Fixer for air duct machine motor

A technology of electromechanical motors and fasteners, applied in electromechanical devices, wind power generation, pipeline layout, etc., can solve the problems of friction noise, the lack of buffering and shock absorption of the fasteners, and the small scope of application of the fasteners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

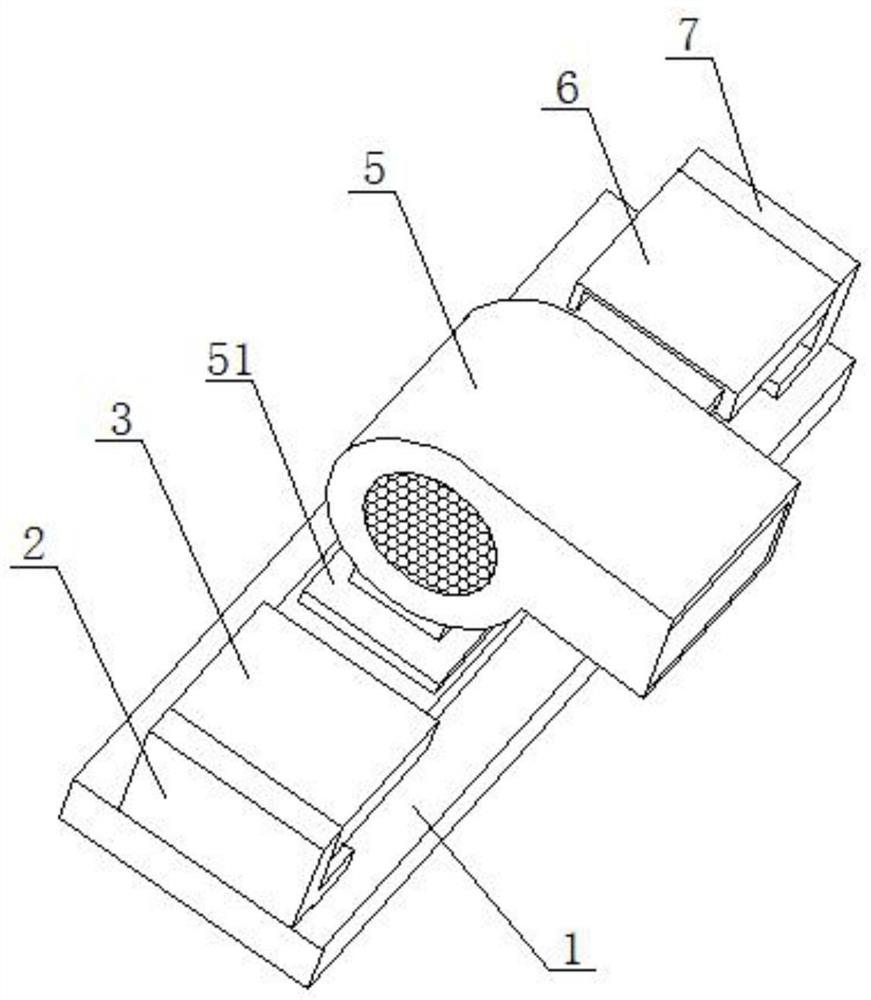

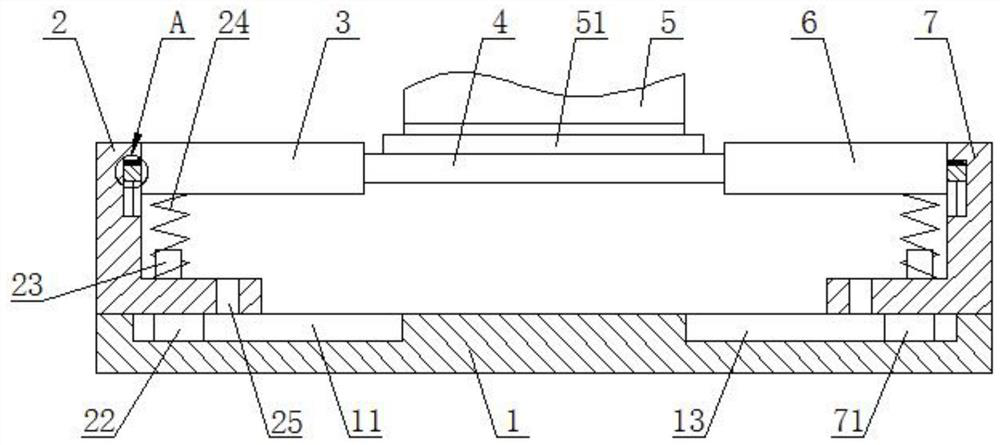

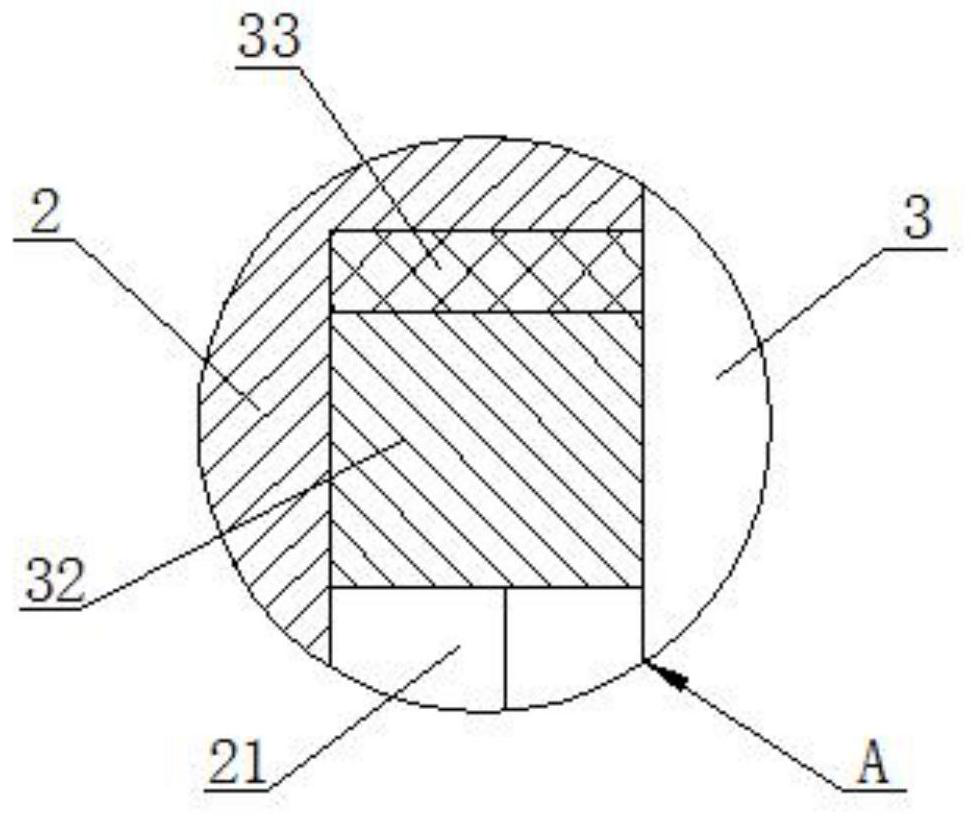

[0035] see Figure 1-5 , a fixture for the motor of an air duct machine, including a base plate 1, please refer to Figure 1-5 The upper surface of the base plate 1 is provided with a left chute 11, and the surface of the base plate 1 is provided with symmetrical threaded holes 12, the threaded holes 12 are threaded to fix the fastening bolts, the upper surface of the base plate 1 is provided with a right chute 13, the base plate The upper end of 1 is slidably connected with a left support plate 2. The shape of the left support plate 2 is L-shaped, and the support stability is strong. The left support plate 2 is used to fix the position of the left fixed plate 3. The surface of the left support plate 2 is provided with symmetrical Mounting holes 25, the mounting holes 25 are connected to the corresponding threaded holes 12 by bolts, and are used to fix the position of the left support plate 2 on the base plate 1, the upper end of the left support plate 2 is slidably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com