Green walnut huller

A peeling machine and walnut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of high breakage rate of green walnuts, reduce peeling efficiency, increase energy consumption, etc., to improve product appearance, improve peeling efficiency, Avoid the effect of walnut skin backlog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

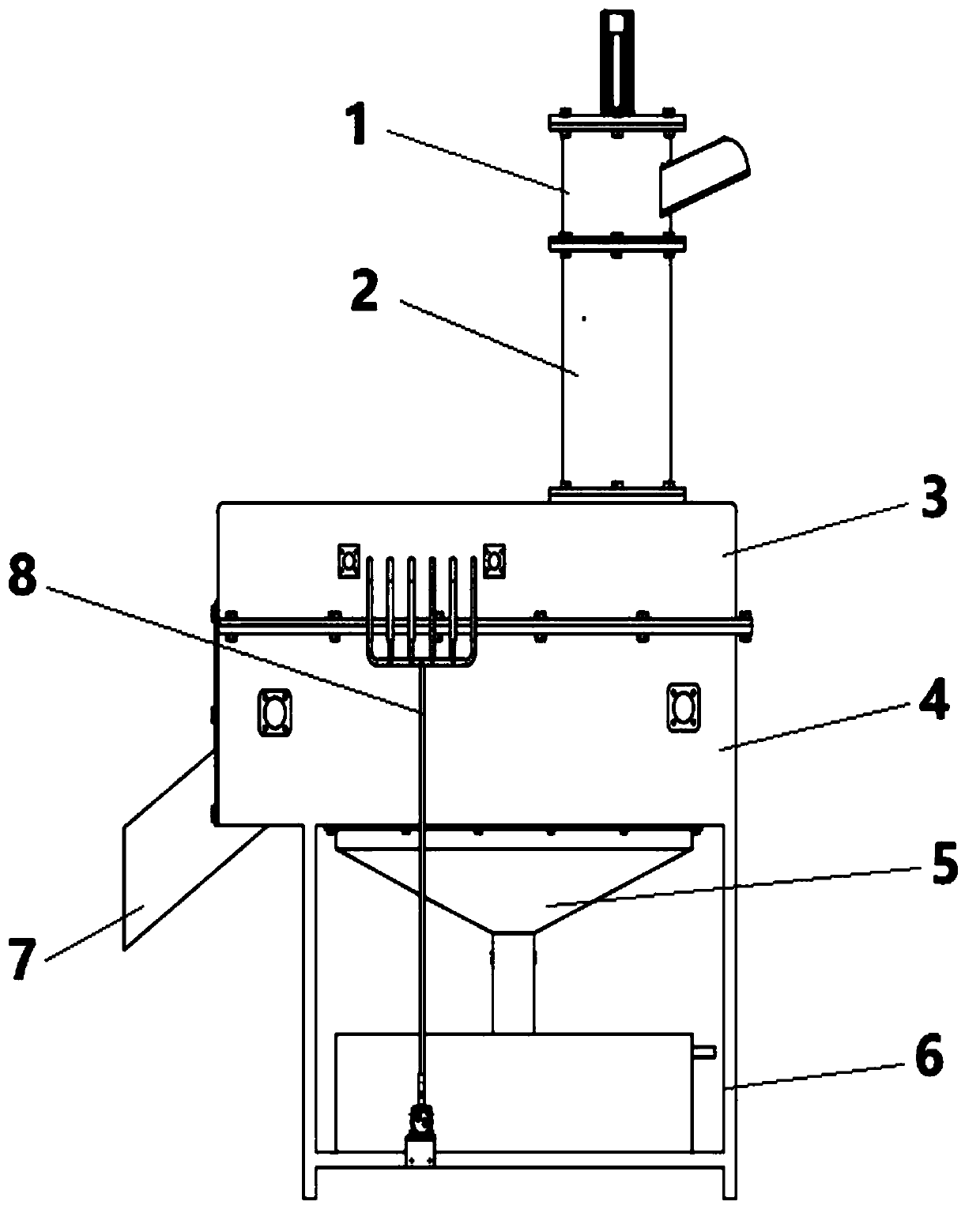

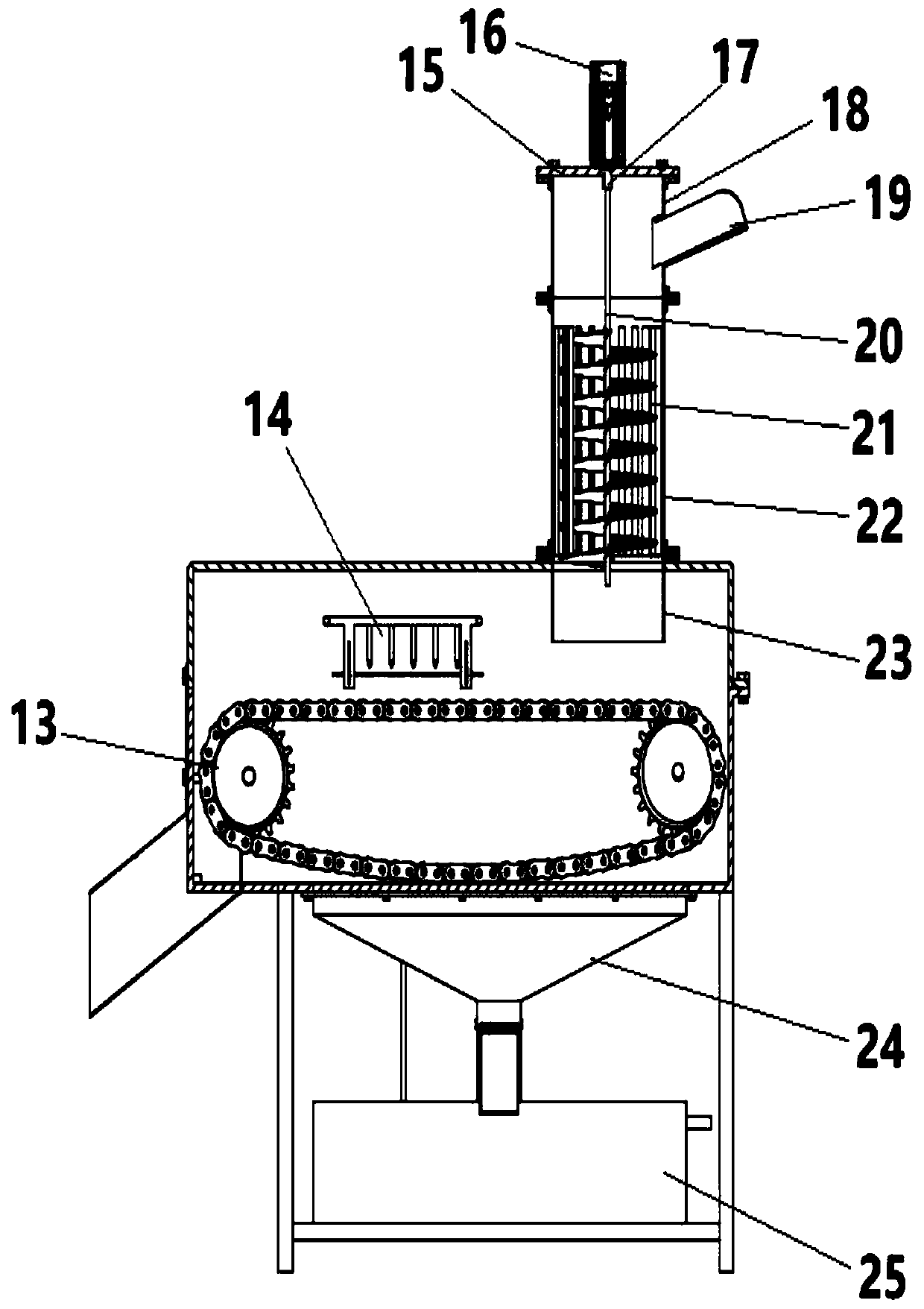

[0037] A green peeling walnut peeling machine, comprising a feeding device, a pre-peeling device, a high-pressure water gun peeling device, an upper casing 3, a lower casing 4, a frame 6 and a discharge port 7, and the pre-peeling device 2 includes a motor base 15, Motor 16, shaft coupling 17, screw feeder 20, cutter 21, pre-peeling device barrel 22 and lower base 23; Described motor 16 is fixed on the motor base 15 by screw, and motor base 15 is connected with feed by bolt The device 1 is connected, the feeding device 1 is connected with the barrel 22 of the pre-peeling device through bolts, the barrel 22 of the peeling device is connected with the lower base 23 through bolts, the lower base 23 is fixed on the upper casing 3 through screw connections, and the screw feeder The upper end of the 20 is connected to the motor through a coupling 17, and the lower end of the screw feeder 20 is fixed on the mounting hole 26 of the lower base 23 through a bearing; the high-pressure wat...

Embodiment 2

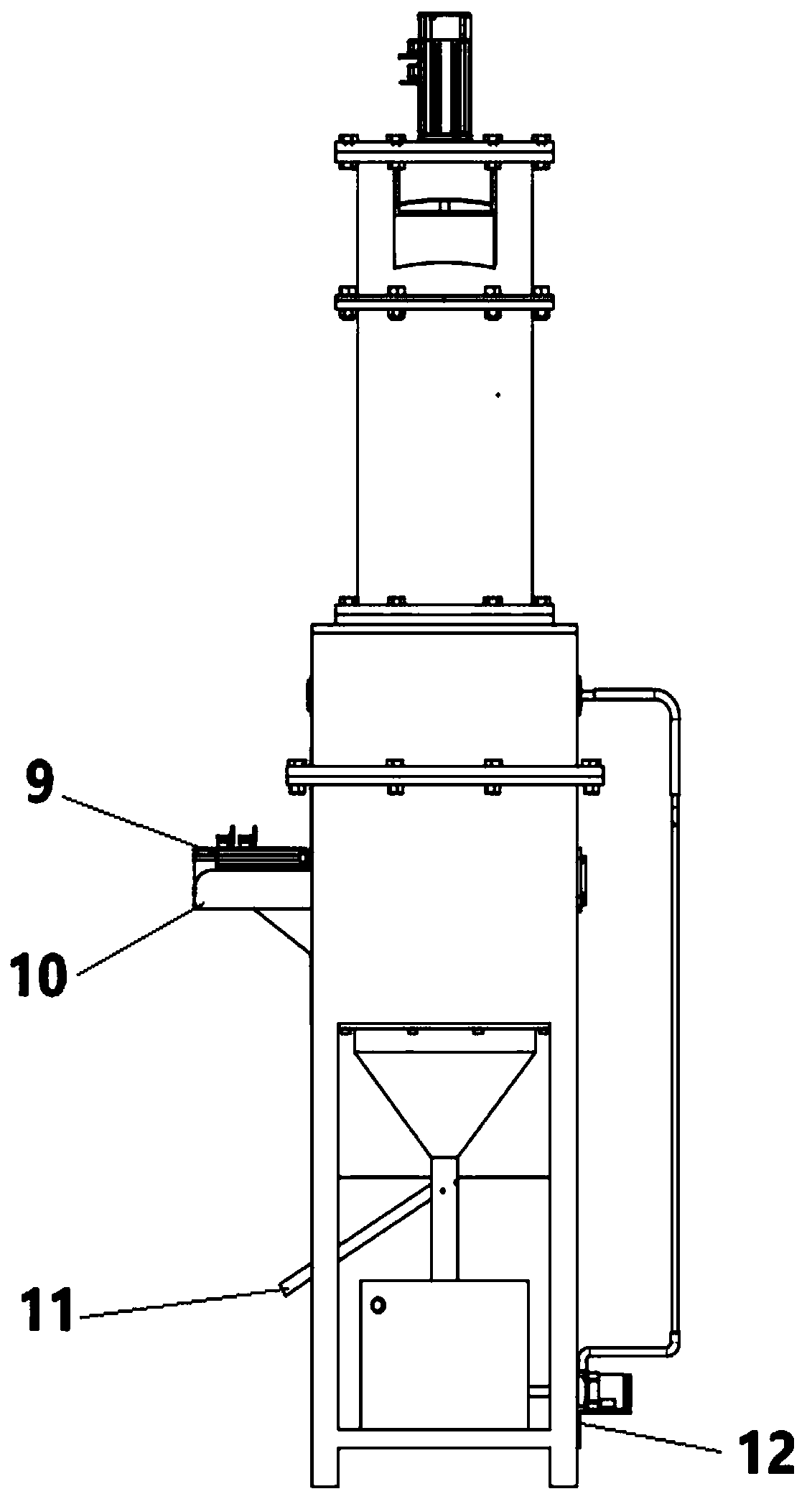

[0046] On the basis of Embodiment 1, it also includes a water collection device and a chain conveyor belt device; the water collection device 5 includes a slag water separator 11, a water collector 24 and a water tank 25; a separation screen is set on the slag water separator 11 38; the water collector 24 includes a water collector upper shell 35 and a water collector lower shell 36, and the water collector lower shell 36 is provided with a slag-water separator installation hole 37; the water tank 25 is provided with A water collector installation hole 40 , a water injection port 42 and a water outlet 41 .

[0047] The water collector 24 is fixed on the lower casing 4 by screws, and the slag-water separator 11 is connected and fixed on the lower housing 36 of the water collector through the mounting holes 39 with screws, and the slag-water separator 11 and the water collector The lower housing 36 is at an angle of 60°; the upper housing 35 of the water collector is funnel-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com