Fully automatic multi-device testing system and method for integrity of filter elements

A multi-machine testing and integrity technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as low testing efficiency and single-machine testing, so as to improve testing efficiency, ensure environmental requirements, The effect of easy reference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

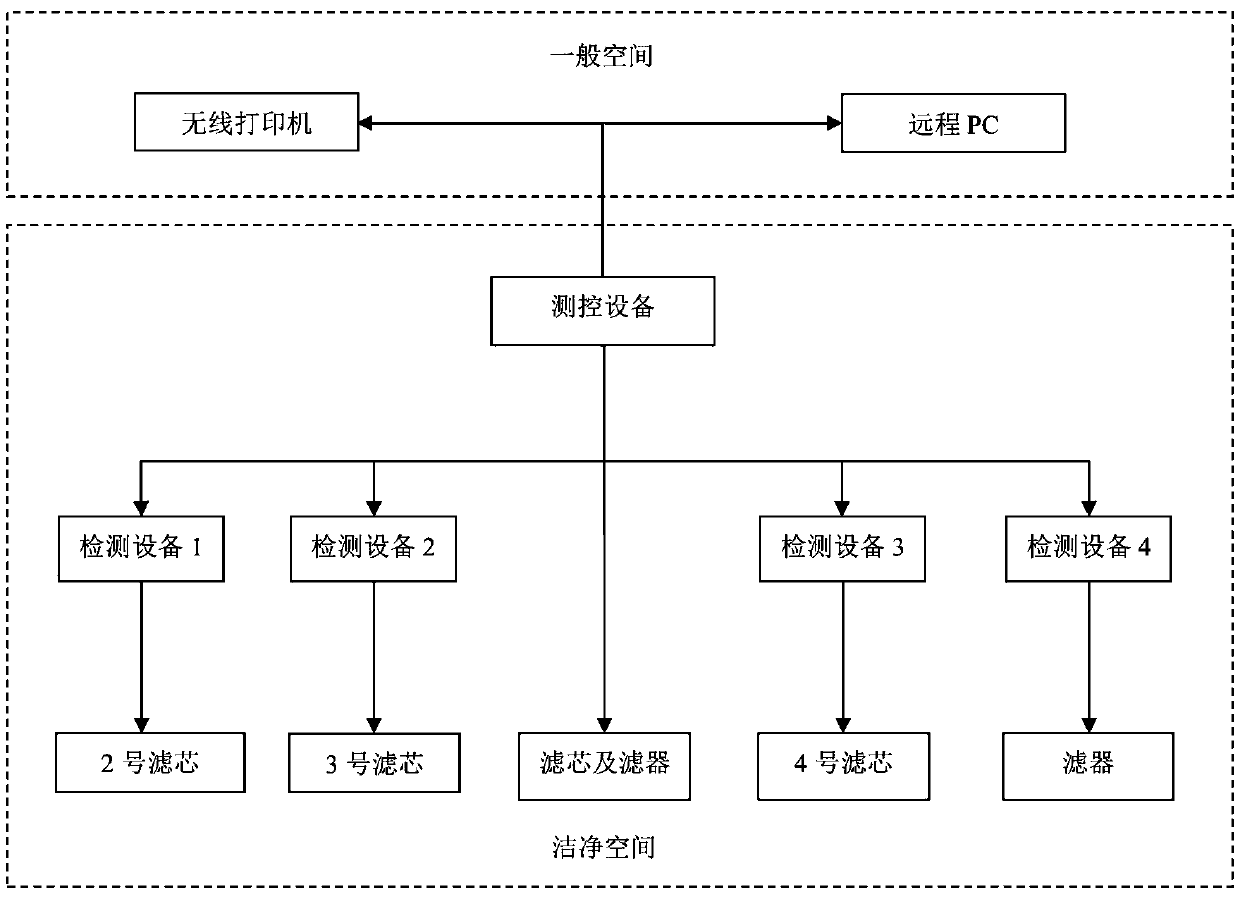

[0019] See Figure 1-3 , This implementation case, a fully automatic multi-machine test system for filter element integrity, including measurement and control equipment for testing and management work, connected with the measurement and control equipment to receive commands sent by the measurement and control equipment, complete the test work, and upload data to at least one of the measurement and control equipment Testing Equipment. The measurement and control equipment is connected with a remote PC.

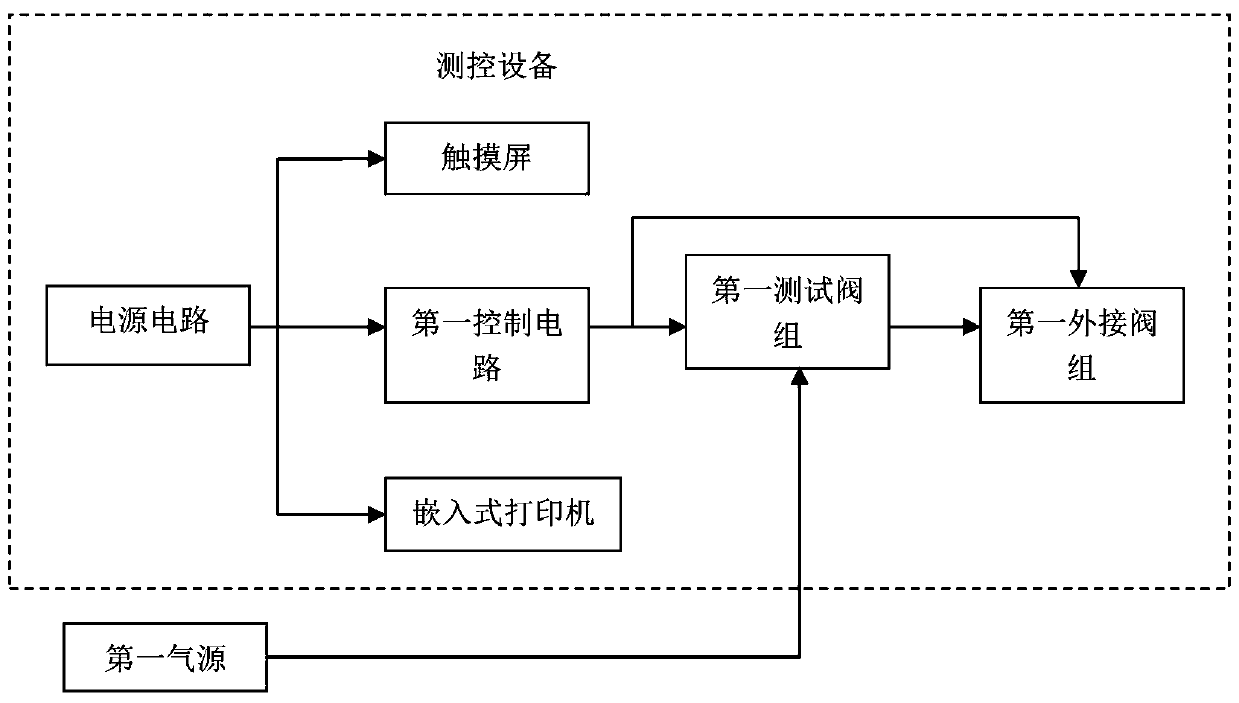

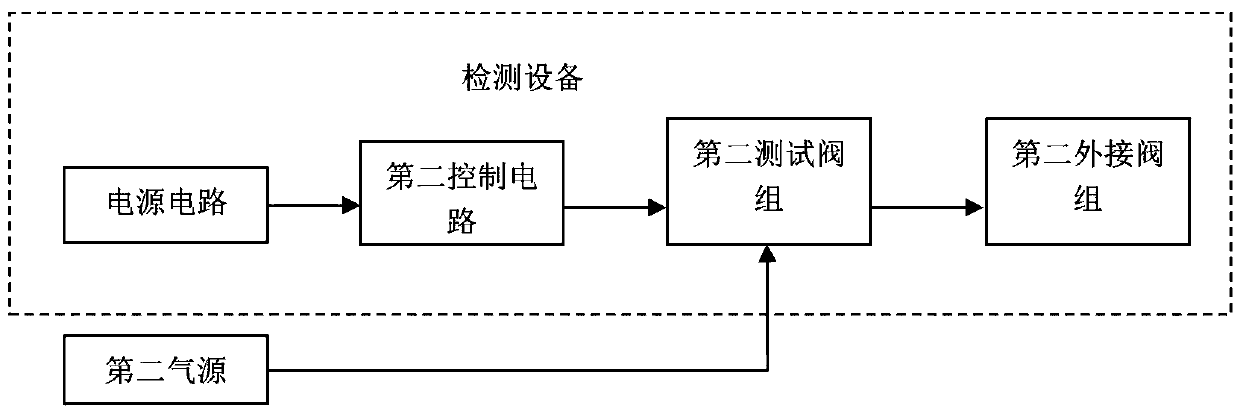

[0020] The measurement and control equipment includes a first control circuit, a first test valve group, a first external valve group, and a touch screen. The first test valve group is provided with a first gas source; each test device includes a second control circuit and a second test. The valve group and the second external valve group, and the second test valve group is connected with a corresponding second air source. Each testing device can be connected to a filter element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com