Inclined shaft transport vehicle rail holding self-tightening device

A technology for transport vehicles and inclined shafts, applied in transportation and packaging, automatic starting devices, railway car body parts, etc., can solve the problems of high production cost, poor dust resistance, corrosion resistance, failure, failure or malfunction, etc. Achieve the effect of convenient installation and maintenance, safe and reliable performance, and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The mechanisms involved in the present invention or the technical terms used are further described below. In the following detailed description, reference texts accompanying the legends are a part hereof, and are presented by way of illustration of certain embodiments in which the invention may be practiced. We do not exclude that the present invention can implement other specific solutions and change the mechanism of the present invention without departing from the scope of use of the present invention.

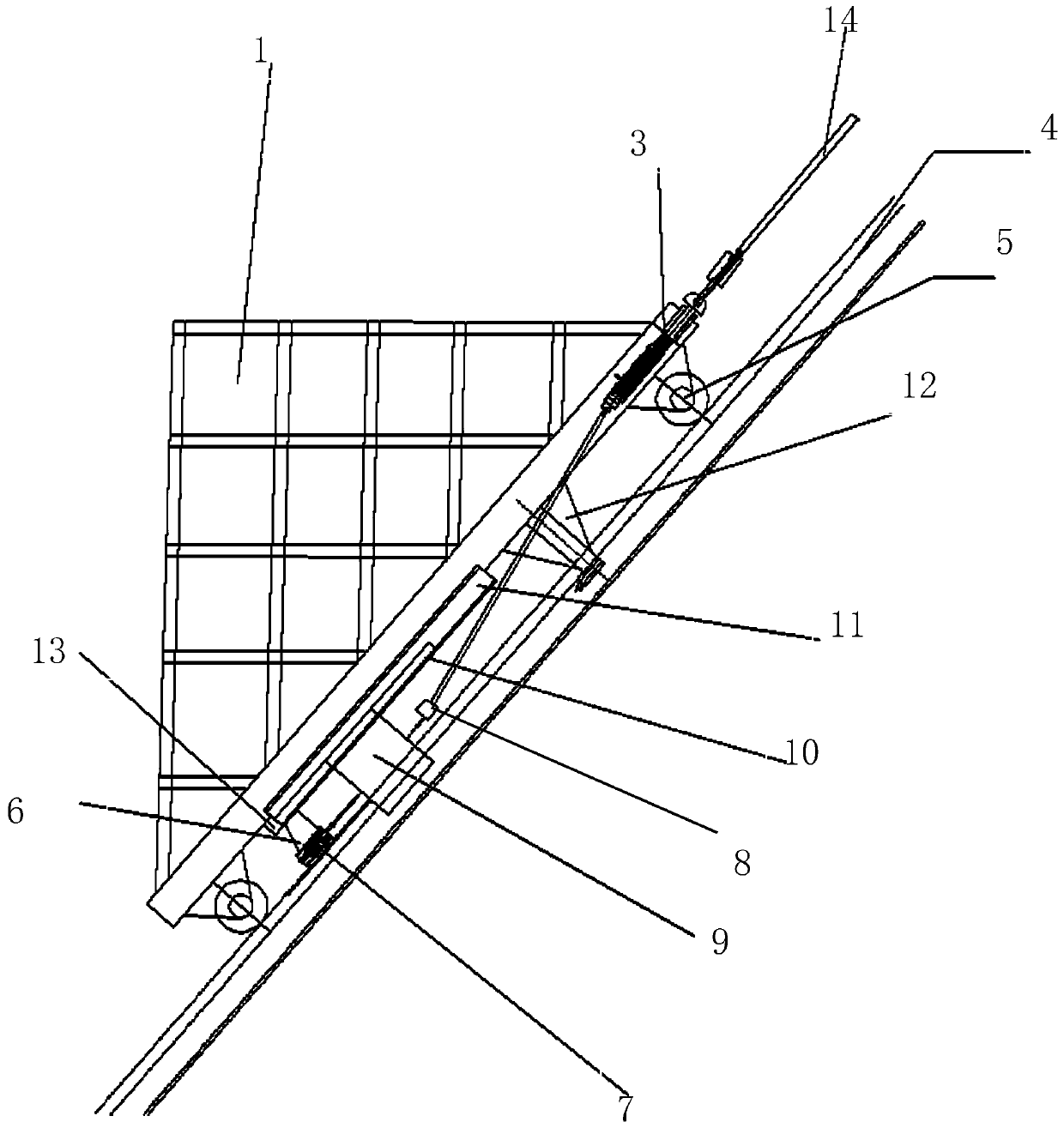

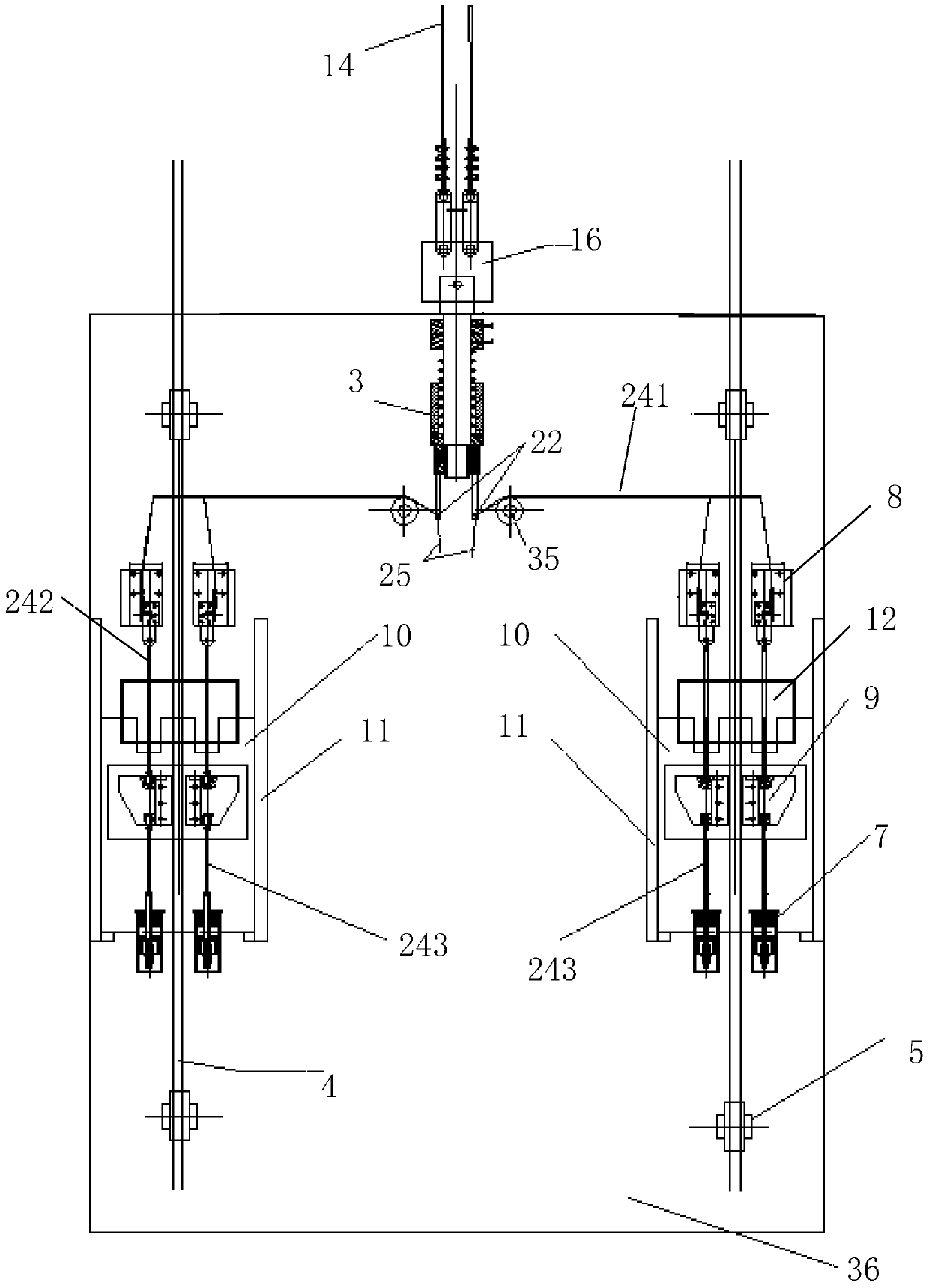

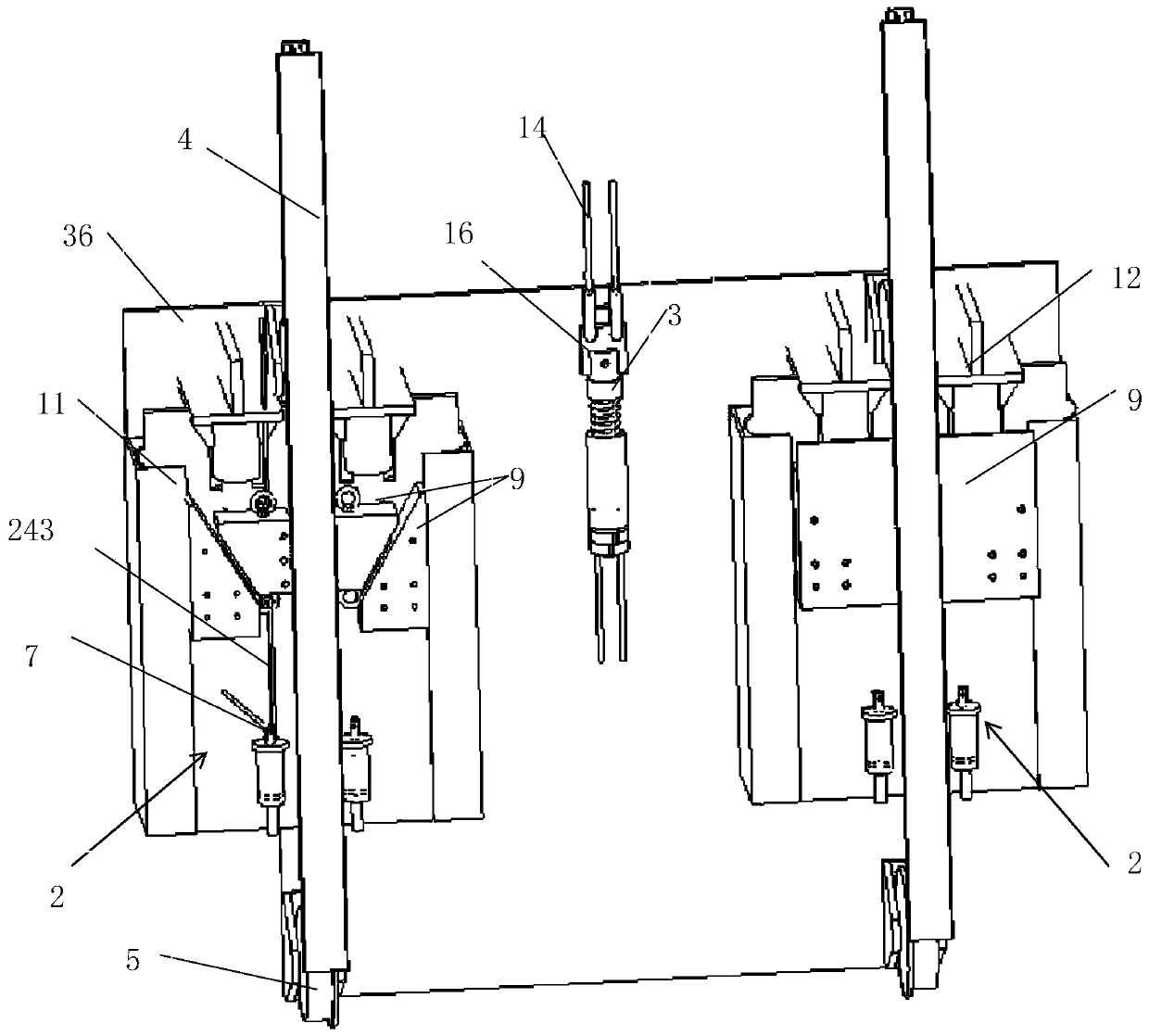

[0060] Such as Figure 1-15 As shown, the rail holding self-tightening device 2 of the inclined shaft transport vehicle of the present invention is installed at the bottom of the frame 36 of the inclined shaft transport vehicle 1, adjacent to the track 4. Specifically, the components of the rail-holding self-tightening device 2 include a decoupling mechanism, a brake locking mechanism 9, a locking spring mechanism 7 and a pressing mechanism 12, which are all located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com