Construction method for assembly type large-span wood beam string structure fixed pot type rubber support joint

A technology of rubber bearing and construction method, applied in the direction of building structure and construction, can solve the problems of large force at the bearing node and complex node structure, saving construction period, improving construction efficiency, strong application prospect and economical effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

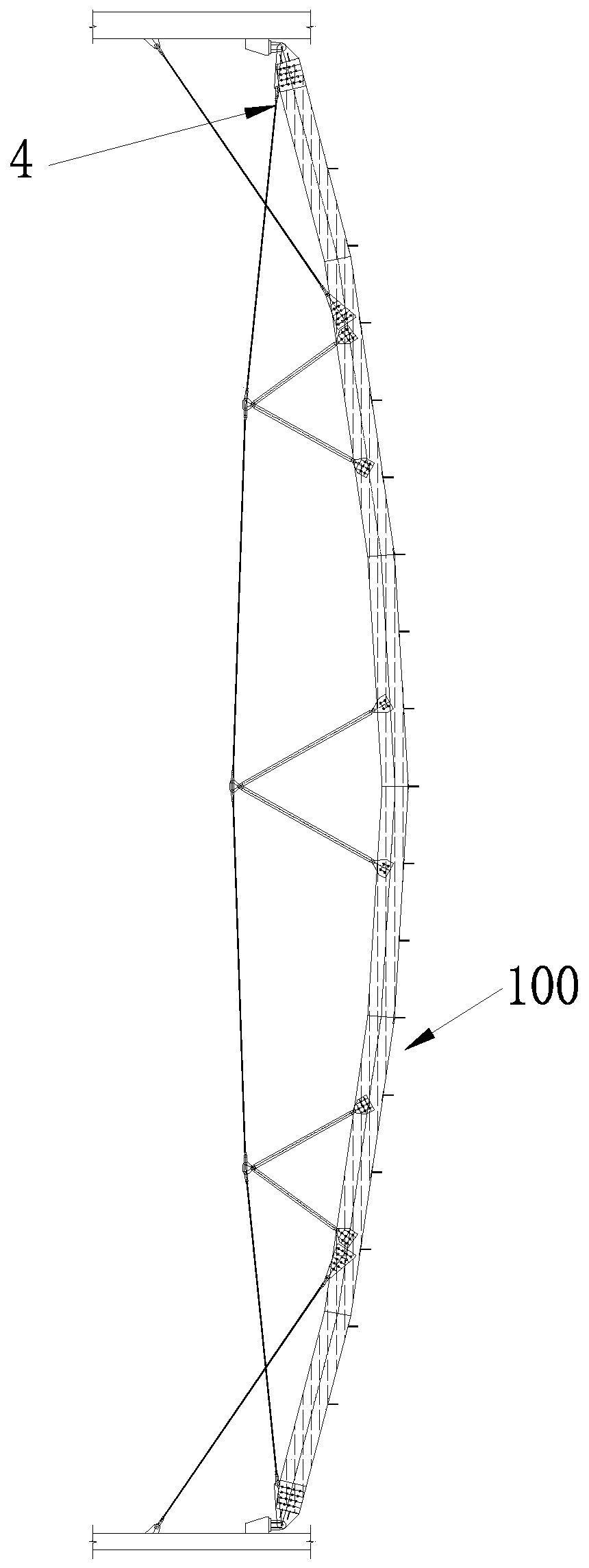

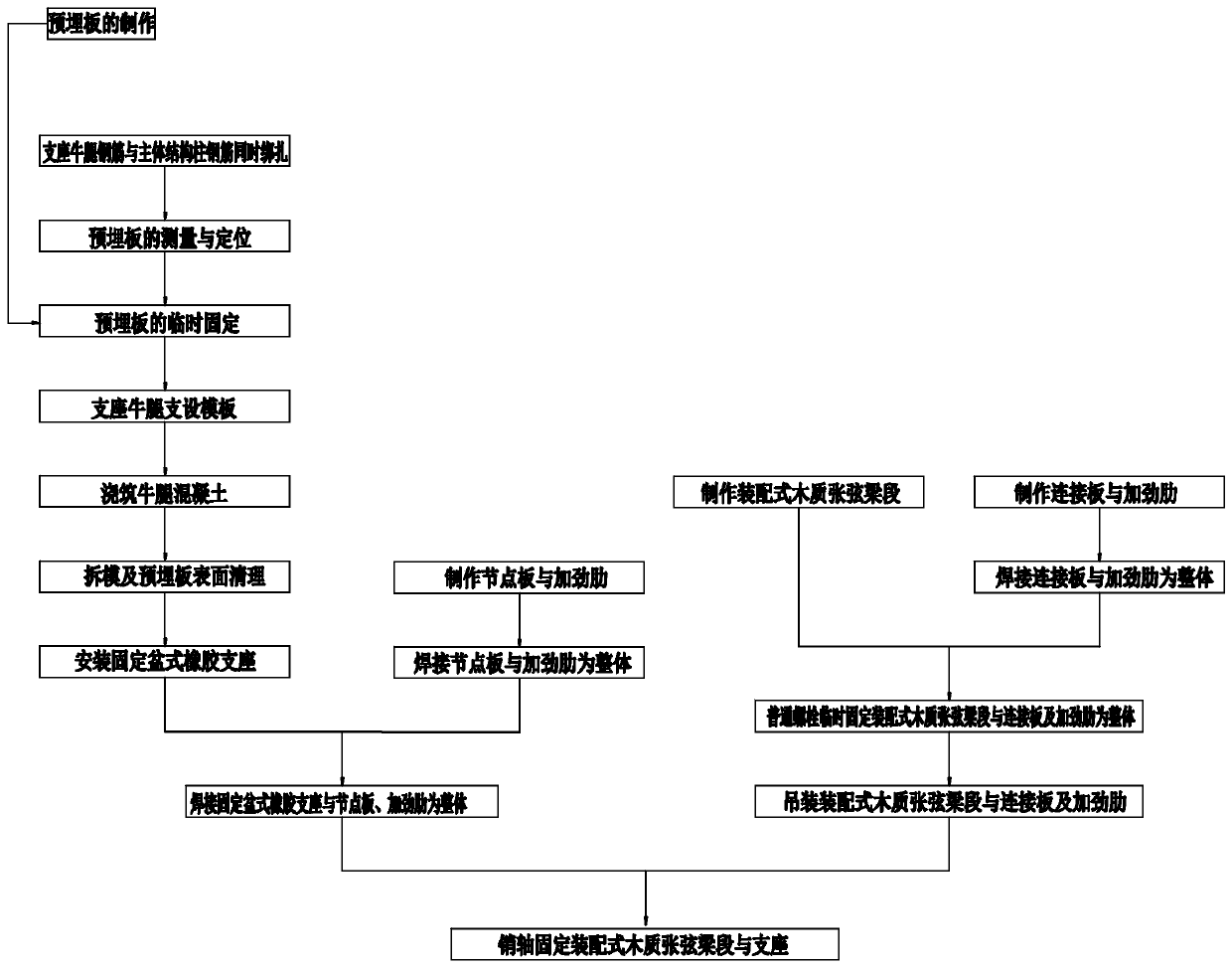

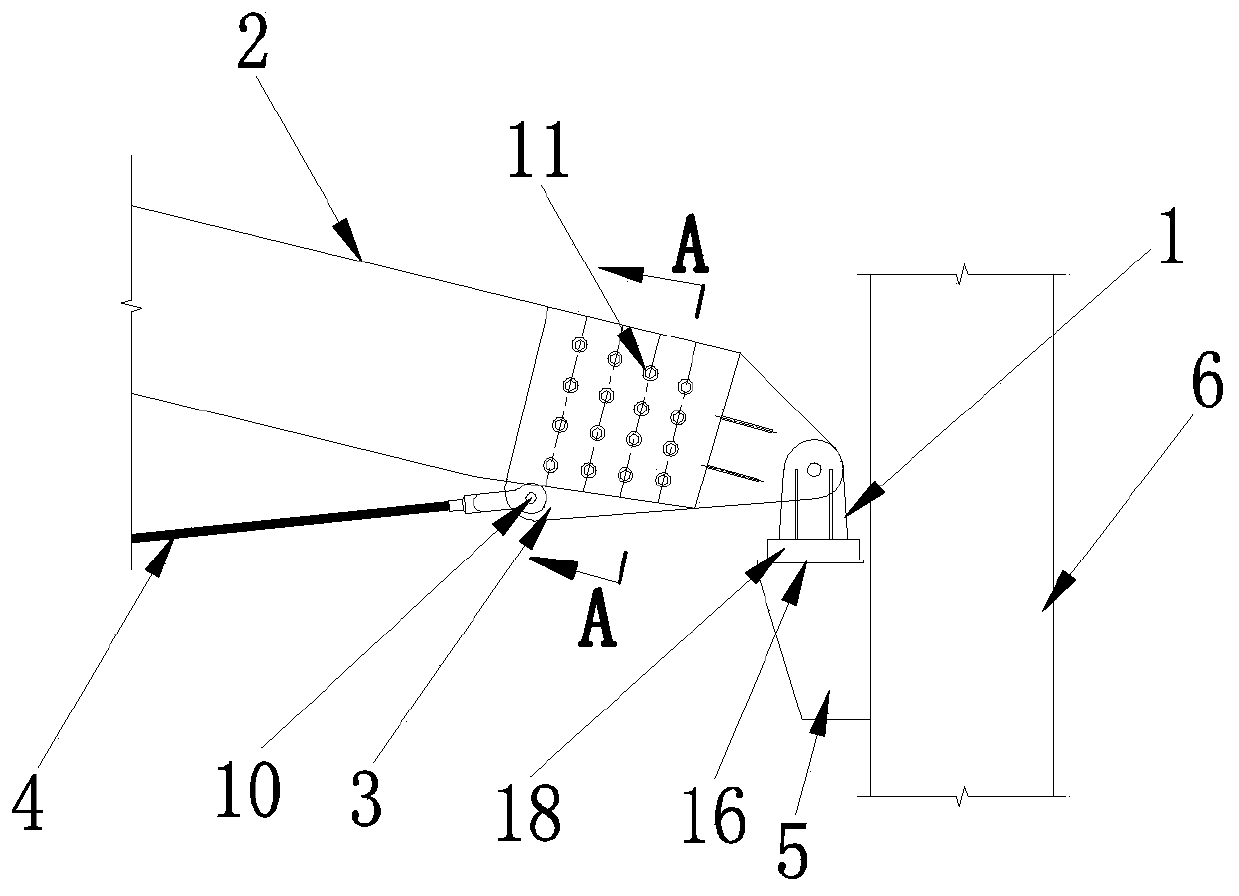

[0037] Example: such as figure 1 , as shown in 3-10, an assembled large-span wooden string beam structure fixed pot-type rubber bearing node, including a corbel 5 fixed on a concrete column 6, and a pre-embedded plate 16 is set on the corbel 5; pre-embedded The plate 16 is equipped with a fixed basin-type rubber bearing 18, and the fixed basin-type rubber bearing 18 is connected with a support seat 1, and the support seat 1 is rotationally connected with the connecting plate 3 through the support pin shaft 7; wherein, the corbel 5 is a steel bar Concrete structure corbels, pre-embedded steel plate 16 is embedded on the top surface of the corbel; the pre-embedded plate 16 is a steel plate made of steel with a standard rectangular cross-section, and the steel plate and the anchor bar are connected by perforated plug welding to form an integral mechanical anchor on the corbel. In the leg; the support seat 1 is composed of a steel plate with a pin hole in the middle part; the supp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap