Repairable mute tire

A tire and mute technology, applied in tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of reduced internal void ratio of materials, loss of noise reduction effect of tires, and reduced sound absorption capacity, and achieves reduction of natural frequency peaks and increases. Large market competition rate, the effect of reducing resonance noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

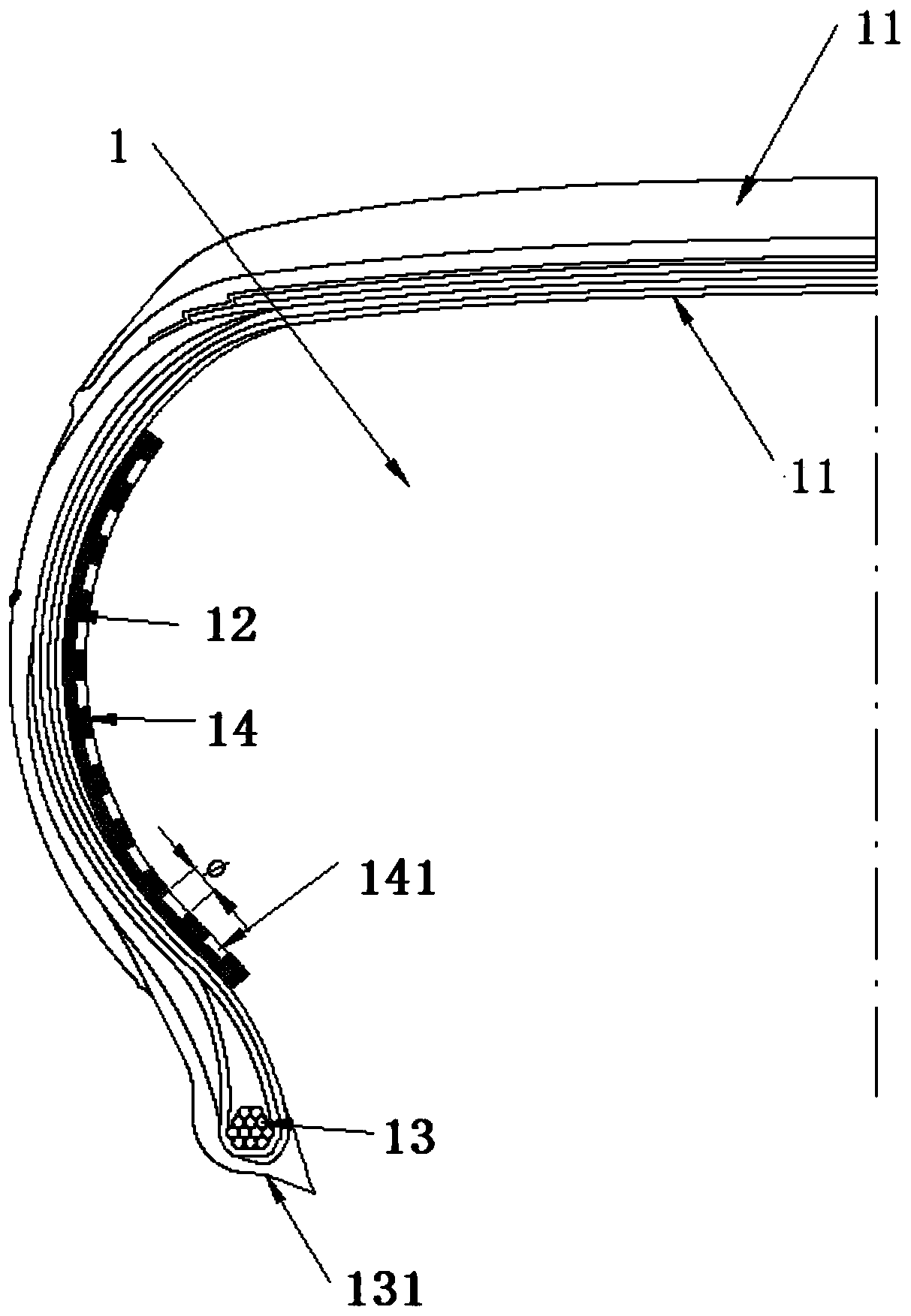

[0038] Experimental example 1: Tire B, the specification is 215 / 55R17: the width of the sound-absorbing cotton is 50% of the width of the inner wall of the sidewall, the lower side of the sound-absorbing cotton is 20mm from the edge of the tire toe, the thickness of the sound-absorbing cotton is 8mm, and there are no sound-absorbing holes on the sound-absorbing cotton.

experiment example 2

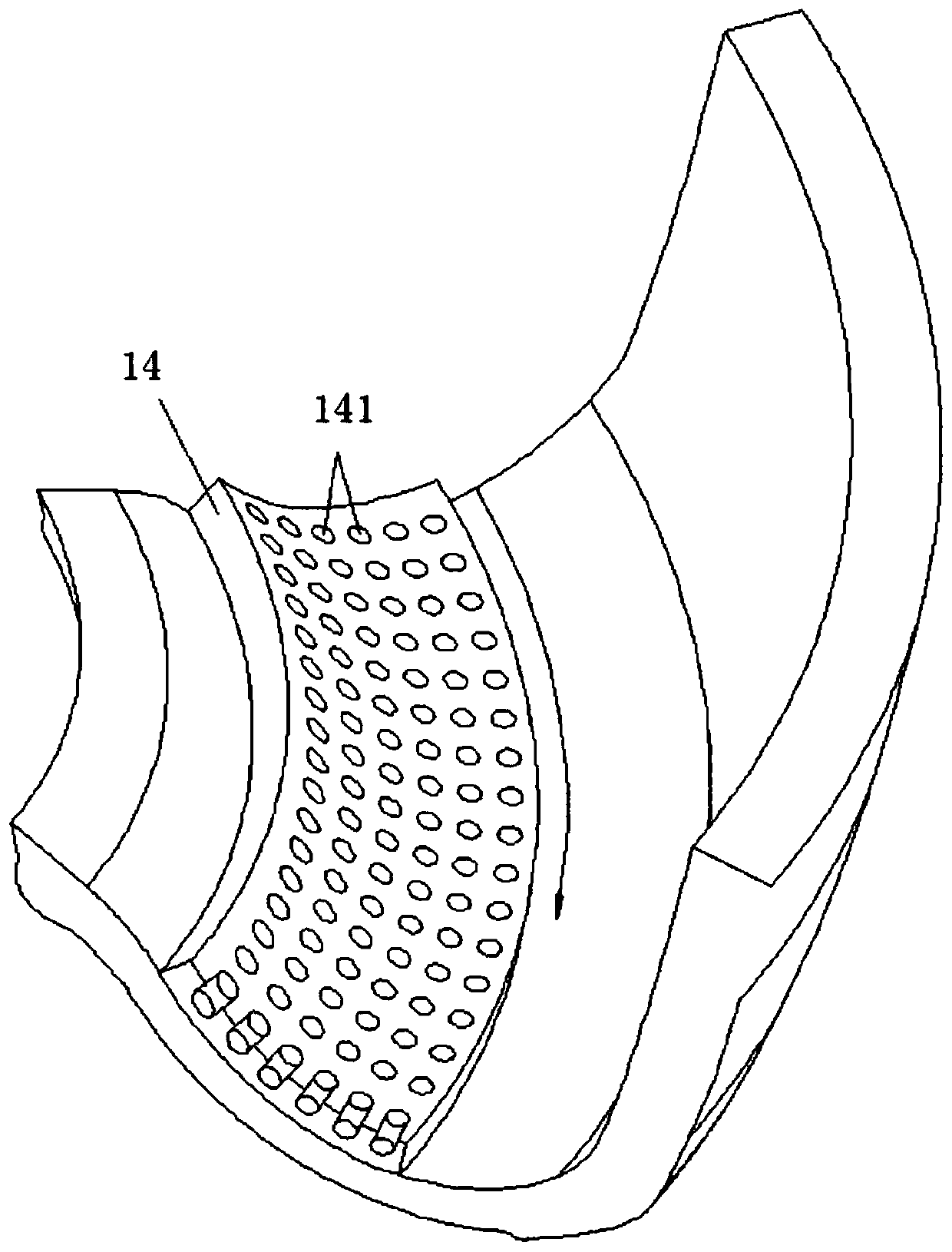

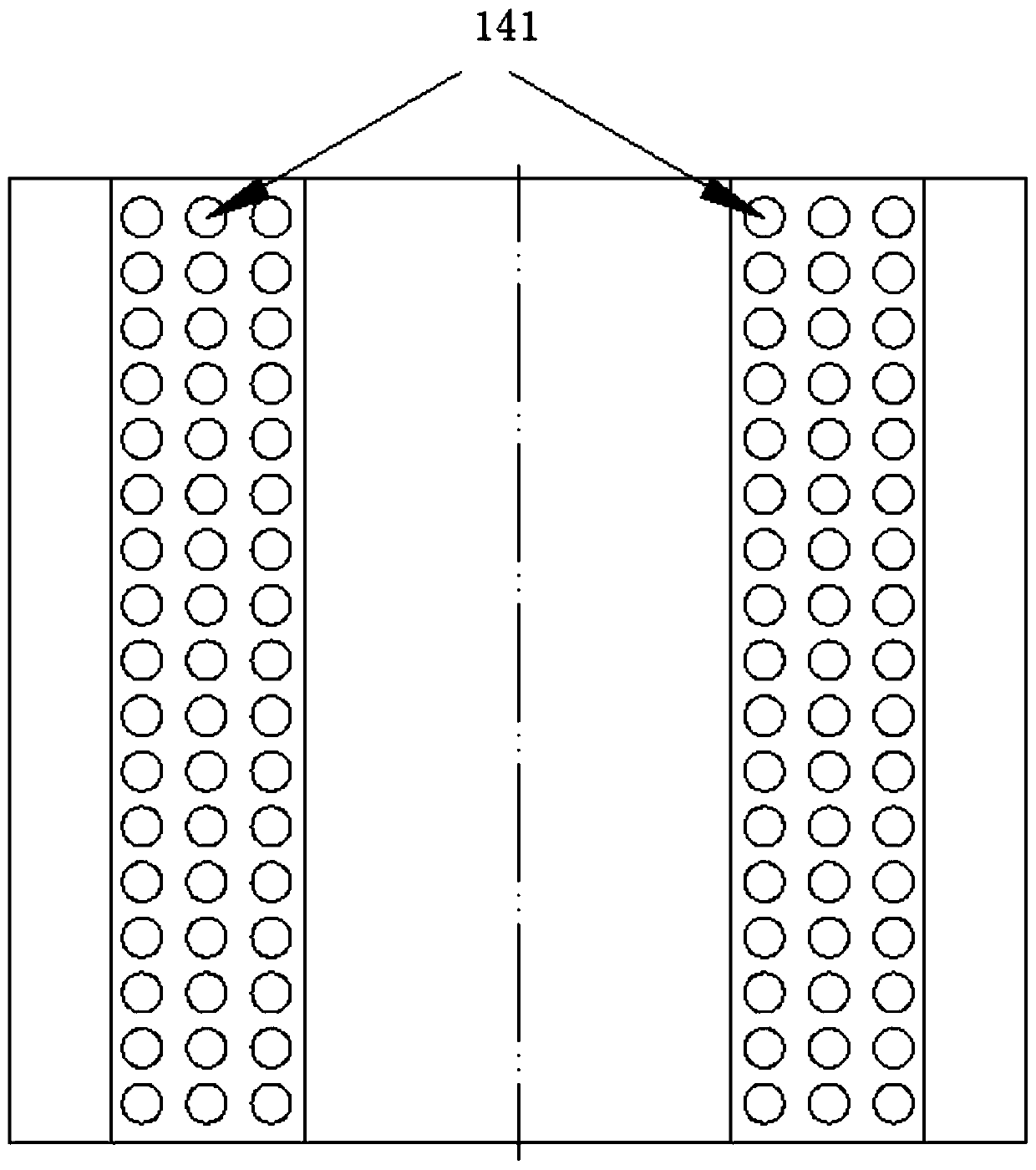

[0039]Experimental example 2: Tire C, the specification is 215 / 55R17: the width of sound-absorbing cotton 141 is 65% of the width of the inner wall of the sidewall, the lower side of the sound-absorbing cotton is 20mm from the edge of the tire toe, and the thickness of the sound-absorbing cotton is 8mm. No sound-absorbing holes are displayed on the sound-absorbing cotton.

experiment example 3

[0040] Experimental Example 3: Tire D, the specification is 215 / 55R17: the width of the sound-absorbing cotton is 85% of the width of the inner wall of the sidewall, the lower side of the sound-absorbing cotton is 20mm from the edge of the tire toe, the thickness of the sound-absorbing cotton is 8mm, and there are no sound-absorbing holes on the sound-absorbing cotton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com