the stirring reaction is continued for 1 hour until the condensation reaction is completed, and the obtained reaction solution is cooled and crystallized at 5°C to 10°C. Centrifugal filtration, the obtained precipitated crystals were added to 70ml of metha...

Embodiment 3

[0102] A kind of Omeprazole synthetic technique, it comprises the following steps:

[0103] (1) Add 37g of chloride into 139ml of methanol, stir and dissolve to obtain a chloride solution.

[0104] (2) Add 13g of sodium hydroxide into 116ml of methanol, stir and dissolve, add 31g of benzimidazole derivatives to obtain an alkaline solution of benzimidazole derivatives.

[0105] The chloride solution obtained in the step (1) is added dropwise to the alkaline solution of the benzimidazole derivative to cause condensation reaction between the two.

[0106] Wherein, during the dropping process, the temperature is controlled at 10° C. to 20° C., after the dropwise addition is completed, the temperature is controlled at 10° C. to 20° C., and the stirring reaction is continued for 1 hour to obtain a reaction solution.

[0107] (3) Get 25ml of hydrogen peroxide with a mass concentration of 35% and 4ml of purified water to prepare hydrogen peroxide with a mass concentration of 30% as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com