Clamping means assembly for a machine tool, and machine tool comprising the clamping means assembly

A fixture and component technology, applied in the direction of metal processing mechanical parts, clamping, manufacturing tools, etc., can solve the problems of high cost and no equipment, and achieve high feed speed, improved processing effect, and more cost-effective effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

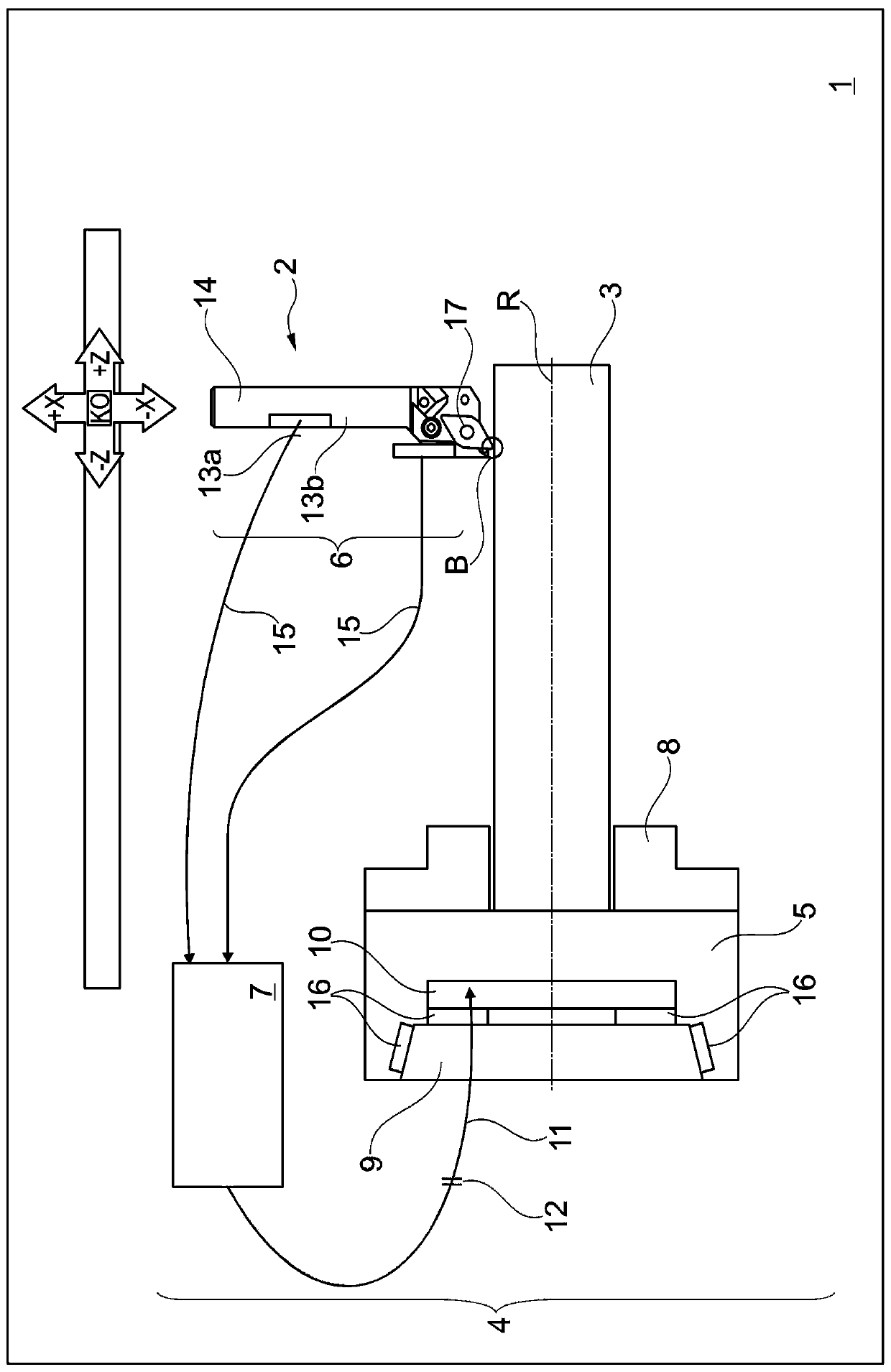

[0029] figure 1 A machine tool 1 with a tool 2 for machining a workpiece 3 is shown as an exemplary embodiment of the invention in a very schematic illustration. Conceptually, the workpiece 3 is rotated during machining about an axis of rotation R, which extends parallel to the Z direction in the coordinate system KO of the machine tool 1 . In the side view shown, the X direction runs perpendicularly to the Z direction in the coordinate system KO. In particular the X-Z plane is shown.

[0030] The tool 2 can be designed, for example, as a boring tool, milling tool, turning tool or broaching tool. In the present embodiment, the tool 2 is realized as a turning tool. The knife 2 has a knife holder 14 with a shank and a head, wherein an indexable blade is arranged on the head as a cutting body 17 .

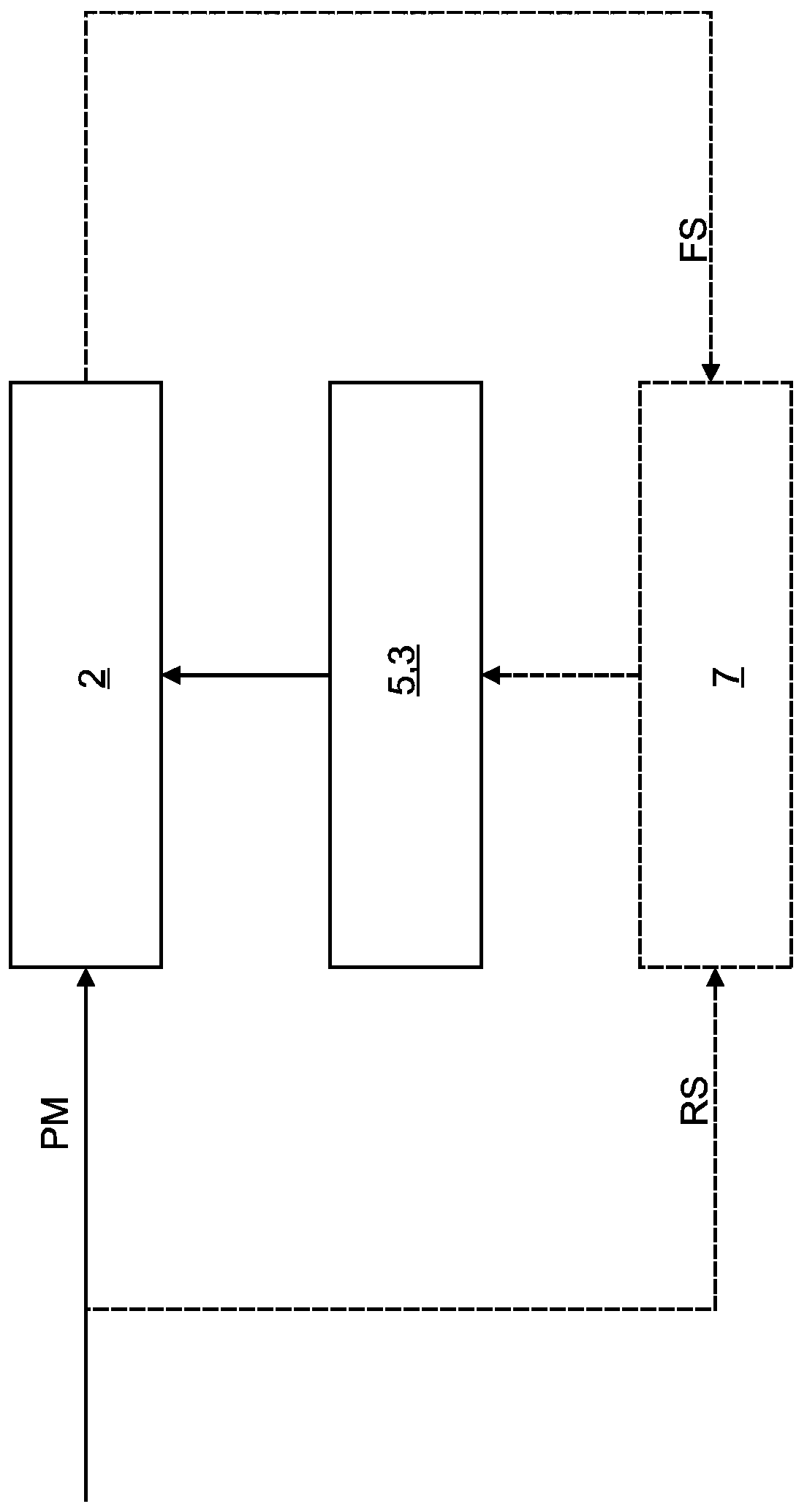

[0031] The machine tool 1 has a gripper assembly 4 constructed from a sensor assembly 6 , a gripper 5 and a control device 7 . The clamping device 5 has a clamping chuck, in part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com