A soft-pack lithium battery trial production line in a glove box environment and its production process

A soft-pack lithium battery and glove box technology, which is applied in secondary battery manufacturing, electrolyte storage battery manufacturing, battery assembly machines, etc., can solve the problems of destroying the balance of water and oxygen content, low production efficiency, and no modular production line, etc., to achieve The effect of preventing the transmission of corrosive gas, reducing the length, and eliminating tiny gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

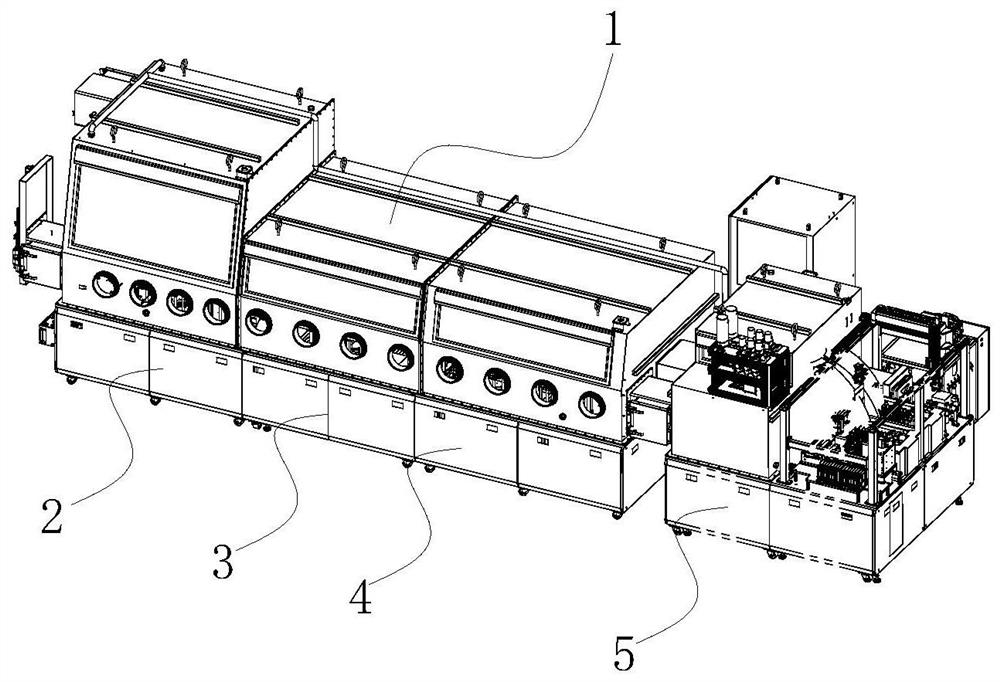

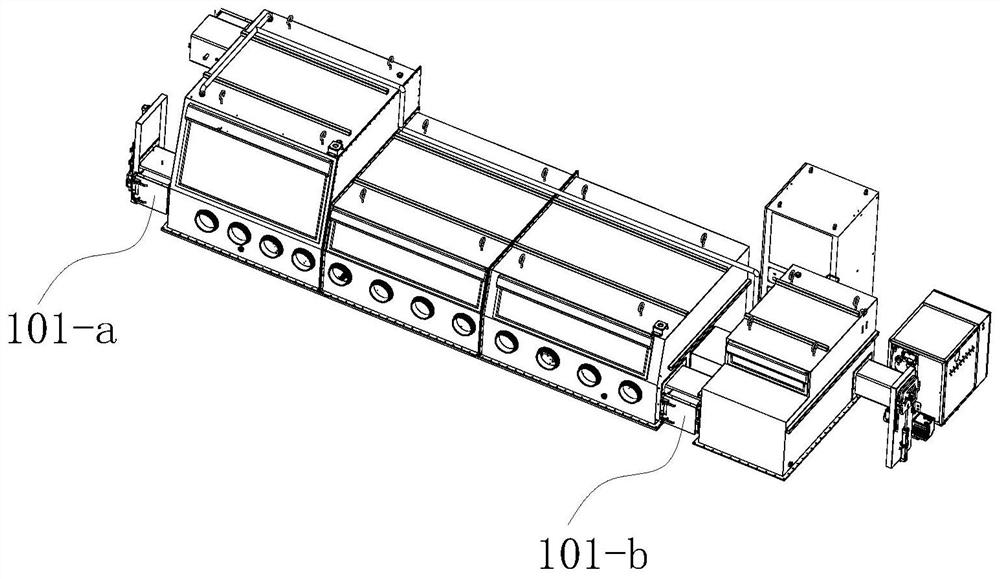

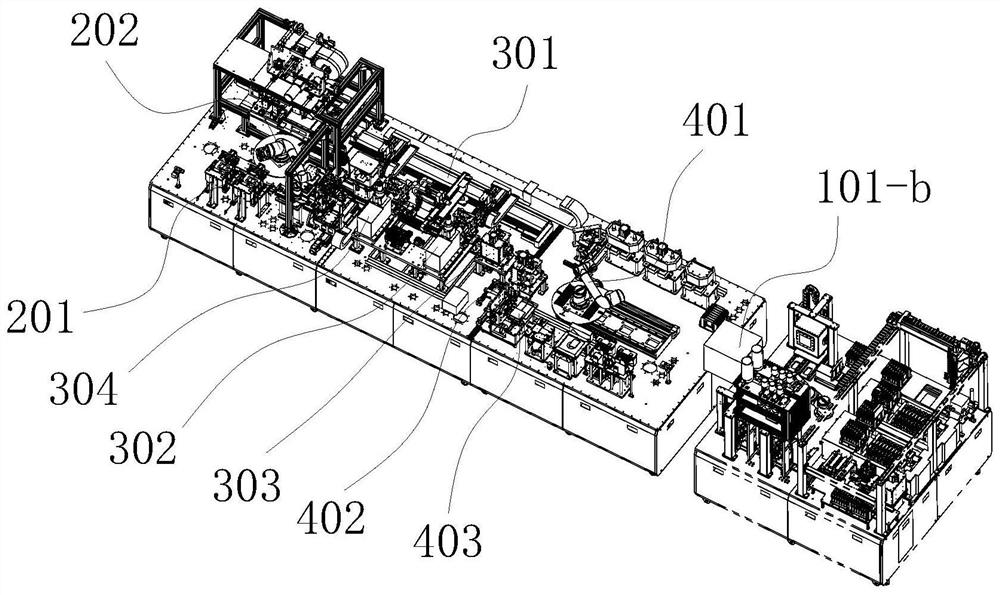

[0071] A soft-pack lithium battery trial production line under the environment of a glove box 1, which includes: a frame and a glove box 1, and a stacking device 2, a welding device 3, a heat sealing device 4, and a liquid injection-forming device 5 are arranged on the frame , wherein the heat-sealing device 4 and the liquid injection-formation device 5 are connected through a vacuum purification transition chamber 101-b, and the vacuum purification transition chamber 101-b is used to realize the connection between the lithium battery lithiation module and the assembly module and between the assembly module and the liquid injection module The connection between them, the transition chamber has a vacuum purification function to prevent the transmission of corrosive gas, and a material transition chamber 101-a is also provided in front of the lamination device 2. The stacking device 2 is used to laminate the battery pole pieces and the diaphragm to manufacture the battery core; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com