Novel high-pressure manifold device

A high-pressure manifold, a new type of technology, applied in the wellbore/well valve device, drill pipe, casing, etc., can solve the problems of low reliability and low flow rate, reduce erosion and wear, reduce vibration, and reduce variation. The effect of the diameter zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described in detail with reference to the accompanying drawings.

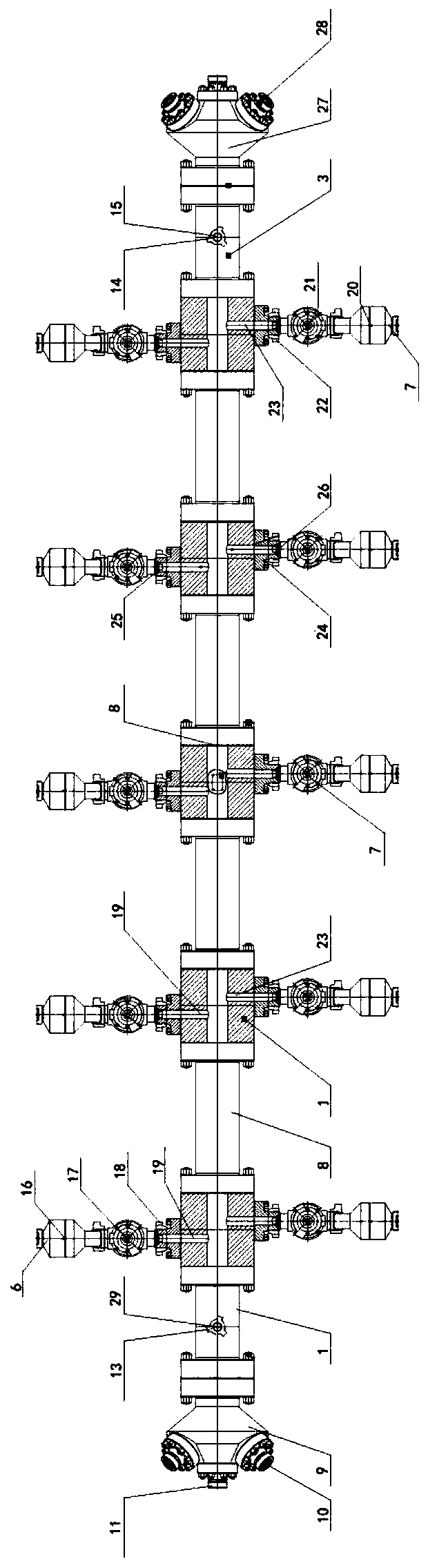

[0027] Such as figure 1 As shown, the new high-pressure manifold device of the present invention includes a straight central manifold, the rear end of the central manifold is provided with a discharge port, and the front end of the central manifold is provided with a serial inlet, the The upper rear end of the central manifold is vertically connected with a first liquid inlet channel 6 , and the lower front end of the central manifold is vertically connected with a second liquid inlet channel 7 .

[0028] Since the central manifold is in the shape of a straight line, compared with the ring-shaped high-pressure manifold device, the variable diameter area and friction loss of the central manifold are significantly reduced, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com