Electronic scale unbalanced loading visual tester

A technology of electronic scales and testing machines, applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of inability to manage the system, low detection efficiency, inaccurate detection, etc., to avoid data loss, high detection efficiency, and accurate detection results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

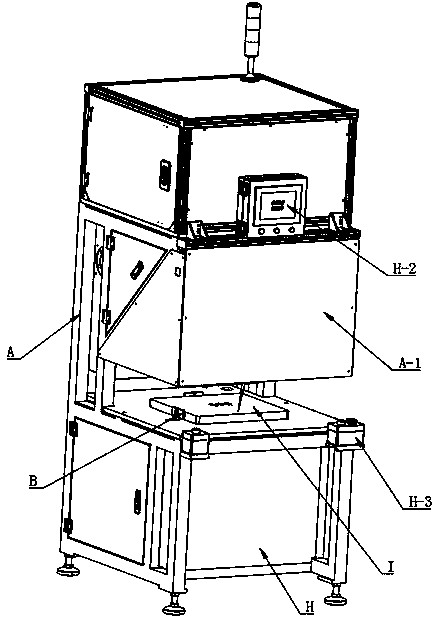

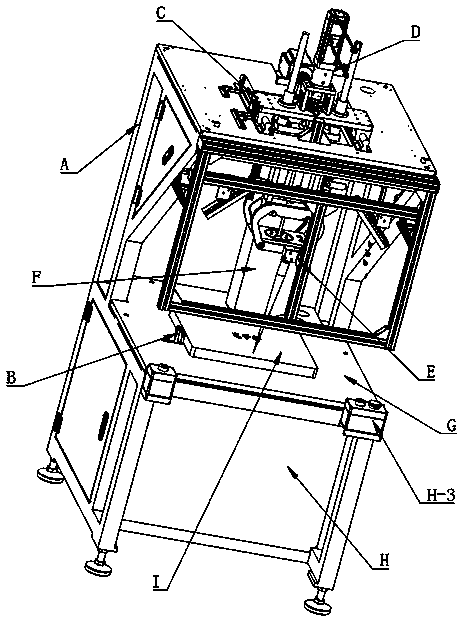

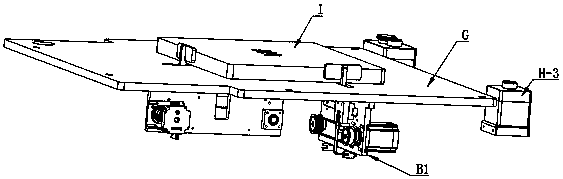

[0031] like Figure 1-10 Shown, a kind of electronic scale I eccentric load visual testing machine, comprises frame A, weight group F, conveying device, detection platform G, positioning device B, photographing module and control module H, the middle part of described frame A A detection platform G for carrying the electronic scale I to be detected is installed at the position, a positioning device B for positioning the electronic scale I is installed on the detection platform G, and a transfer device for transferring the weight group F is installed on the upper part of the frame A , located above the detection platform G, the weight group F is suspended on the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com