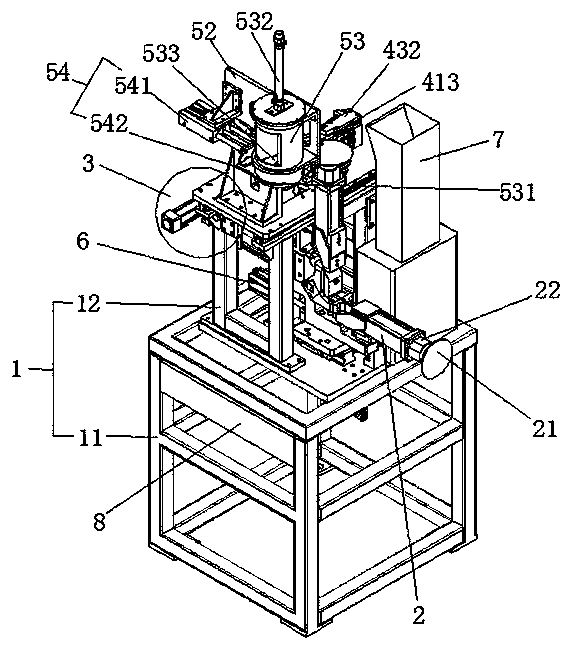

Automatic sheet replacing and polishing machine

A polishing machine and automatic technology, applied in the field of polishing machines, can solve the problems of increasing the production capital burden of enterprises and increasing labor costs, and achieve the effect of saving labor costs and speeding up the efficiency of replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

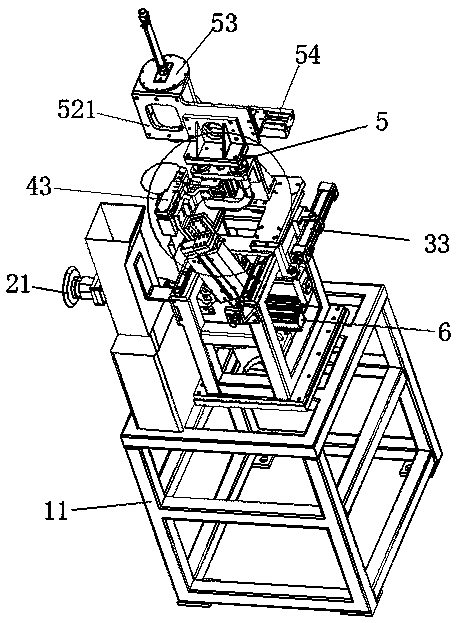

[0034] Automatic disc change polishing machine, the specific operation steps are:

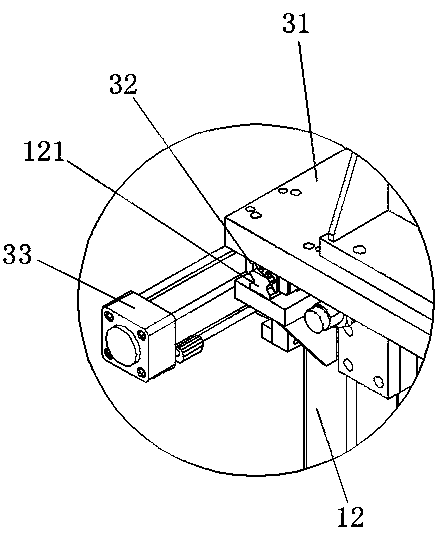

[0035] S1. The PLC controller 8 controls the movement of the first cylinder 33 to drive the movement of the first slide plate 31 so that the tearing mechanism 4 is located above the polishing wheel 21, and then moves correspondingly to the swing arm 2 of the pneumatic polishing head so that the lower port of the polishing wheel 21 is extruded connecting the first baffle plate 413, so that the polishing wheel 21 is positioned;

[0036] S2. The extension of the sixth cylinder 421 drives the first shovel plate 422 to slide and connect to the upper surface of the polishing wheel 21, and the first shovel plate 422 is located below the sand sheet, and then the seventh cylinder 431 moves downward to drive the first pressure plate 432 Move downward, so that the first pressing plate 432 is squeezed and connected to the first shoveling plate 422, and the second chute 434 below the first pressing plate 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com