Implementing device and method used for PPR pipeline hot melt connection

A hot-melt and pipeline technology, which is applied to the implementation device and field of PPR pipeline hot-melt connection, can solve the problems of time-consuming and labor-consuming, affecting the quality of pipeline connection, etc., and achieve shortened construction period, good quality of hot-melt connection, and saving human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

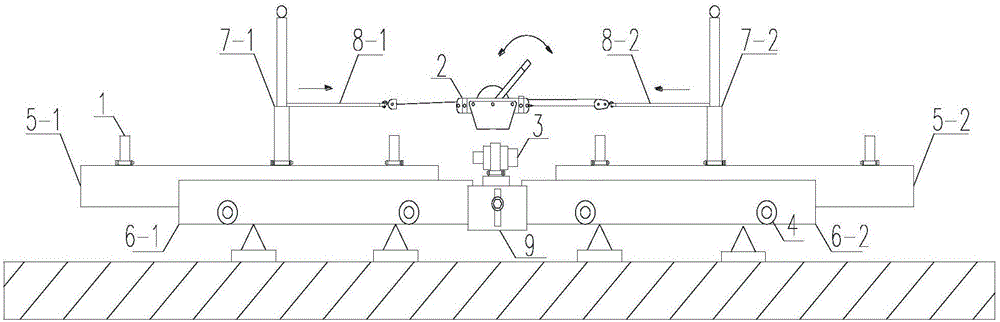

[0023] PPR pipe has good corrosion resistance, no scale, no bacteria, non-toxic and good hygienic performance, in order to solve the technical problems in the existing technology, such as figure 1 As shown, the present invention discloses a labor-saving device and method for connecting PPR pipes and pipe fittings. The pulling force generated by the tensioner is used as the power, and the semicircular steel pipe fixing the pipe moves along the direction of the force, so that the heat-fused Pipes and fittings are quickly; straight to the specified depth without rotation.

[0024] The specific devices are as follows:

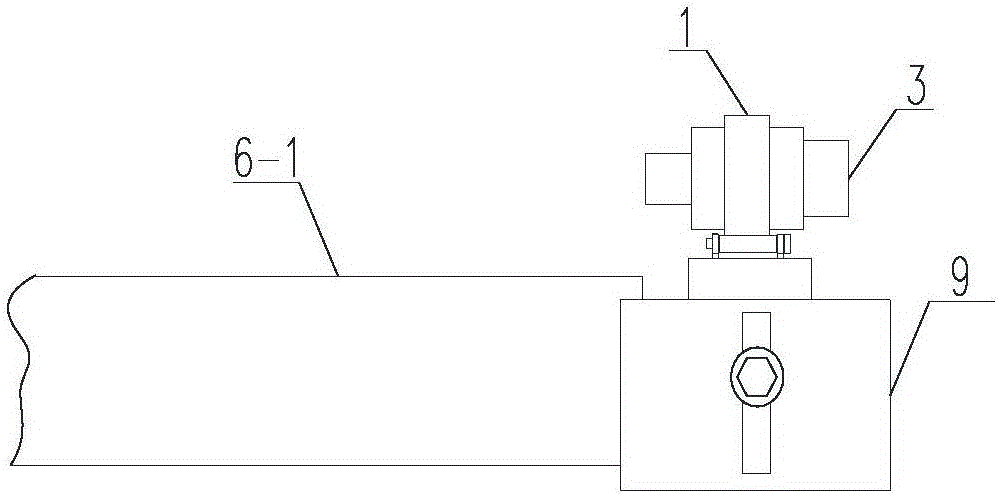

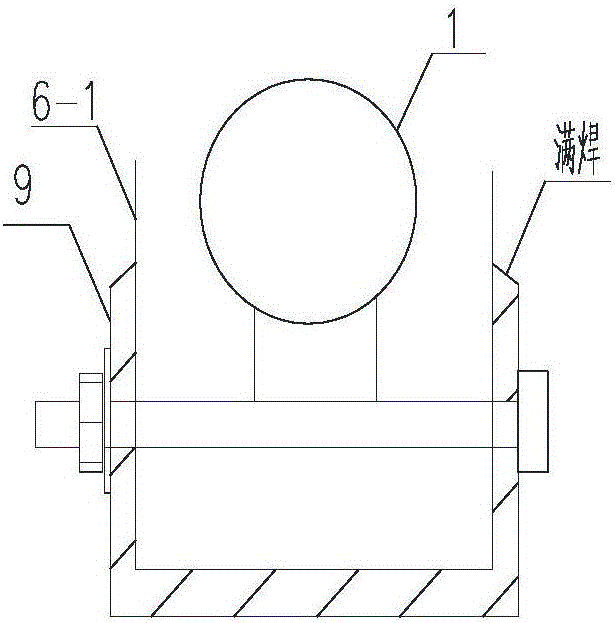

[0025] Such as Figure 1-3 As shown, a kind of implement device that is used for PPR pipe hot-melt connection, comprises channel steel 9, respectively connects a channel steel 6-1, channel steel 6-2 at the two ends of described channel steel 9, in described A fixed buckle 1 is fixed on the channel steel 9, and the described fixed buckle 1 is used for fixing the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com