Open hole staged fracturing construction method of dual-branch horizontal well

A technology of staged fracturing and construction method, which is applied in wellbore/well components, earthwork drilling, and fluid production, etc., can solve the problems of low operation efficiency, high construction cost, complicated construction process, etc., so as to reduce the cost of well construction , Avoid pressure problems, and broaden the effect of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

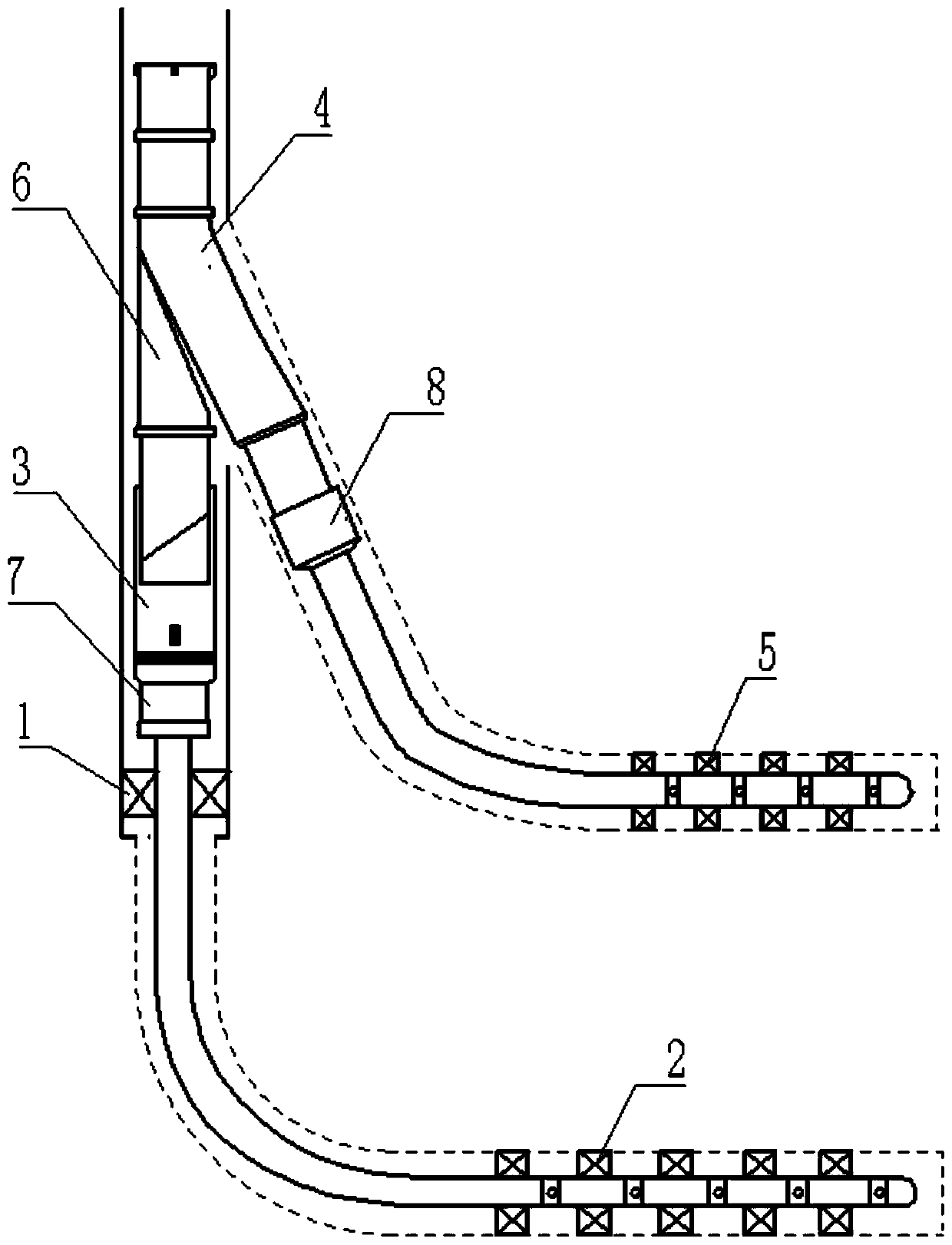

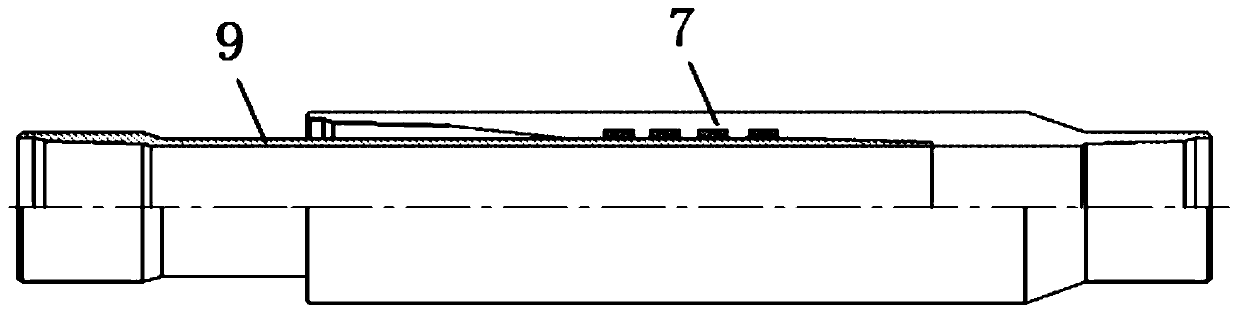

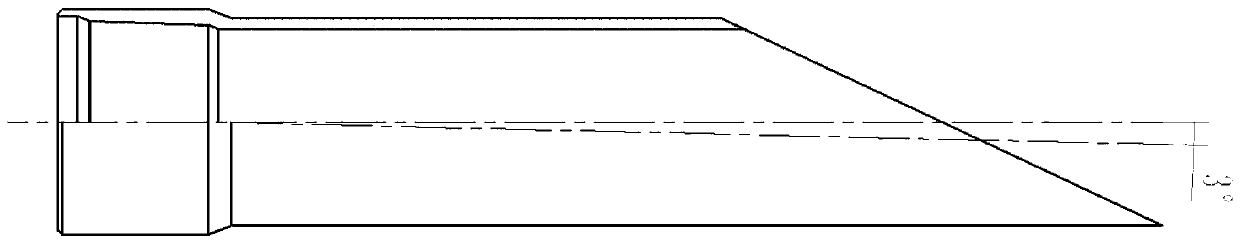

[0018] Such as figure 1 As shown, a construction method for open hole staged fracturing of a double-branch horizontal well, the steps of the method are as follows: firstly, the main wellbore is drilled, and a liner hanger 1 is used to lower the main hole open hole staged fracturing completion tool 2, The window opening system of running in the branch well is connected with the liner hanger 1, and the window opening construction and branch hole drilling are completed; Fracture completion tool 5 completes the window penetration of the main wellbore and branch wellbore; the main wellbore is run into the fracturing tie-back string, and the 3-degree bend-back seal plug 9 at the lower end of the fracturing tie-back string is first connected with the open hole section of the main wellbore The main wellbore fracturing tie-back sealing nipple 7 of the fracturing completion tool 2 forms a tie-back seal, such as figure 2 As shown, fracturing the main wellbore;

[0019] After the fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com