Paper guiding unit, fixing device, and image formation device

A technology of guiding unit and paper, which is applied in the direction of electric recording process applying charge pattern, equipment of electric recording process applying charge pattern, electric recording technique, etc., can solve the problems of image scratching, poor conveying, inconvenient operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

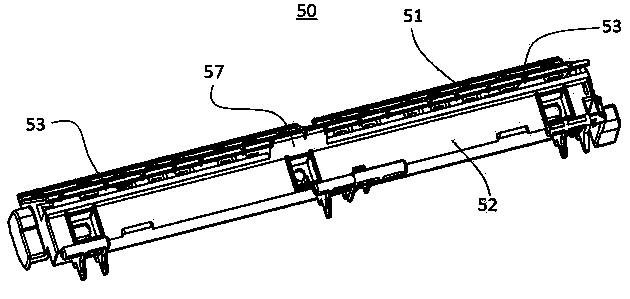

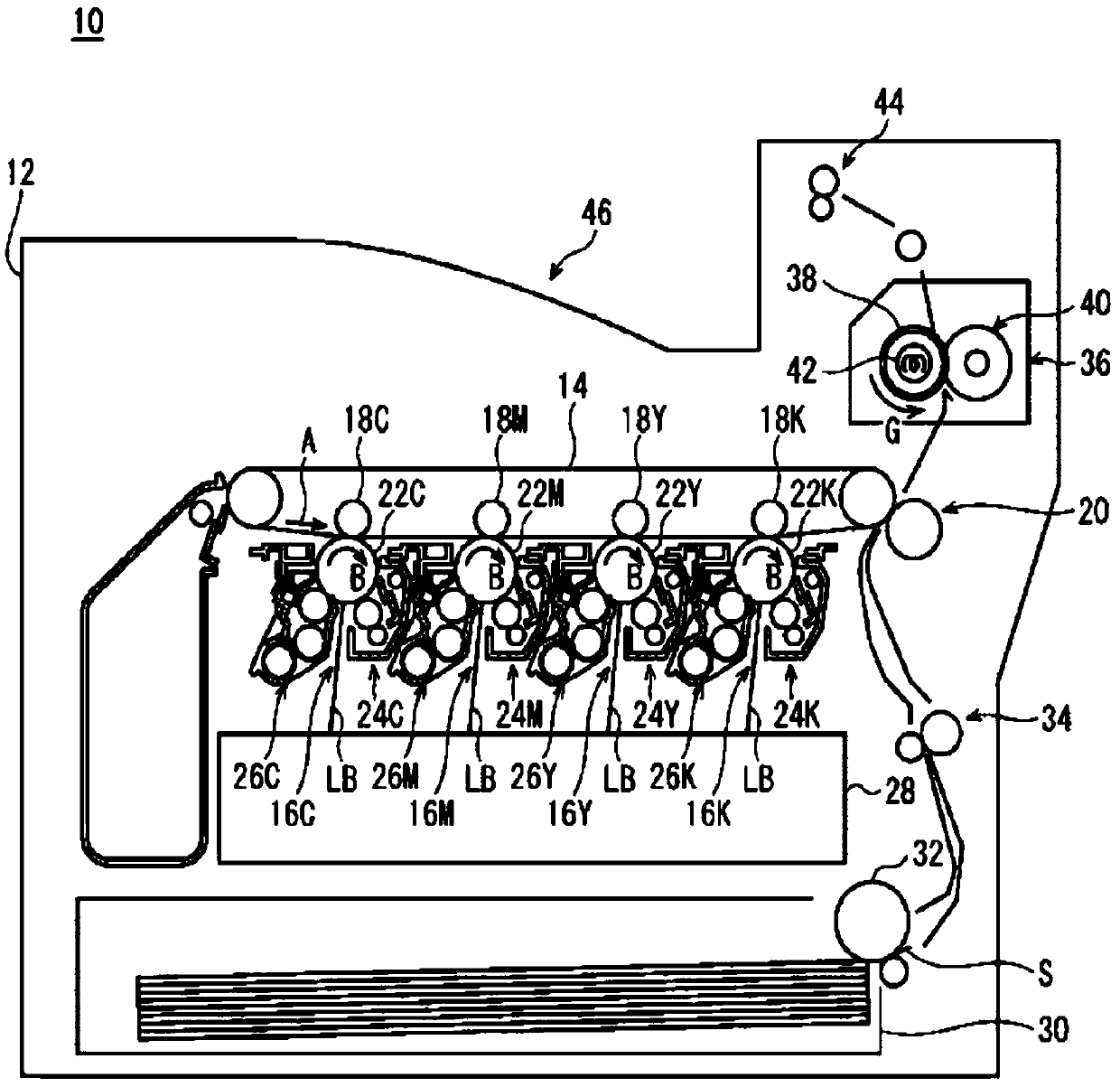

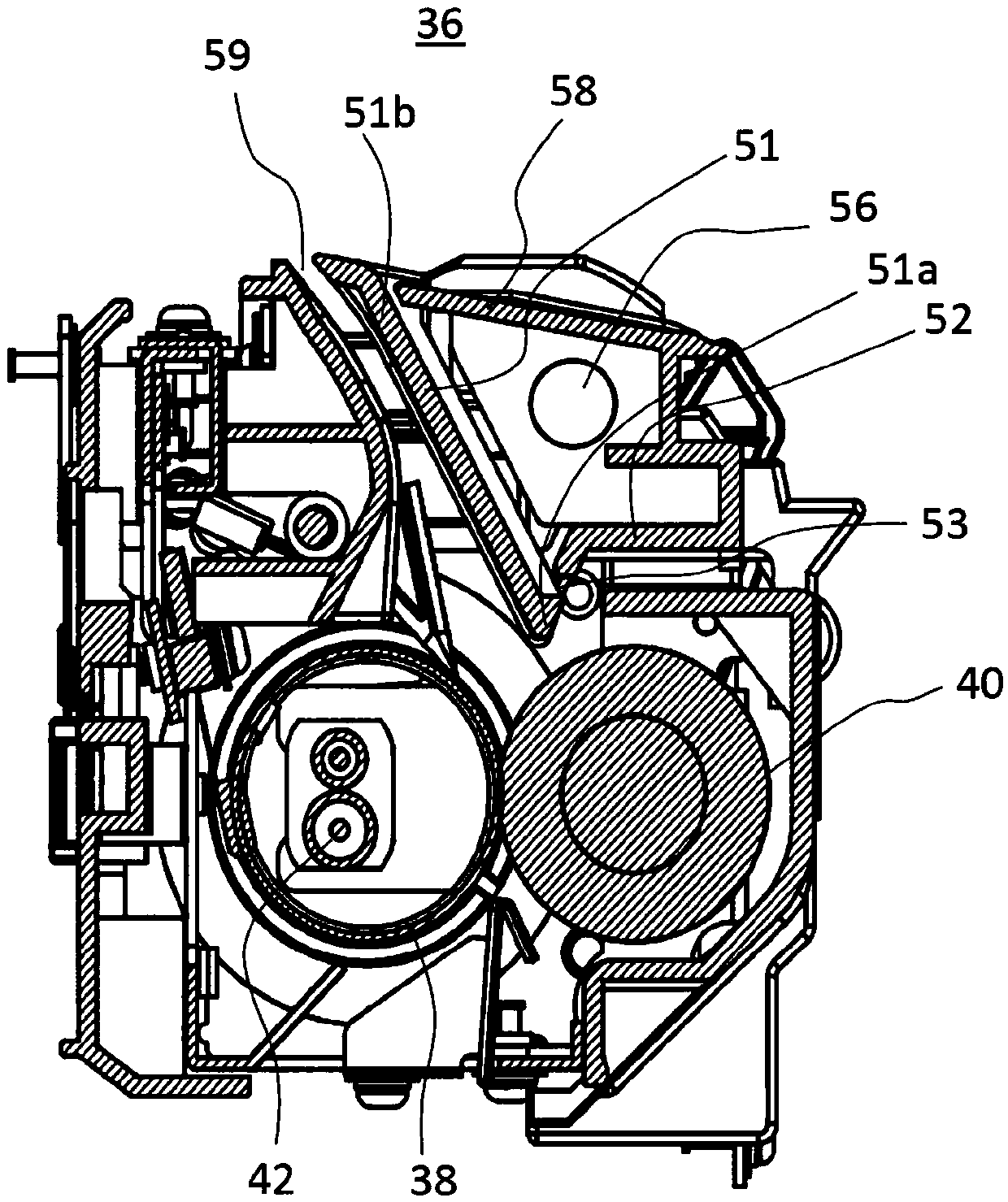

[0052] Below, refer to Figure 2 to Figure 5 A specific structure of the paper guide unit according to the first embodiment of the present invention will be described. image 3 It is a schematic diagram showing the paper guide unit according to the first embodiment of the present invention. Figure 4 It is a schematic perspective view showing the paper guide unit according to the first embodiment of the present invention. Figure 5 It is a schematic perspective view showing the paper guide unit according to the first embodiment of the present invention.

[0053] Such as Figure 2 to Figure 5 As shown, the fixing device 36 for fixing the transferred toner image on the paper includes: a fixing roller 38 arranged on the side of the fixing surface (the surface on which the toner image is formed) of the paper; The pressure roller 40 faces the fixing roller 38 on the (opposite surface to the fixing surface) side and sandwiches the paper conveyance path.

[0054] On the downstrea...

no. 2 approach >

[0063] The difference between the second embodiment and the first embodiment is that the connection portion 57 between the rail portion 51 and the extension portion 52 is divided into multiple sections, in other words, one or more openings are provided on the connection portion 57 . Image 6 is a schematic diagram showing a case where the connecting portion is provided with one opening, Figure 7 It is a schematic diagram which shows the case where two openings are provided in the connection part. By dividing the connection portion 57 between the rail portion 51 and the extension portion 52 into multiple stages, the area of the connection portion can be further reduced, and the end portion 51a of the extension portion 52 on the upstream side of the rail portion 51 in the sheet conveyance direction can be further reduced. The suppression of thermal expansion further suppresses the deformation of the rail portion 51 .

[0064] It should be noted that the shape and number of o...

no. 3 approach >

[0066] The guide rail part 51 and the extension part 52 can also be completely disconnected by the opening 53. In the case that the guide rail part 51 and the extension part 52 are completely disconnected by the opening 53, the guide rail part 51 and the extension part 52 can also be connected by a connecting part of other structures. Connected to be relatively movable.

[0067] E.g Figure 8 ~ Figure 12 As shown, the difference between the third embodiment and the first embodiment is that the guide rail part 51 and the extension part 52 are completely separated by the opening 53, and in addition, the extension part 52 and the guide rail for supporting the guide rail part 51 and the extension part 52 The portion support mechanism 58 is molded together by integral molding. Since integral molding is adopted, the cost can be reduced.

[0068] In addition, the guide rail portion 51 and the extension portion 52 are connected by a mounting mechanism as a connection portion, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com