Multi-target comprehensive optimization method for tool holder

A tool holder, multi-target technology, applied in the field of mechanical processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

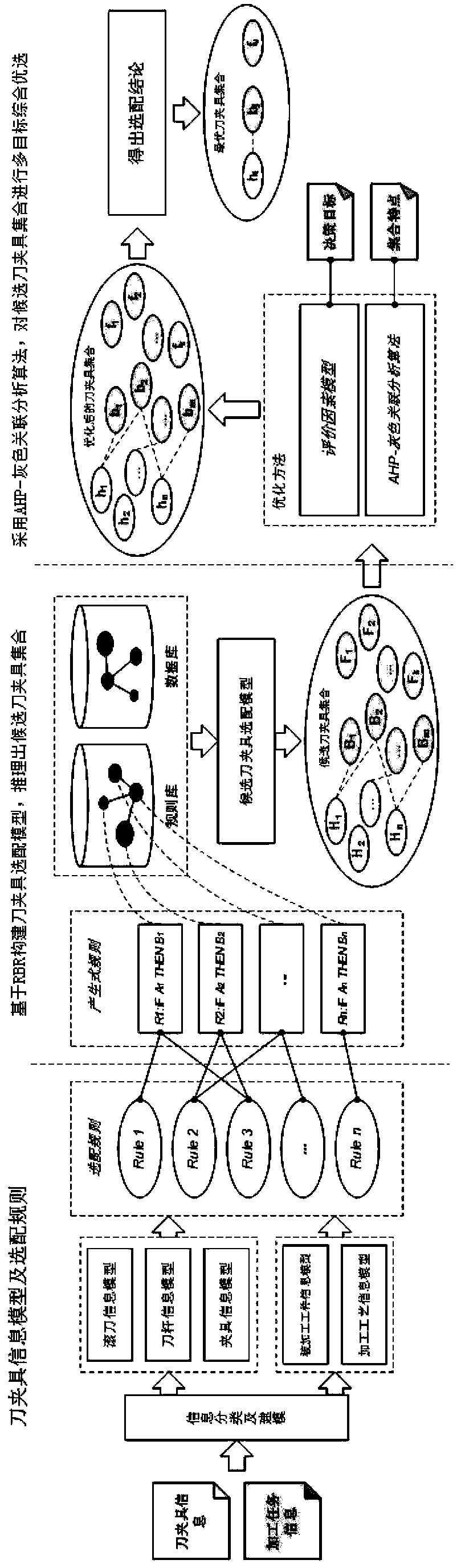

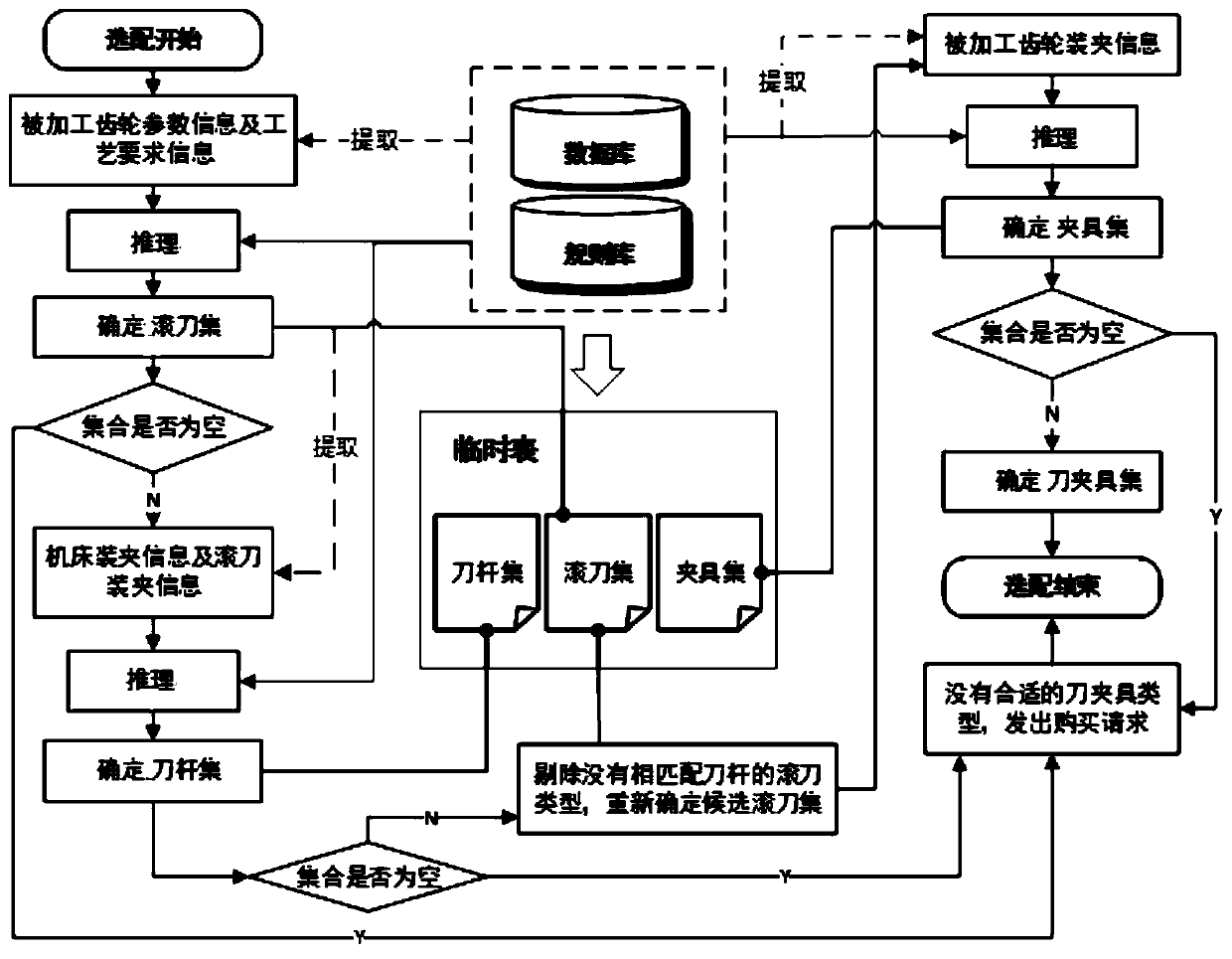

[0074] A multi-objective comprehensive optimization method for tool holders, refer to figure 1 shown, including the following steps:

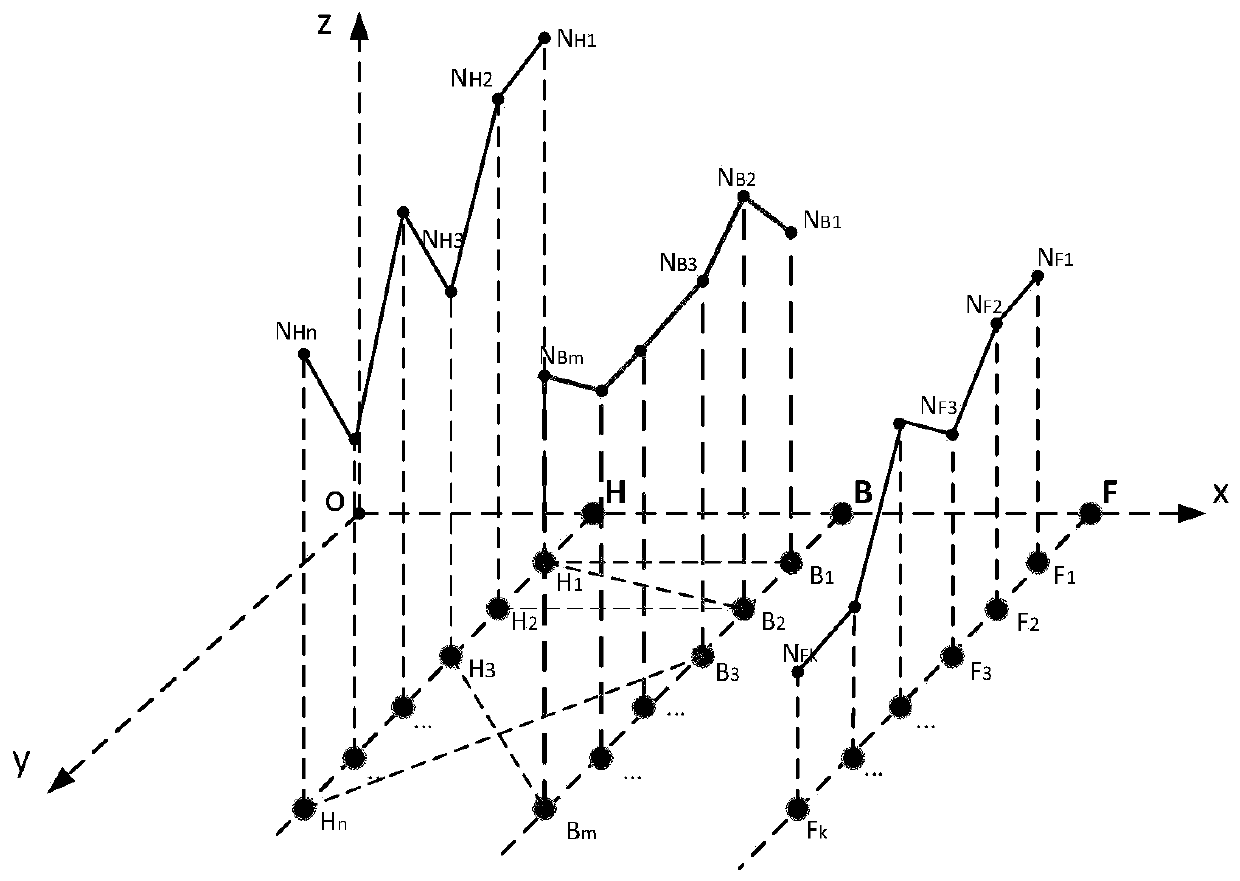

[0075] Step 1: Construct a tool holder selection model based on RBR, and infer a set of candidate tool holders T = {H B F} that meets the requirements of the processing task; where H is the set of candidate tools, B is the set of candidate toolholders, and F is the set of candidate fixtures. There is a mapping relationship between the candidate tool set H and the elements in the candidate tool holder set B;

[0076]Step 2: Use the AHP-gray relational analysis algorithm to perform multi-objective comprehensive optimization on the candidate tool holder set T={H B F}, so as to obtain the optimal tool holder combination that meets the multi-objective.

[0077] The preferred method of the present invention is applied to actual cases to prove the feasibility of the preferred method; case study is carried out with the gear processing workshop of a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com