High-efficiency rectification circuit

A rectifier circuit, high-efficiency technology, applied in the direction of circuit devices, AC power input conversion to DC power output, electrical components, etc., can solve the problems of low circuit efficiency, limited frequency bandwidth, etc., to reduce loss, improve matching performance, improve The effect of rectification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

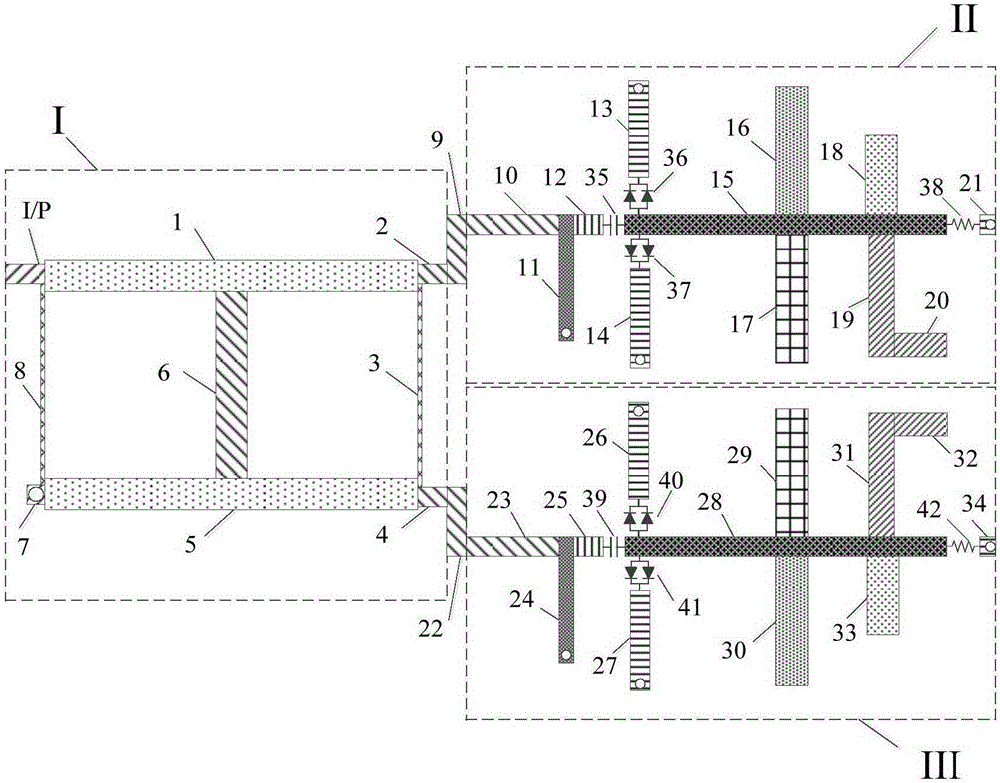

[0041] Such as figure 1 As shown, a high-efficiency rectifier circuit is characterized by comprising an upper microstrip structure, an intermediate dielectric substrate and a bottom metal floor, the upper microstrip structure is printed on the upper surface of the intermediate dielectric substrate, and the bottom metal floor is printed Manufactured on the lower surface of the intermediate dielectric substrate, the upper microstrip structure is composed of a two-section branch line coupler I, a first sub-rectifier circuit II, and a second sub-rectifier circuit III. The two-section branch line coupler passes through the The nine microstrip line 9 is connected to the first sub-rectifier circuit II, the two-section branch line coupler is connected to the second sub-rectifier circuit III through the twenty-second microstrip line 22, and the isolated ends of the two section line couplers pass Metalized vias are connected to the underlying metal floor. When the input power, frequency,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com