An Inner Helical Injection Vascular Robot Driven by External Magnetic Field

An internal spiral and external magnetic field technology, applied in the field of vascular robots, can solve the problems of slow progress, unstable movement process, and insufficient power of micro robots, and achieve the effect of improving flexibility, increasing movement speed, and realizing bidirectional movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

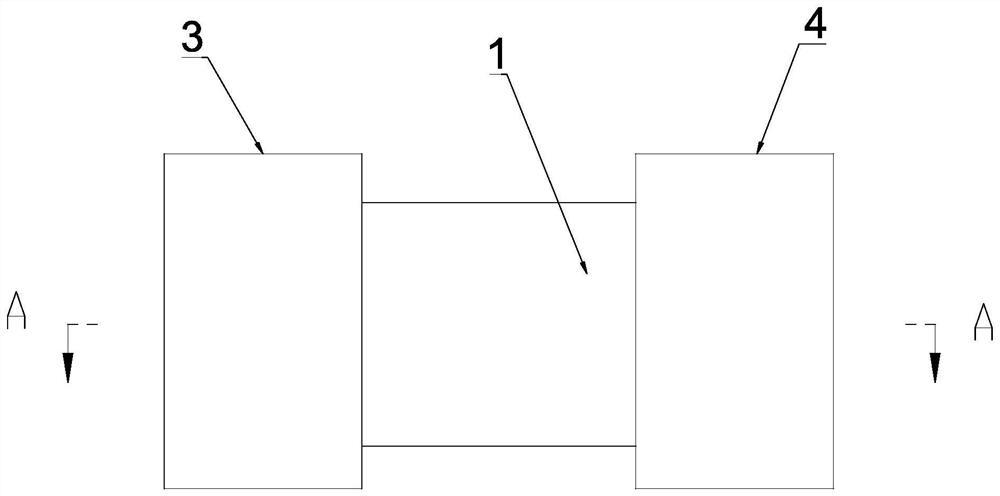

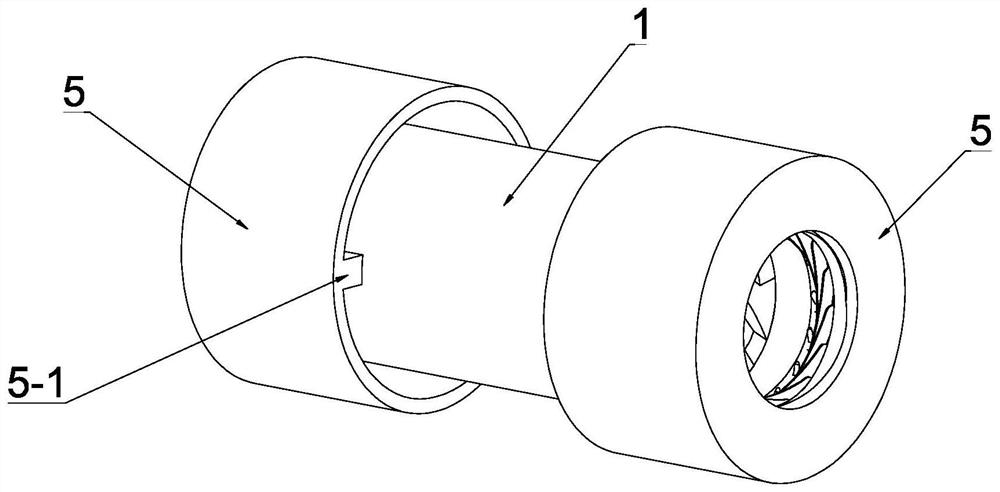

[0040] see Figure 1-Figure 4 , the present embodiment discloses an internal helical injection vascular robot driven by an external magnetic field, which includes a tube body 1, an annular permanent magnet 2 arranged on the tube body 1, and an annular permanent magnet 2 arranged at both ends of the tube body 1 for changing the tube body. A diameter-reducing device with openings at both ends of the body 1, and a spiral groove 1-1 is provided on the inner wall of the pipe body 1.

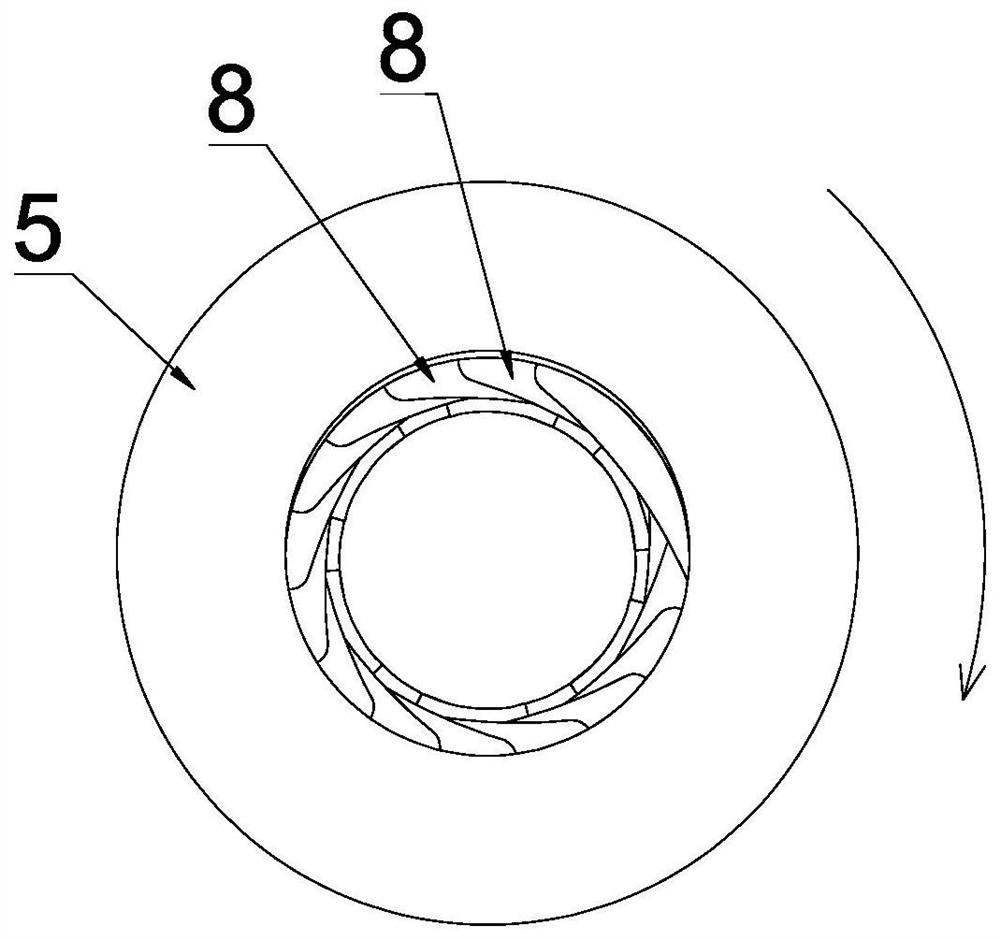

[0041] see Figure 1-Figure 6 , the diameter reducing device includes a left end diameter reducing device 3 located at the left end of the pipe body 1 and a right end diameter reducing device 4 located at the right end of the pipe body, the left end diameter reducing device 3 and the right end diameter reducing device 4 both include The connecting sleeve 5 at the end of the body 1, the fixed adjustment member 6 fixedly connected to the end of the pipe body 1 and arranged coaxially with the pipe body ...

Embodiment 2

[0061] see Figure 14 , the other structures in this embodiment are the same as in Embodiment 1, the difference is that the sliding adjustment groove 8-2 is an arc-shaped sliding adjustment groove, and the arc-shaped sliding adjustment groove is eccentrically arranged on the fixed adjustment member 6 , wherein, the rotation direction of the arc-shaped sliding adjustment groove in the left-end diameter reducing device 3 is opposite to the rotation direction of the arc-shaped sliding adjustment groove in the right-end diameter reducing device 4 . By setting the above-mentioned structure, the sliding adjustment groove 8-2 is arranged in an arc shape, and is eccentrically arranged on the fixed adjustment member 6, so that the stroke of the adjustment rod 8-4 in the sliding adjustment groove 8-2 can be improved, thereby improving the height of the adjustment blade. The swing angle of 8-1 can further increase the variation interval of the openings at both ends of the pipe body 1. By...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com