Separate plate type suction system

A suction system and sliced technology, applied in the direction of smoker's products, applications, tobacco, etc., can solve the problems of central carbonization, unevenness and incompleteness of tobacco materials, achieve stable carbonization process, improve heating efficiency, increase The effect of suction concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

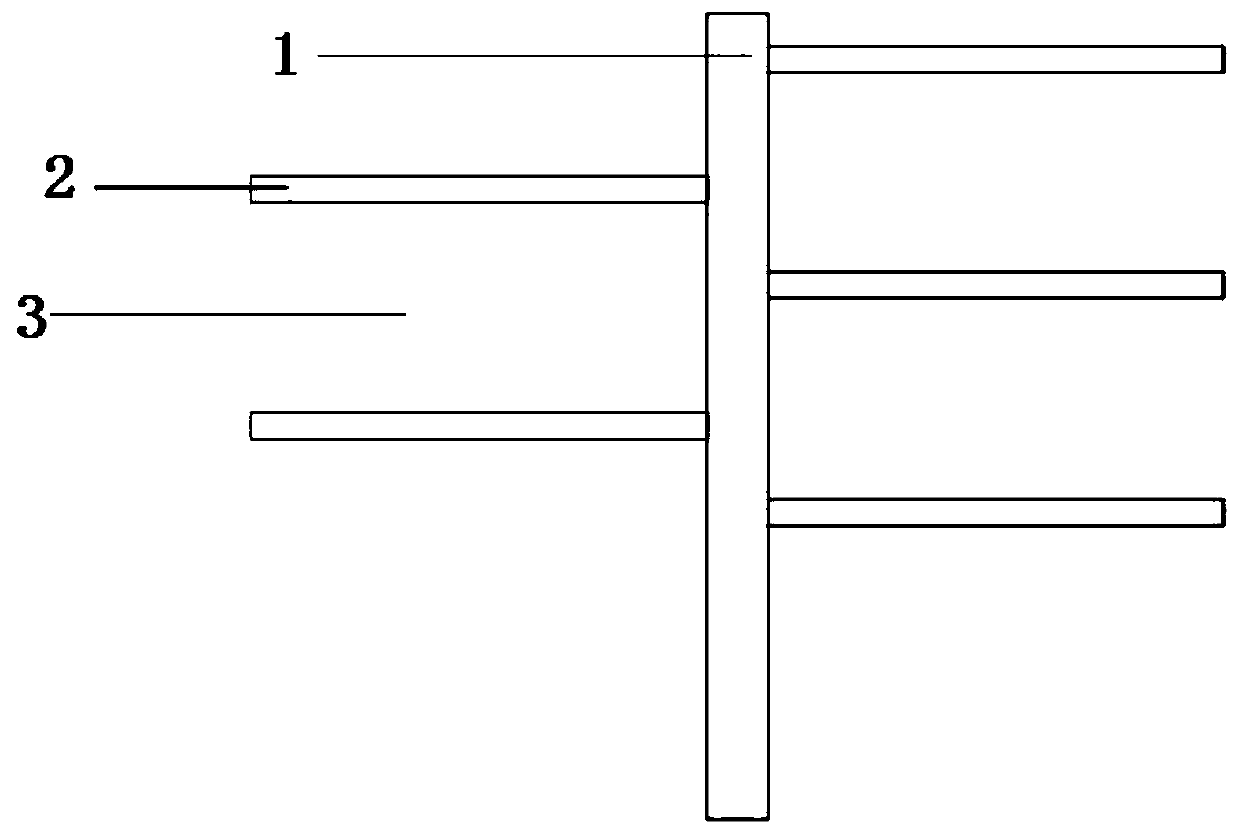

[0027] A sliced suction system, the sliced suction system includes a central heating component, one side of the central heating component 1 is snap-connected with two heating sheets 2, and the other side is detachably connected with three A heating sheet 2, the central heating component 1 is electrically connected to the heating sheet 2 .

[0028] The heating chips 2 are arranged parallel to each other.

[0029] The heating sheet 2 has an upper surface and a lower surface with the largest area, and the upper surface or the lower surface is arranged vertically to the central heating component 1 .

[0030] A material cavity 3 is formed between two adjacent heating sheets 2 for placing tobacco material sheets or tobacco material blocks to be heated.

[0031] The sliced suction system also includes a control system, which is electrically connected to the heating sheet 2 and controls the heating sheet 2 to heat or stop heating.

[0032] The distance between two adjacent hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com