Dust collector and collecting method of golden paper burning barrel

A technology of dust collector and golden bucket, applied in chemical instruments and methods, separation methods, household appliances, etc., can solve problems such as polluting the environment and destroying environmental sanitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

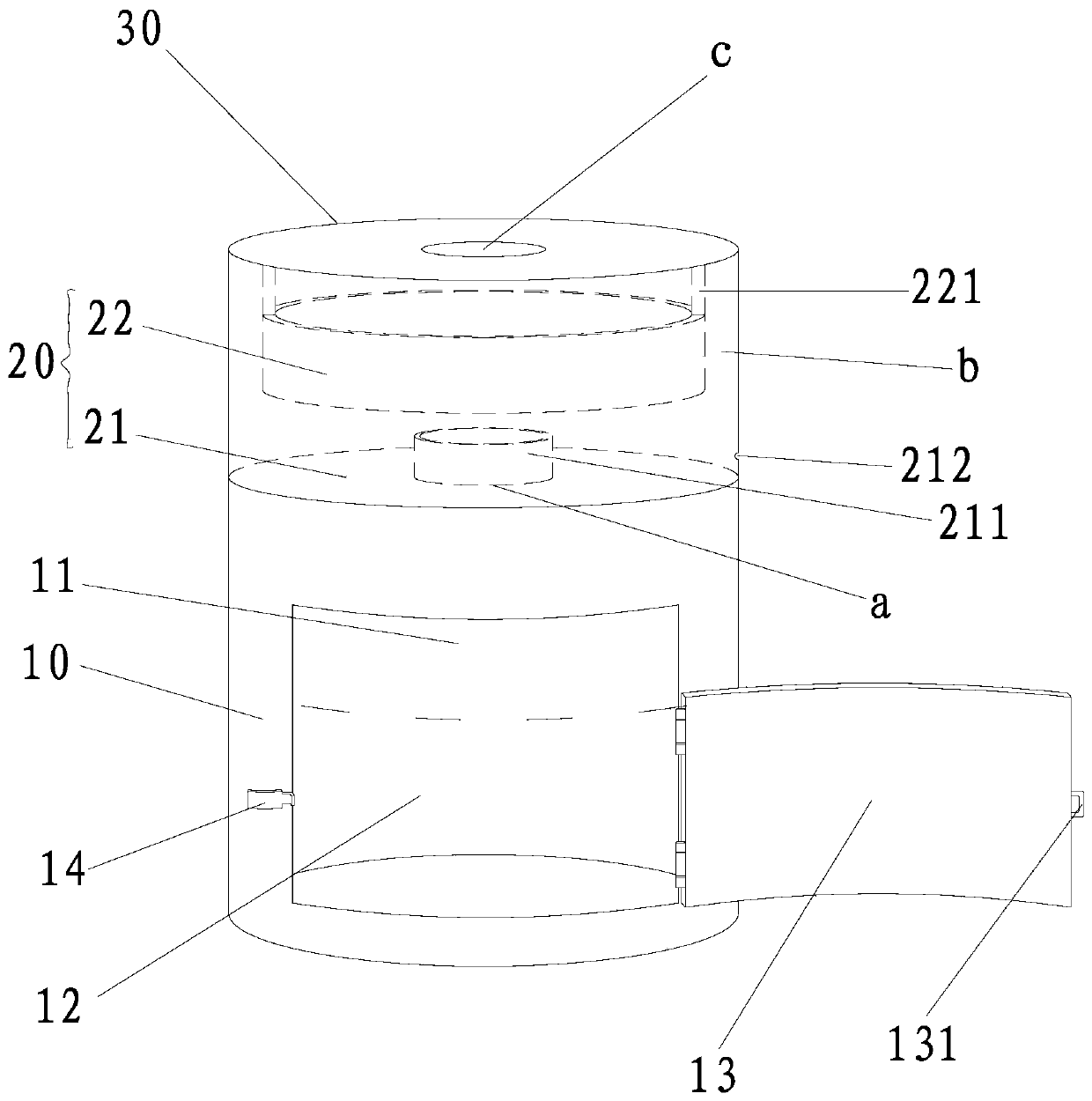

Image

Examples

Embodiment 2

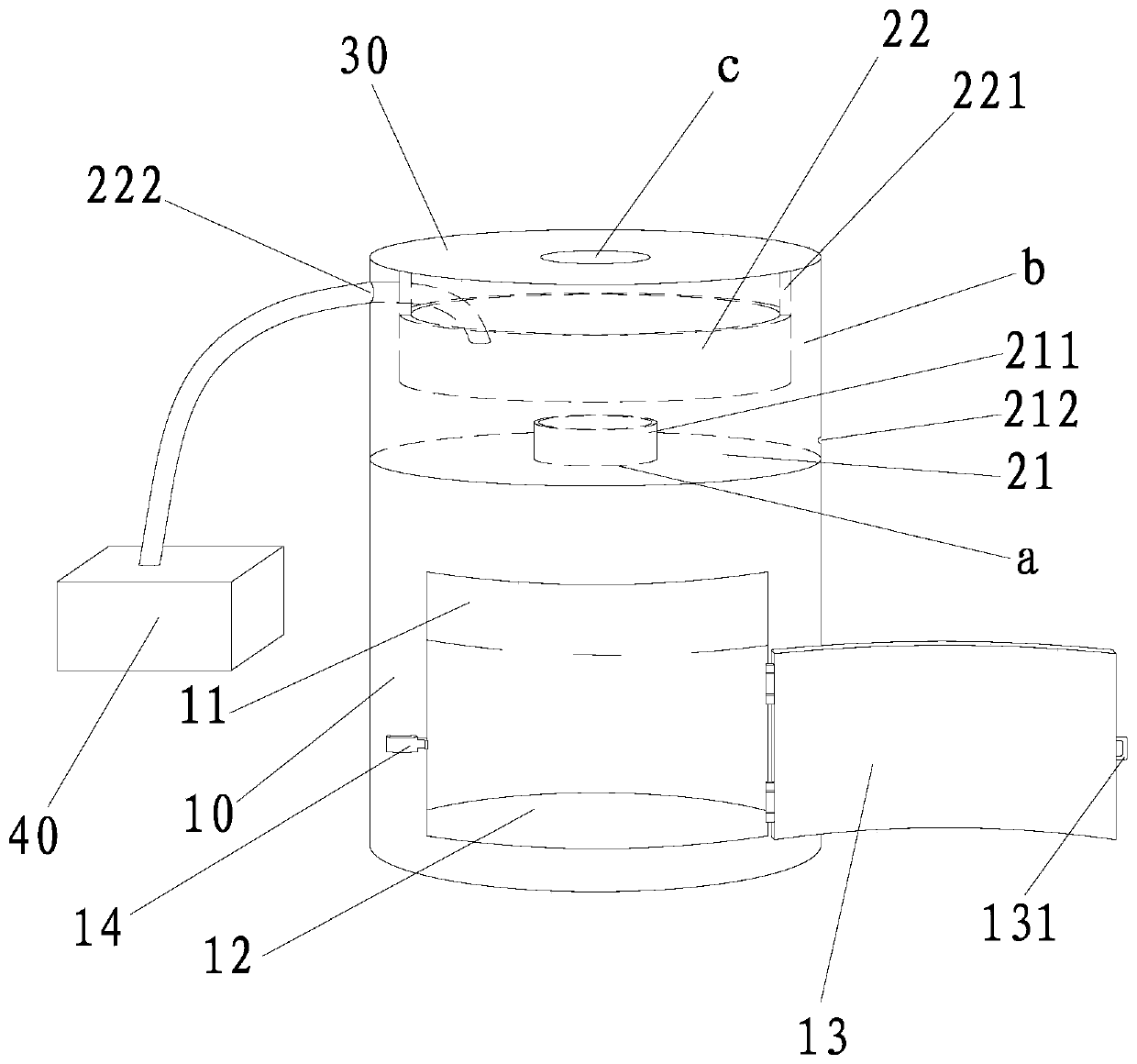

[0055] like figure 2 As shown, the difference between the dust collector of this embodiment and the dust collector of Embodiment 1 is that the dust collector also includes a water pump 40, a control chip and a water level monitoring device, and the collecting part 20 corresponds to the secondary collecting part 22. The position is provided with a liquid inlet 222, the liquid outlet of the water pump 40 is connected with the liquid inlet 222 through a water pipe, one end of the water pipe is connected with the liquid outlet of the water pump 40, and the other end of the water pipe is placed in the secondary collection part 22, and the water level is monitored. The device is located in the secondary collection part 22, and the water pump 40 and the water level monitoring device are respectively connected to the control chip through a wireless connection; by setting the water pump 40, the control chip and the water level monitoring device, the dust collector can automatically add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com