Process structure for draining remaining stored water in electrolytic cell or electrolytic electrode assembly in water electrolysis device

A technology of electrolytic electrodes and electrode assemblies, which is applied in the field of electrolyzed water, and can solve problems such as poor quality, poor quality of electrolyzed water, and poor water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

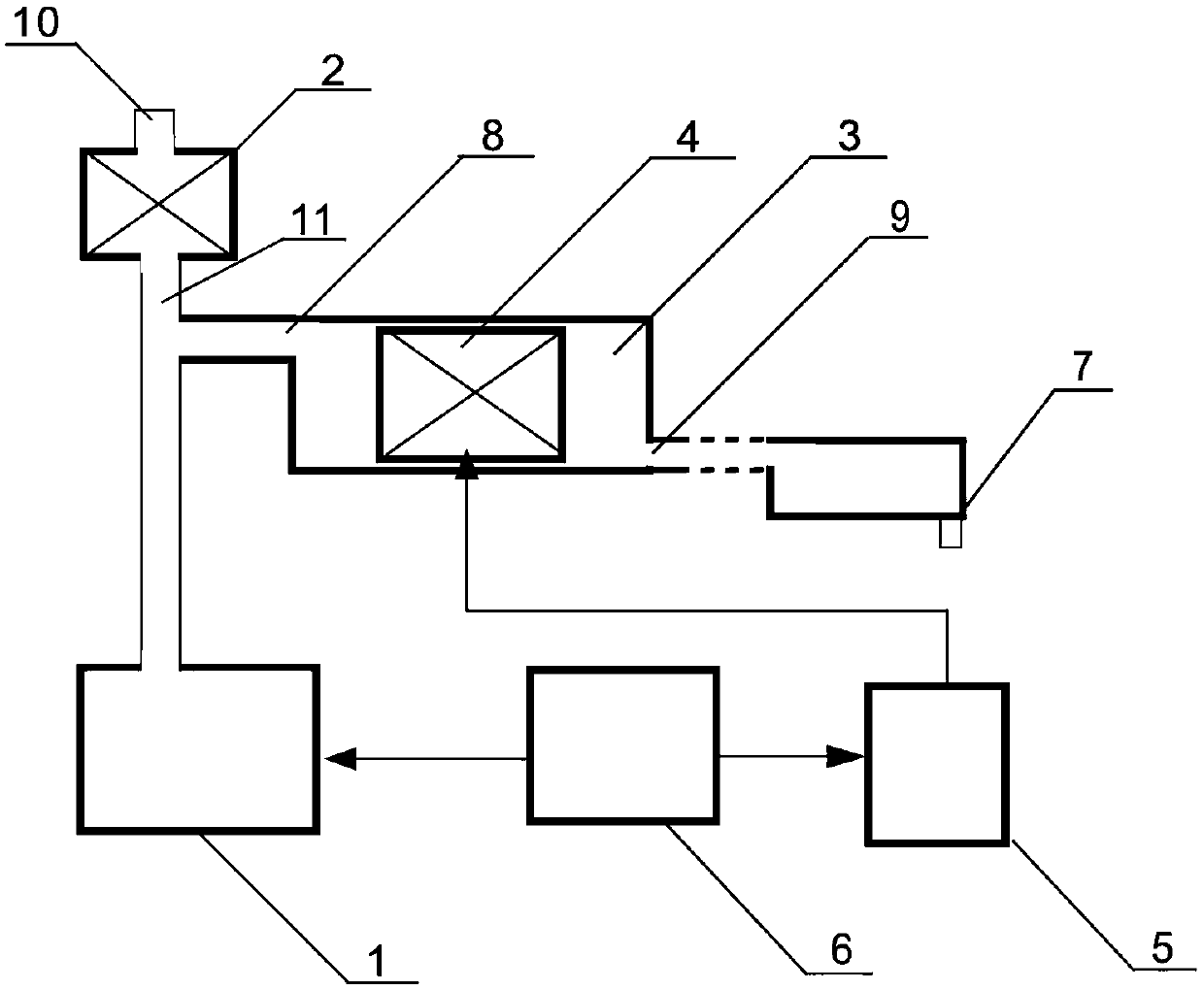

[0010] Such as figure 1 The process structure for removing the remaining water stored in the electrolytic cell or the electrolytic electrode assembly in the electrolytic water device of the present invention is shown, including a raw water supply part 1, an electrolytic cell 3, an electrolytic electrode assembly 4 installed in the electrolytic cell, a ventilation part 2, and an electrolytic power supply 5. Control component 6, device electrolyzed water output port 7; the electrolyzer 3 has a water inlet 8 and a water outlet 9, the electrolyzer water outlet 9 can discharge the water in the electrolysis electrode assembly 4, and the electrolyzer water outlet 9 is more electrolyzed than the device. The horizontal position of the water outlet 7 is high, so that the water in the electrolytic cell 3 may be naturally removed from the water outlet 9; The air outlet 11; the air-permeable part 2 is a one-way air-permeable part 2, and when the air pressure or water pressure of the air ou...

Embodiment 2

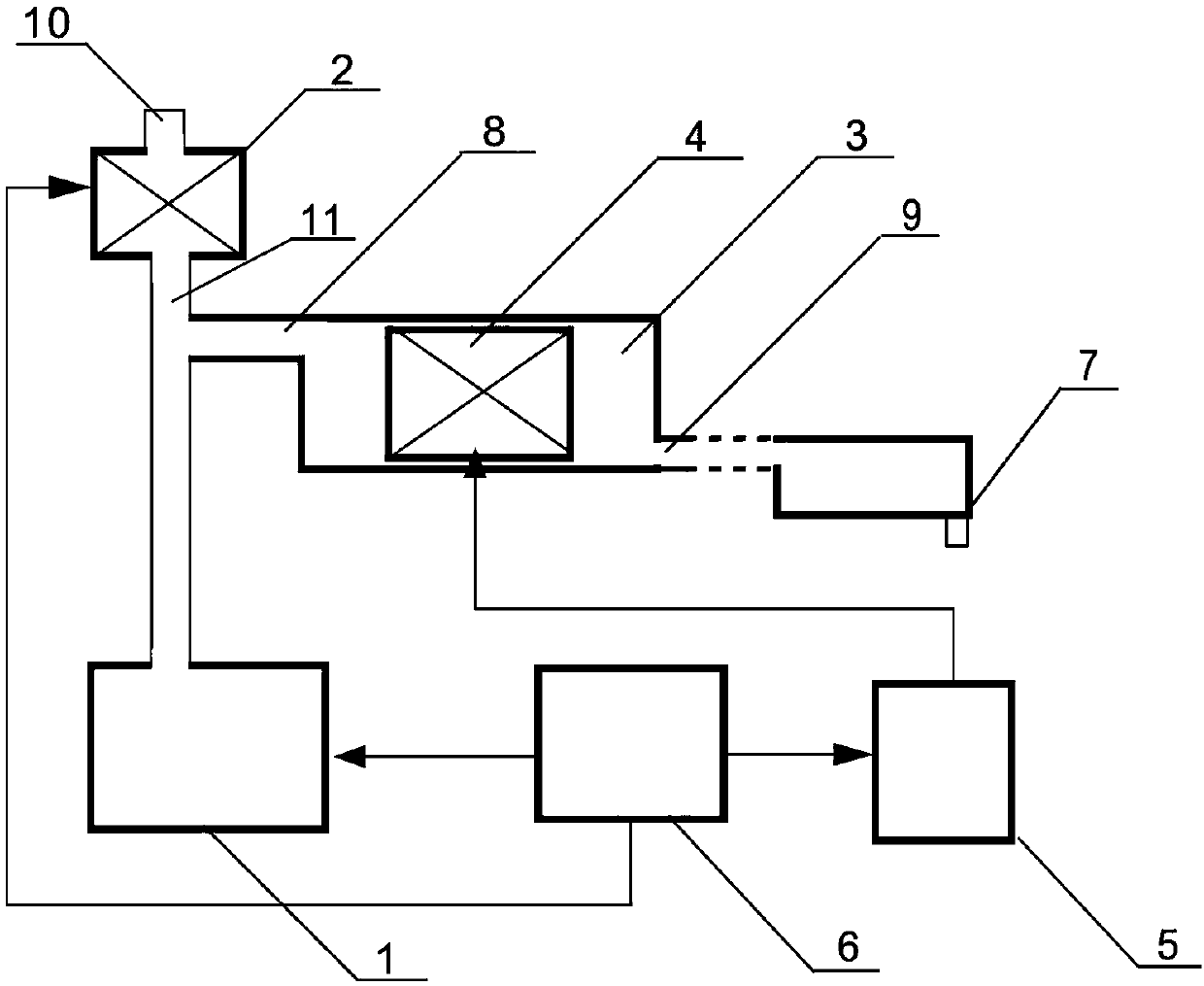

[0013] Such as figure 2 The process structure for removing the remaining water stored in the electrolytic cell or the electrolytic electrode assembly in the electrolytic water device of the present invention includes a raw water supply part 1, an electrolytic cell 3, an electrolytic electrode assembly 4 installed in the electrolytic cell, a ventilation part 2, and an electrolytic power supply 5. Control component 6, device electrolyzed water output port 7; the electrolyzer has a water inlet 8 and a water outlet 9, the electrolyzer water outlet 9 can discharge the water in the electrolysis electrode assembly 4, and the electrolyzer water outlet 9 is more than the device electrolyzed water The horizontal position of the output port 7 is high, so that the water in the electrolytic cell 3 may be naturally discharged from the water outlet 9; Air outlet 11, described ventilation part 2 is controlled one-way ventilation part 2; Described controlled one-way ventilation part 2 is an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com