Coil shaping device and shaping method

A shaping device and coil technology, which is applied in coil manufacturing and other directions, can solve the problems of low yield rate, time-consuming and labor-intensive, difficult to achieve the outer contour size of the coil within the specification range, etc., and achieve the effect of improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

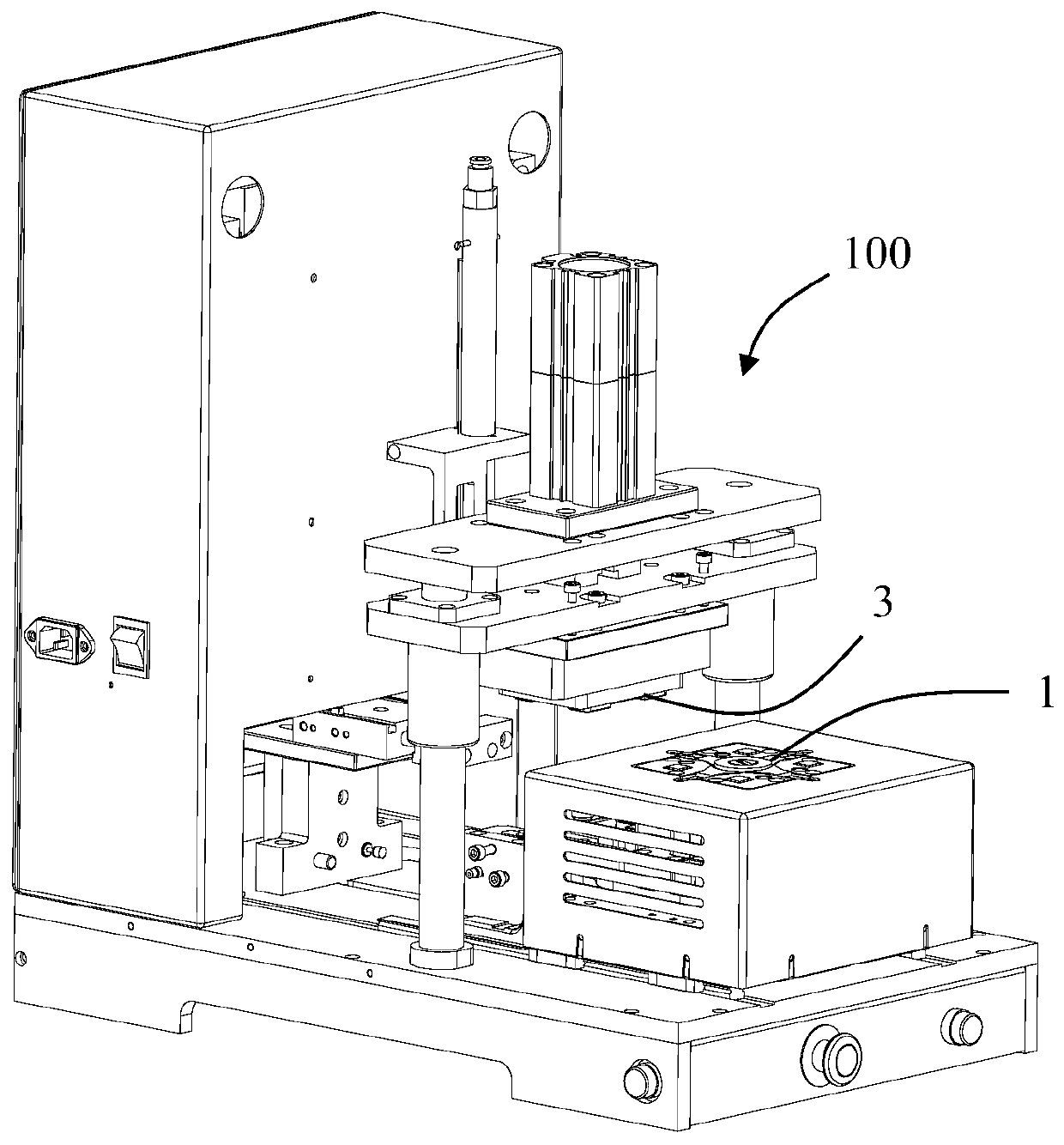

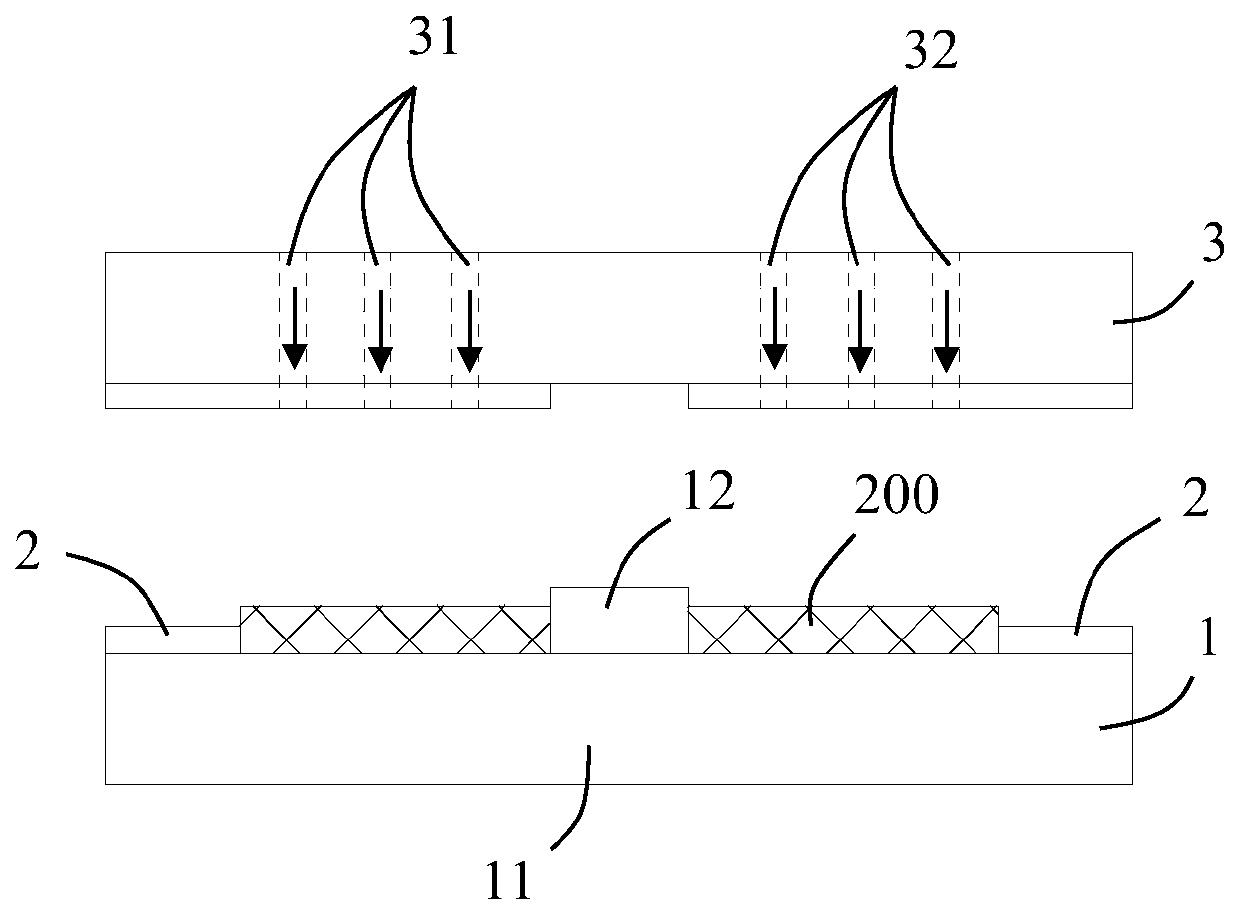

[0030] Please refer to Figure 1 to Figure 11 As shown, the present invention discloses a coil shaping device 100, which includes an installation part 1 for installing the coil to be shaped 200, a heating component (not shown) for softening the coil to be shaped 200, and a A shaping component 2 for shaping the softened coil 200 to be shaped and a cooling component (not shown) for cooling the shaped coil.

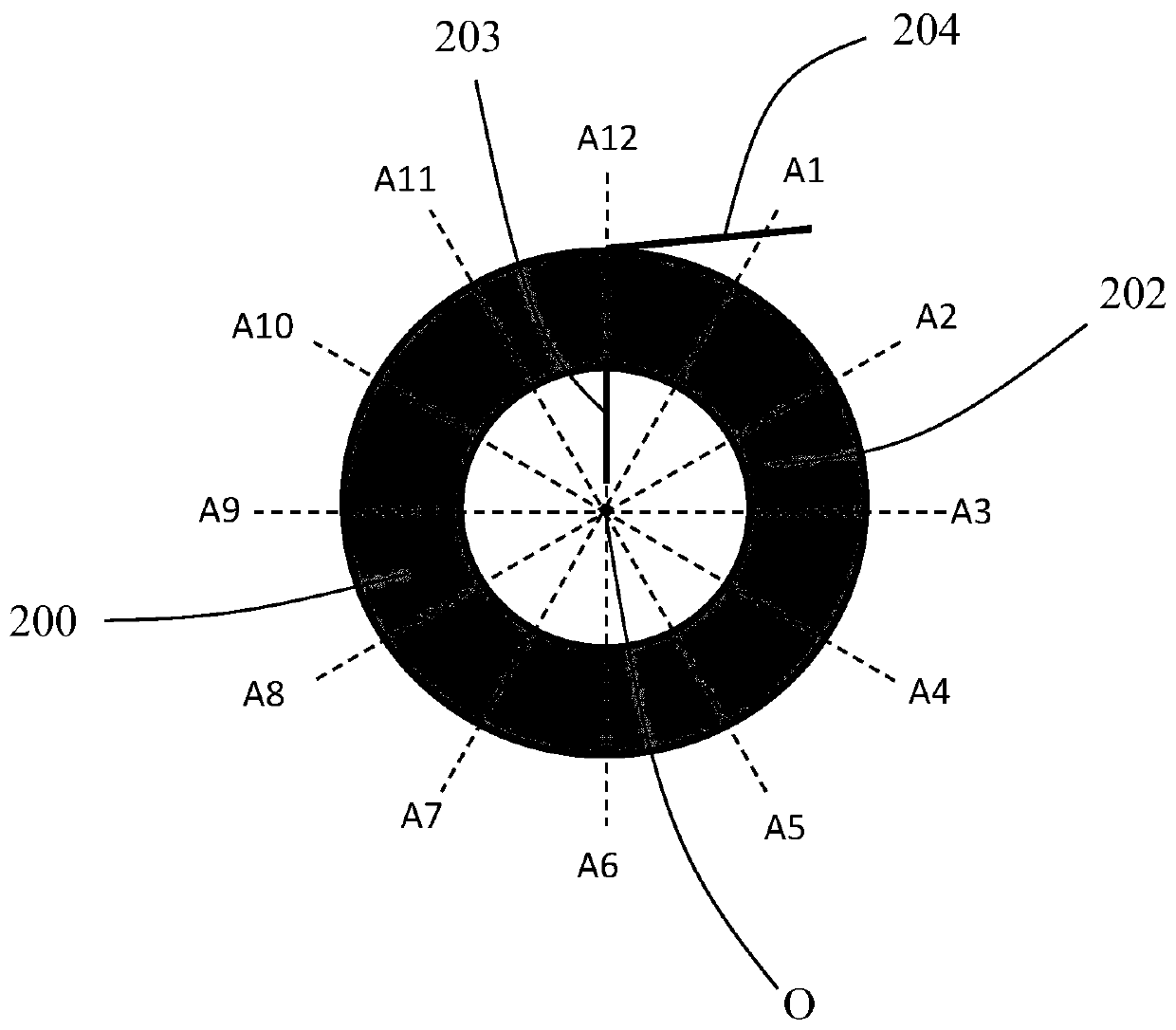

[0031] Please refer to figure 2 As shown, in one embodiment of the present invention, the to-be-shaped coil 200 is described as an example of a ring-shaped coil, wherein the ring-shaped coil includes a helical winding portion 202, from which the winding portion 202 A first wire 203 extending from the starting end of the winding portion 202 and a second wire 204 extending from the ending end of the winding portion 202 . The annular coil is provided with a center O and a number of measuring points evenly distributed on its outer contour. In the illustrated embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com