Bile Arisaema forming machine and using method thereof

The technology of Dannanxing and forming machine is applied in the field of Dannanxing forming machine, which can solve the problems of low production efficiency of four-port extrusion structure, inability to ensure the roundness of extruded preparation strips, inconvenient measurement and control of medication accuracy, etc. Achieve effectiveness and uniformity, reduce manual workload, improve stability and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

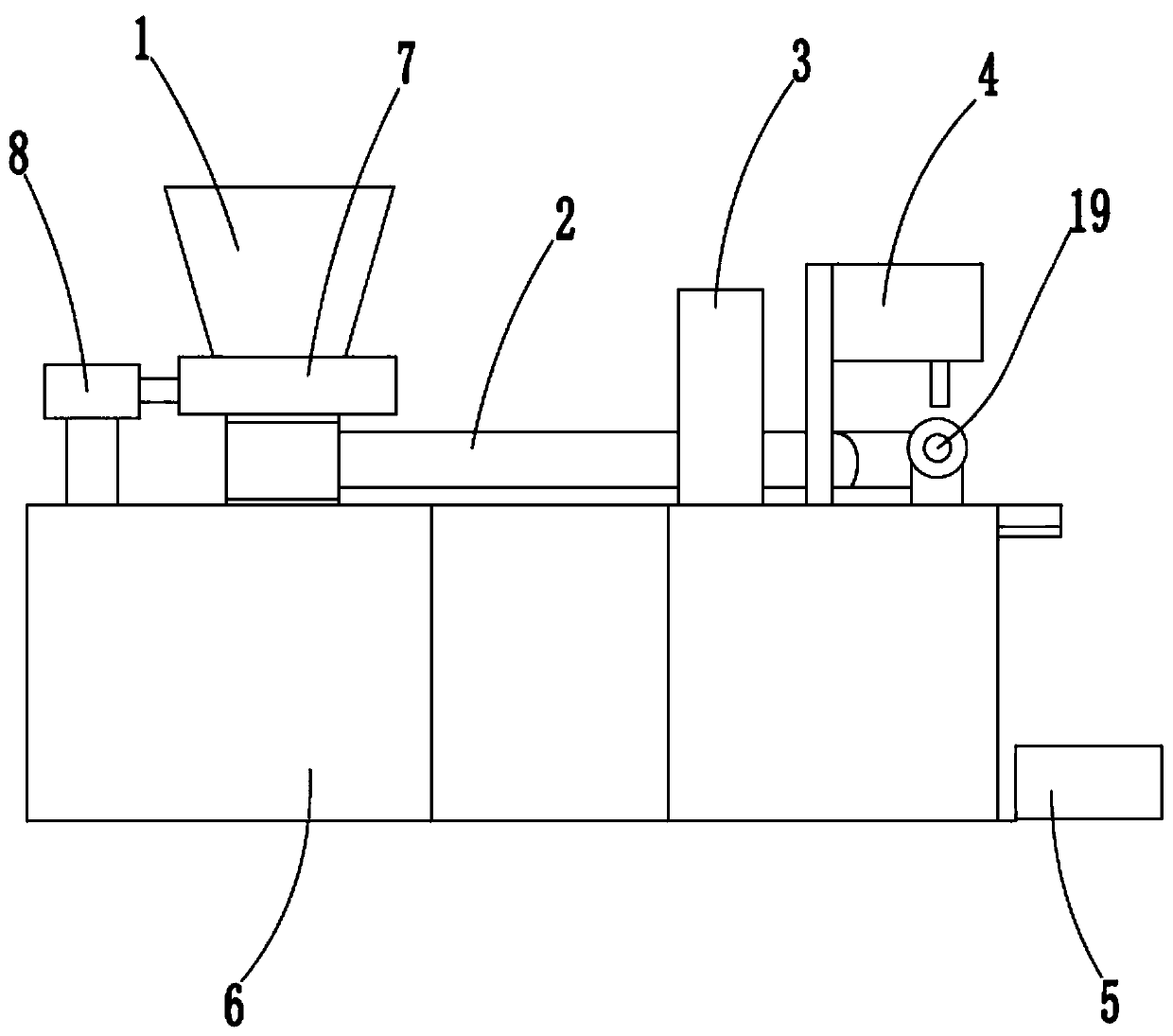

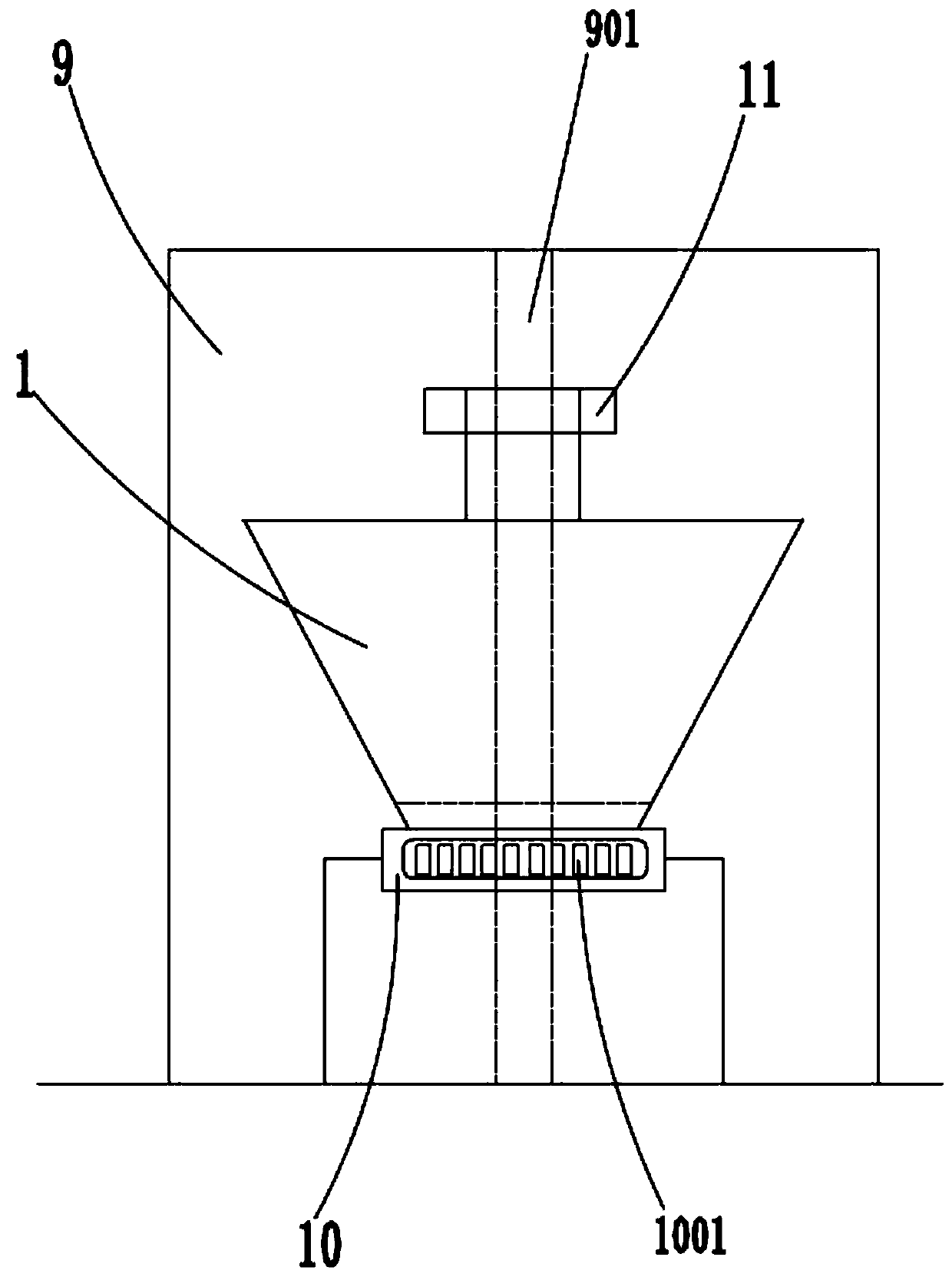

[0052] Such as Figure 1 to Figure 9 As shown, the Dannanxing molding machine of this embodiment includes a molding extrusion mechanism 7 communicated with the mixing funnel 1, and a stirring and pressing mechanism extending into the mixing funnel 1. The molding extrusion mechanism 7 includes a molding extrusion mechanism. The pressure chamber and the forming extrusion head 10 are provided with a plurality of discharge ports 1001 on the forming extrusion head 10, and a plurality of the discharge ports 1001 are arranged in rows, and the shape of the discharge ports 1001 is square. The number of outlets 1001 on the pressure head 10 is 10. The stirring and pressing mechanism includes a pressing head extending into the molding extrusion cavity. An extrusion block 1501 is provided with a driving device for driving the vertical reciprocating movement of the stirring and pressing mechanism. Vertical pressing control module for device operation.

[0053] In the Dannanxing forming ma...

Embodiment 2

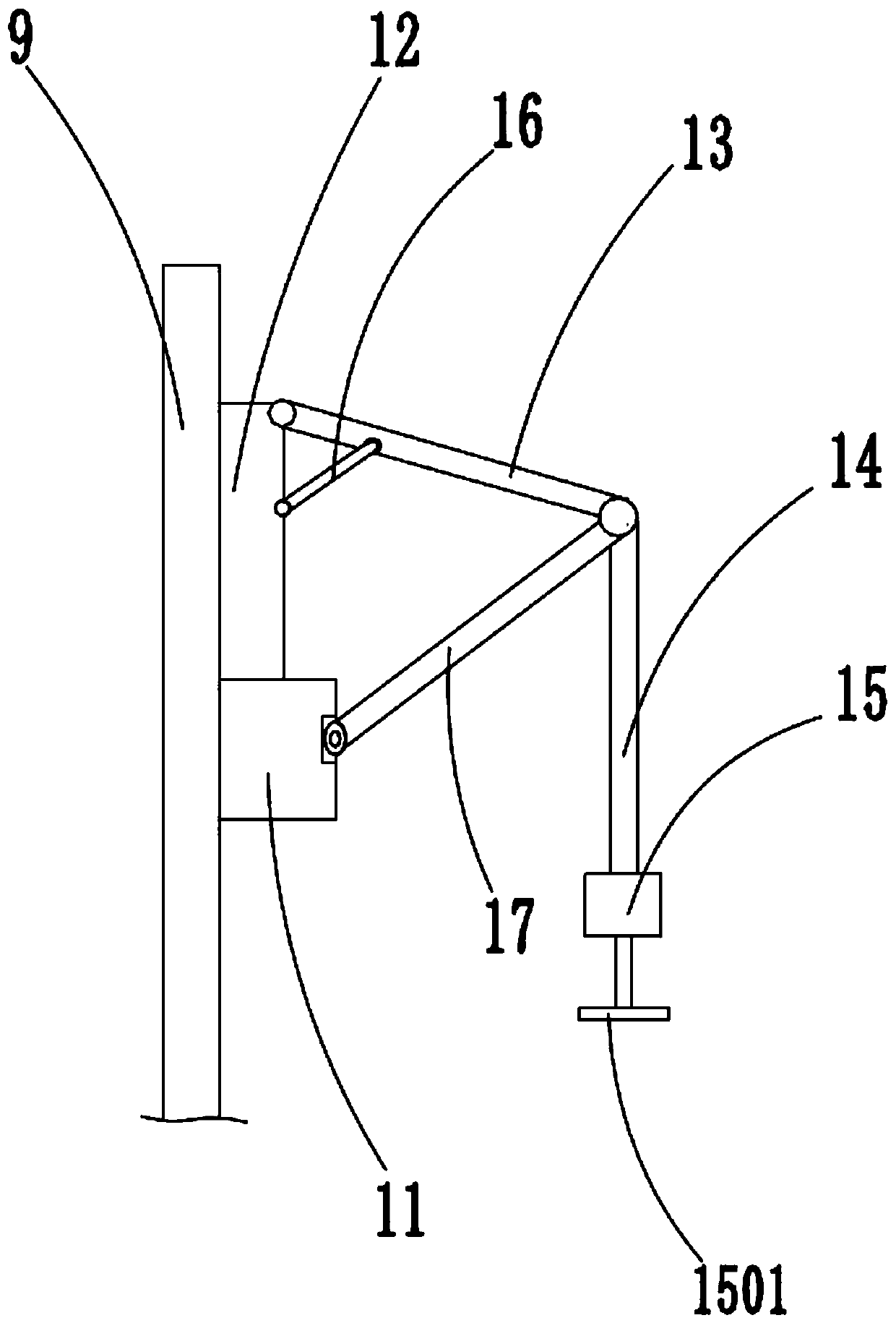

[0055] Such as Figure 1 to Figure 9 As shown, according to the Dannanxing molding machine described in Embodiment 1, the stirring and pressing mechanism of this embodiment also includes a pressing mechanism support plate 9 arranged beside the mixing funnel 1, and a pressing mechanism support plate 9 is provided on the pressing mechanism support plate 9. The vertical sliding groove 901 is provided with a material-pressing slider 11 inside the vertical sliding groove 901, and a connecting rod is connected between the material-pressing slider 11 and the material-pressing head.

[0056] Further, the connecting strut includes a pressing material displacement strut 17 hinged to the pressing slider 11, and an auxiliary stabilizing block 12 is arranged in the vertical sliding groove 901, and the auxiliary stabilizing block 12 is hinged with a pressing Material stabilizing strut 13, the ends of said pressing material displacement strut 17 and pressing material stabilizing strut 13 are...

Embodiment 3

[0060] Such as Figure 1 to Figure 9 As shown, according to the dannanxing molding machine described in embodiment 1 or embodiment 2, the dannanxing molding machine in this embodiment also includes a lateral pushing mechanism communicated with the molding extrusion cavity, and the lateral pushing mechanism includes Stepper motor 8, and the push block installation plate 18 that is connected with stepper motor 8, the motor shaft 801 of stepper motor 8 links to each other with lateral pushing block 1801, is provided with a plurality of sideways push blocks on push block installation plate 18. Briquetting block 1801. Set up a lateral pushing mechanism to carry out lateral and horizontal extrusion of the raw materials in the forming extrusion head, and cooperate with the vertical extrusion of the pressing head of the stirring and pressing mechanism to further ensure the uniformity of the extruded Dannanxing strip. The setting of two lateral push blocks is beneficial to correspond ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com