A high-voltage line inspection device

A technology for high-voltage lines and casings, applied in transportation and packaging, overhead line/cable equipment, motor vehicles, etc., can solve the problems of poor reliability, high labor intensity, low work efficiency and low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

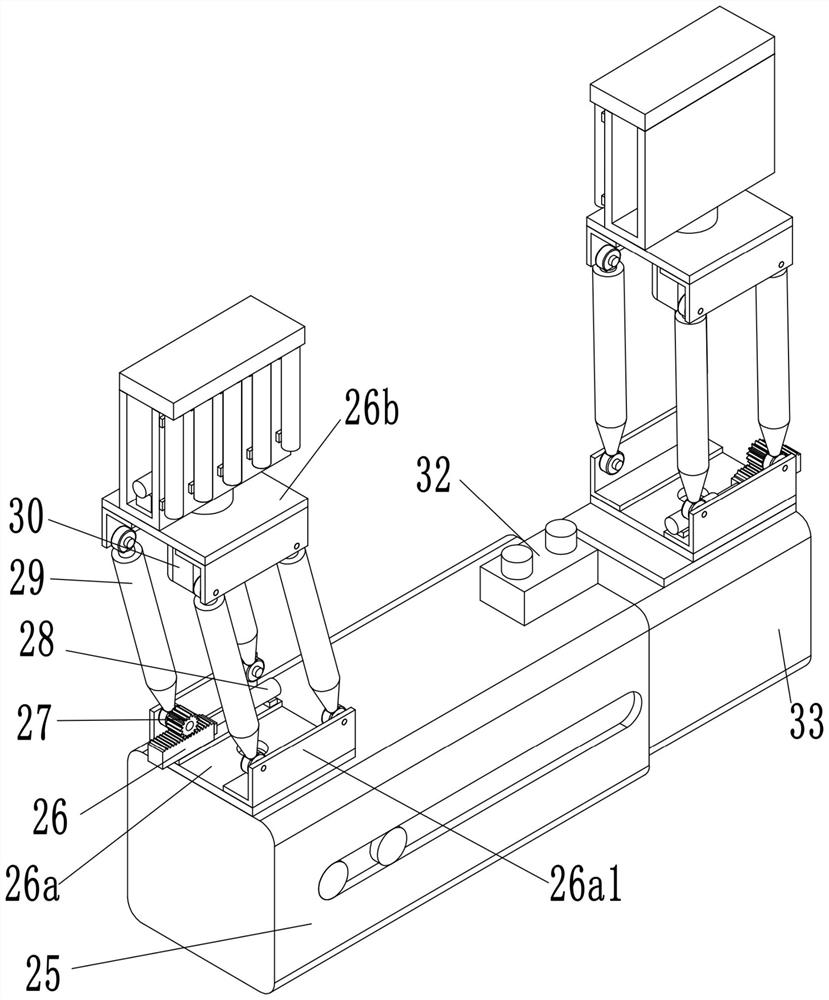

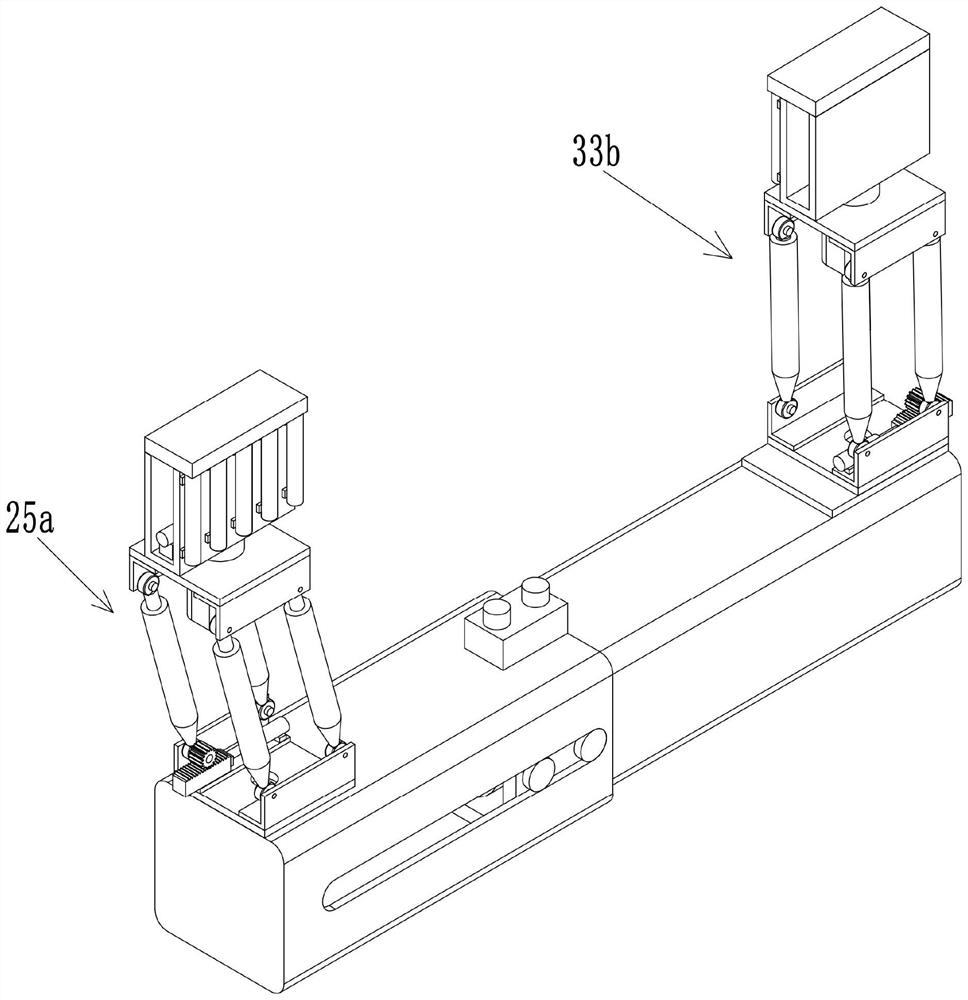

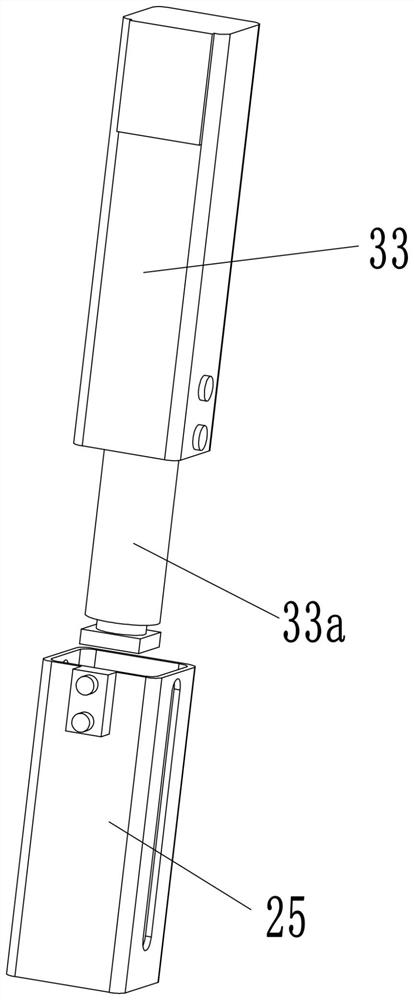

[0019] see Figure 1-7 As shown, a high-voltage line inspection device includes a first sleeve 25 with a square cross section, and a second sleeve 33 slidingly connected in the first sleeve 25, and the second sleeve 33 is provided with a telescopic end The fifth electric push rod 33a fixedly connected with the first sleeve 25; the first sleeve 25 is provided with a first lanyard assembly 25a, and the second sleeve 33 is provided with a second lanyard assembly 33b; A first camera 32 for collecting high voltage line video streams is provided between the first hanging rope assembly 25a and the second hanging rope assembly 33b on the first bushing.

[0020] The first lanyard assembly 25a and the second lanyard assembly 33b have the same structure and both include a lower deck 26a and an upper deck 26b, and two side plates 26a1 are arranged side by side along the length direction of the first sleeve 25 on the deck; Two sixth electric push rods 29 are hinged on the two side plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com