Slewing bearing with sealing arrangement

A technology of slewing bearings and sealing devices, which is applied in the direction of rotating bearings, bearings, ball bearings, etc., and can solve problems such as long-term, frequent fixing of machines, and non-replaceable seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

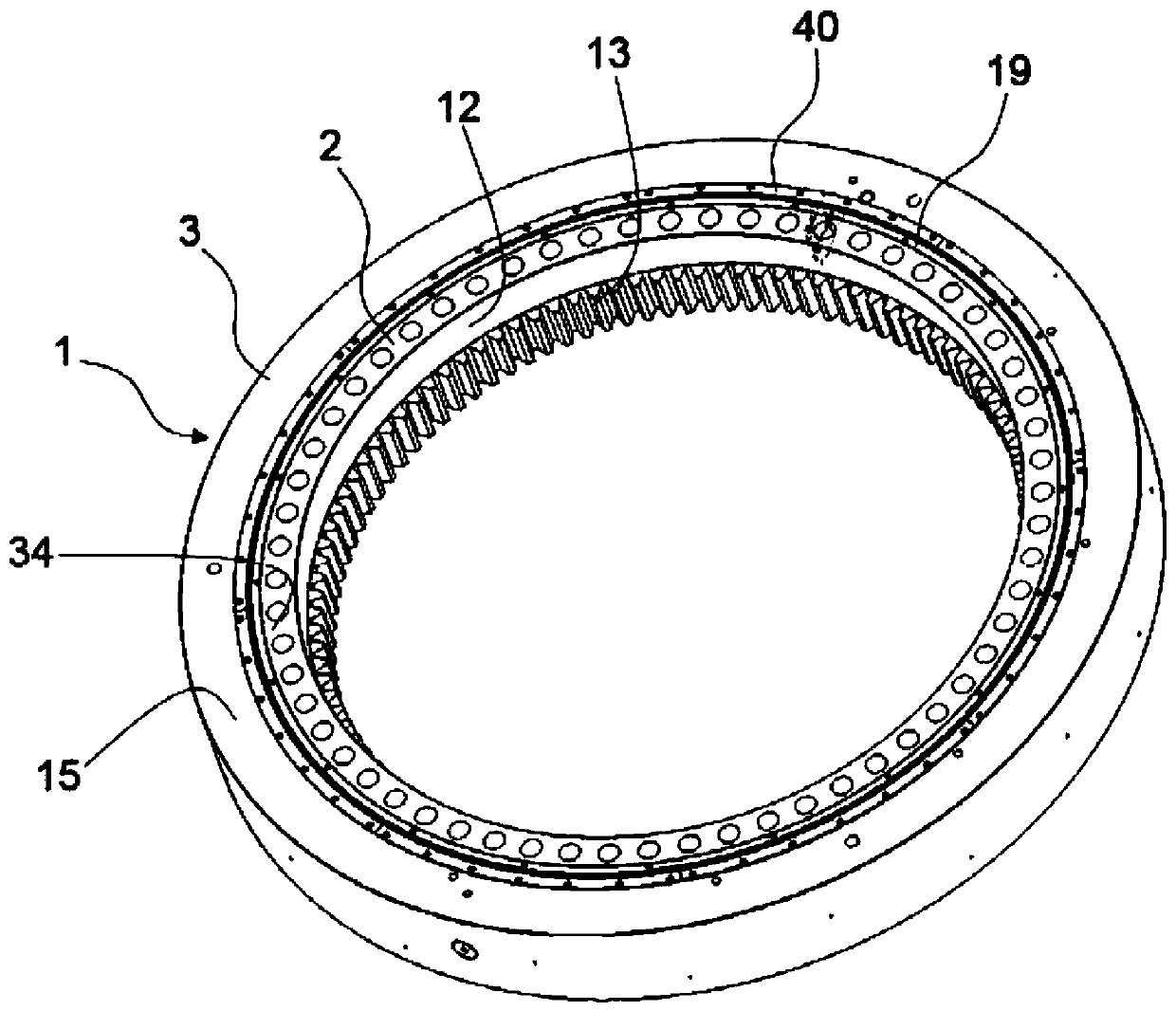

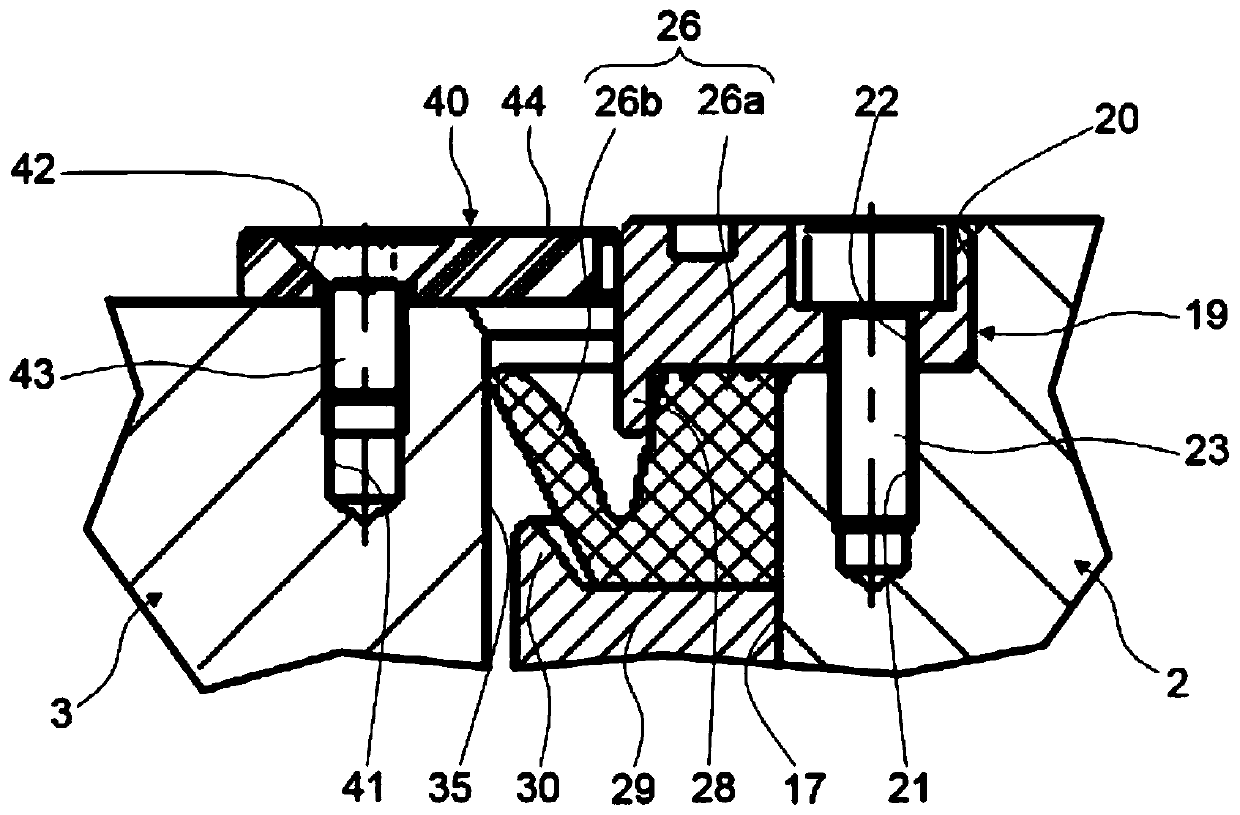

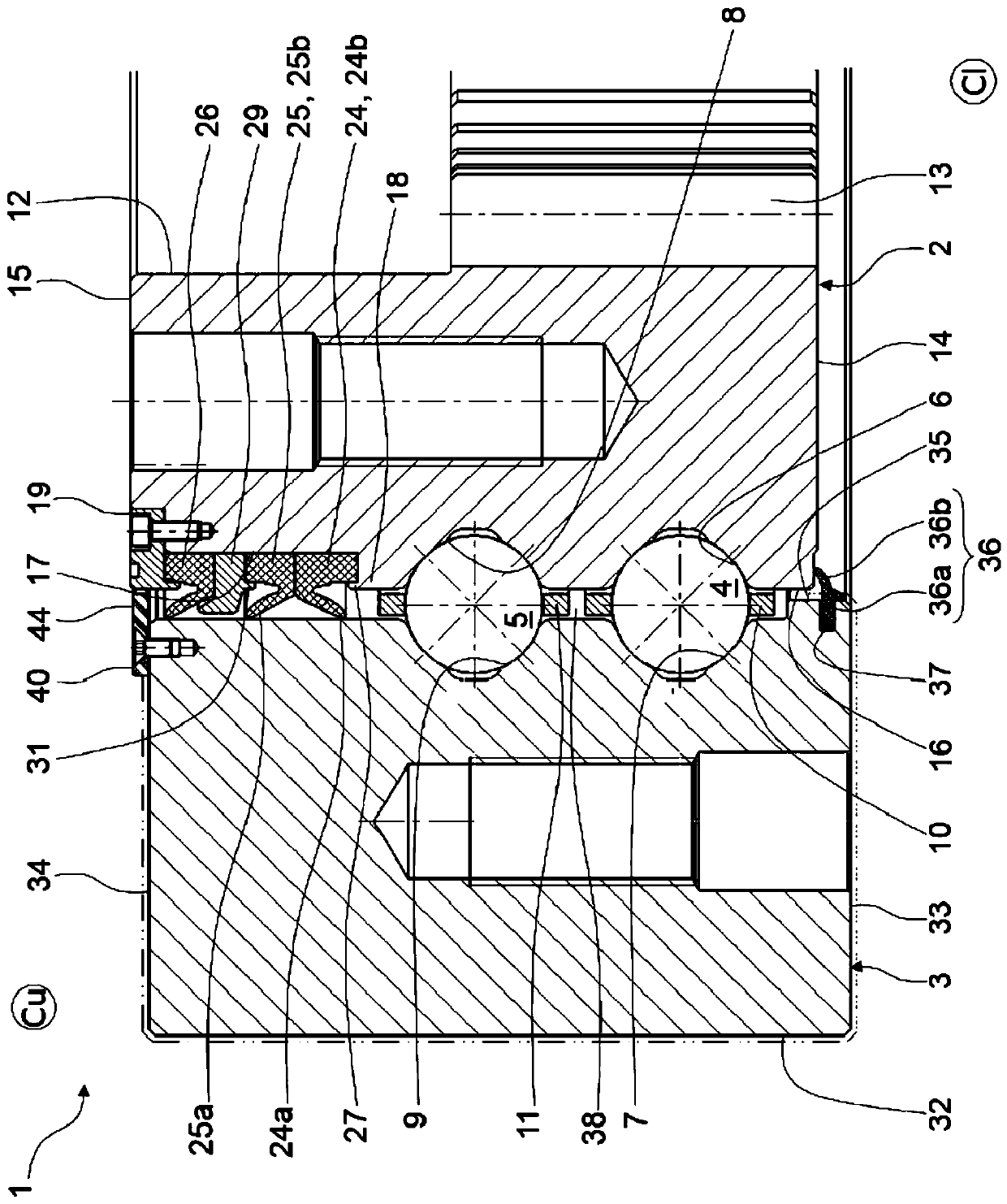

[0041] figure 1 and figure 2 A slewing roller bearing is shown which can be used in particular in marine applications such as tidal power stations, and which is generally designated with reference numeral 1 and has a large diameter. The slewing bearing defines: an upper side Cu, which is directly exposed to the marine environment; and a lower side Cl, which is arranged in a chassis (not shown).

[0042] The slewing roller bearing includes an inner ring 2, an outer ring 3 and two rows of rolling elements 4, 5. The rolling elements 4, 5 are arranged between these rings 2, 3 to form a radial thrust member capable of transmitting radial force ( radial thrust).

[0043] In the illustrated embodiment, the rolling elements 4, 5 are balls. The rolling elements can be of any other suitable type for the application, for example they can be rollers. The first row of balls 4 engages in raceways 6, 7 provided on the inner ring 2 and outer ring 3, respectively. The second row of balls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com