Intelligent construction site quality safety management system

A quality safety and management system technology, applied in the field of smart construction site quality and safety management system, can solve problems such as low work efficiency, difficulty in verifying the identity of workers and equipment, and poor communication in construction site quality and safety management, so as to improve the efficiency of rectification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

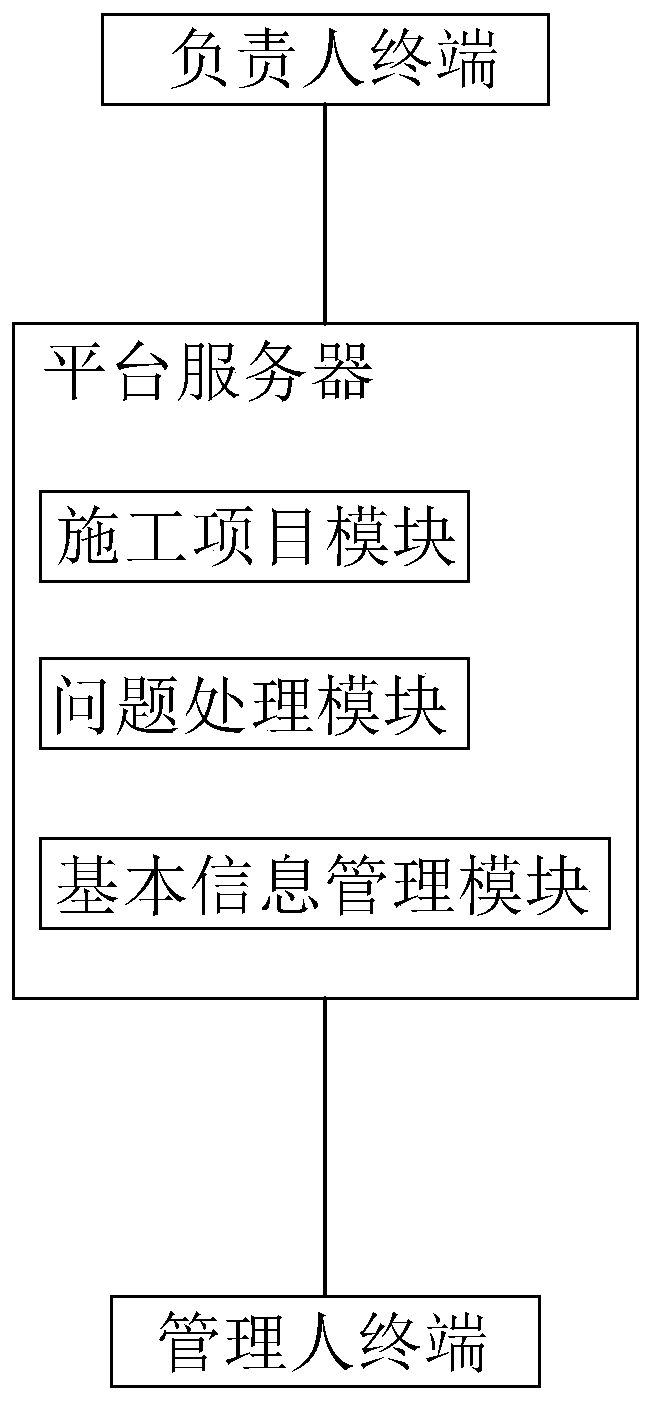

[0029] A smart construction site quality and safety management system, such as figure 1 As shown, it includes the platform server, the terminal of the manager and the terminal of the person in charge. The terminal of the manager and the terminal of the person in charge communicate with the platform server respectively; the platform server is used to store the 3D model of the project and the construction acceptance documents; When a quality and safety problem is found in the acceptance document, the manager terminal is used to obtain the first picture information where the quality and safety problem occurs, and mark the first picture information on the corresponding position of the 3D model of the project; the platform server receives the first picture information The rectification instruction is sent to the corresponding terminal of the person in charge; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com