Waterproof and breathable vamp and production process thereof

A production process and breathable technology, applied in the direction of footwear, shoe uppers, footwear, etc., can solve the problems of poor waterproof effect, poor air permeability, slow production speed of shoe uppers, etc., achieve good waterproof effect, increase production speed, increase The effect of the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

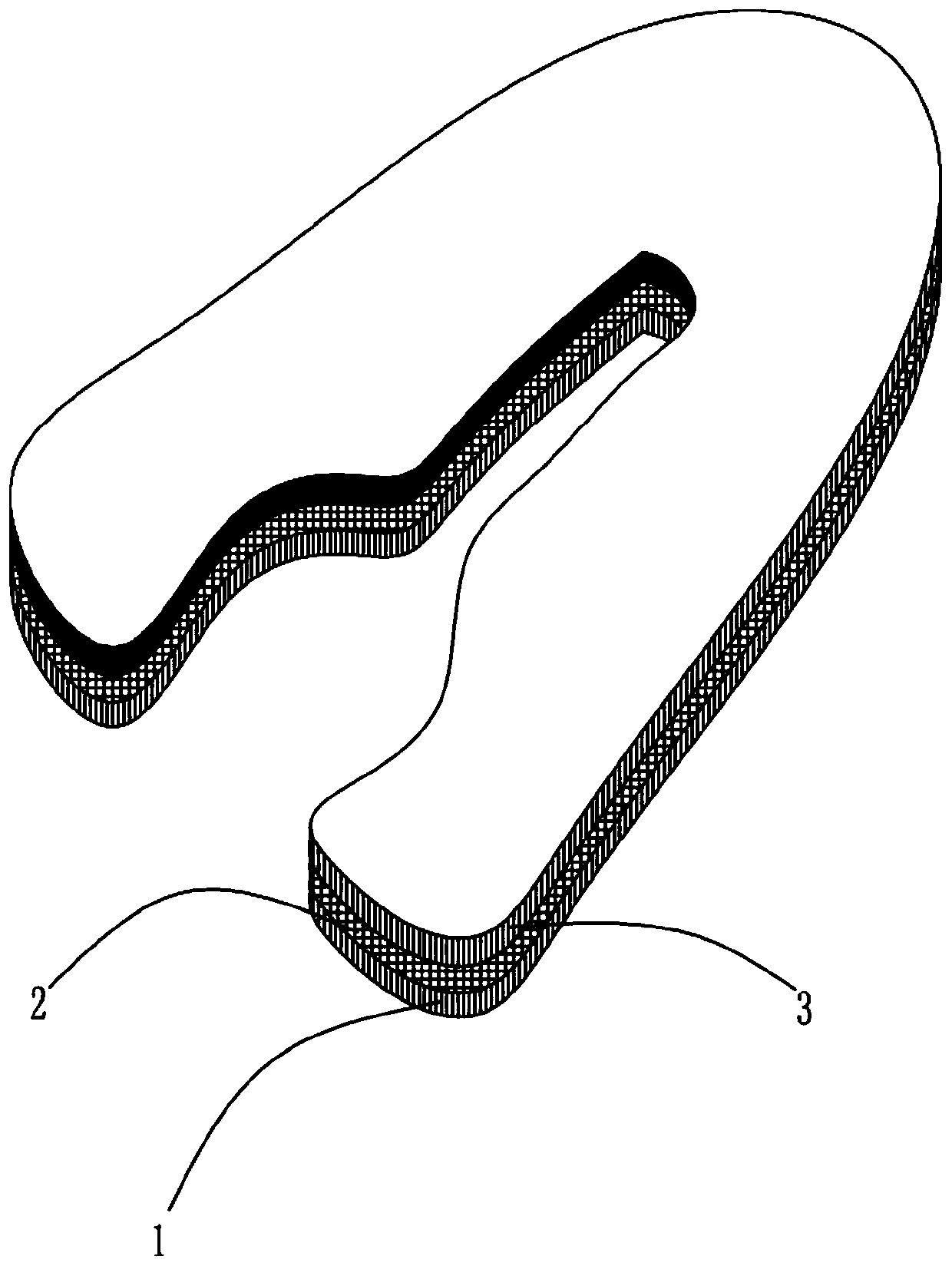

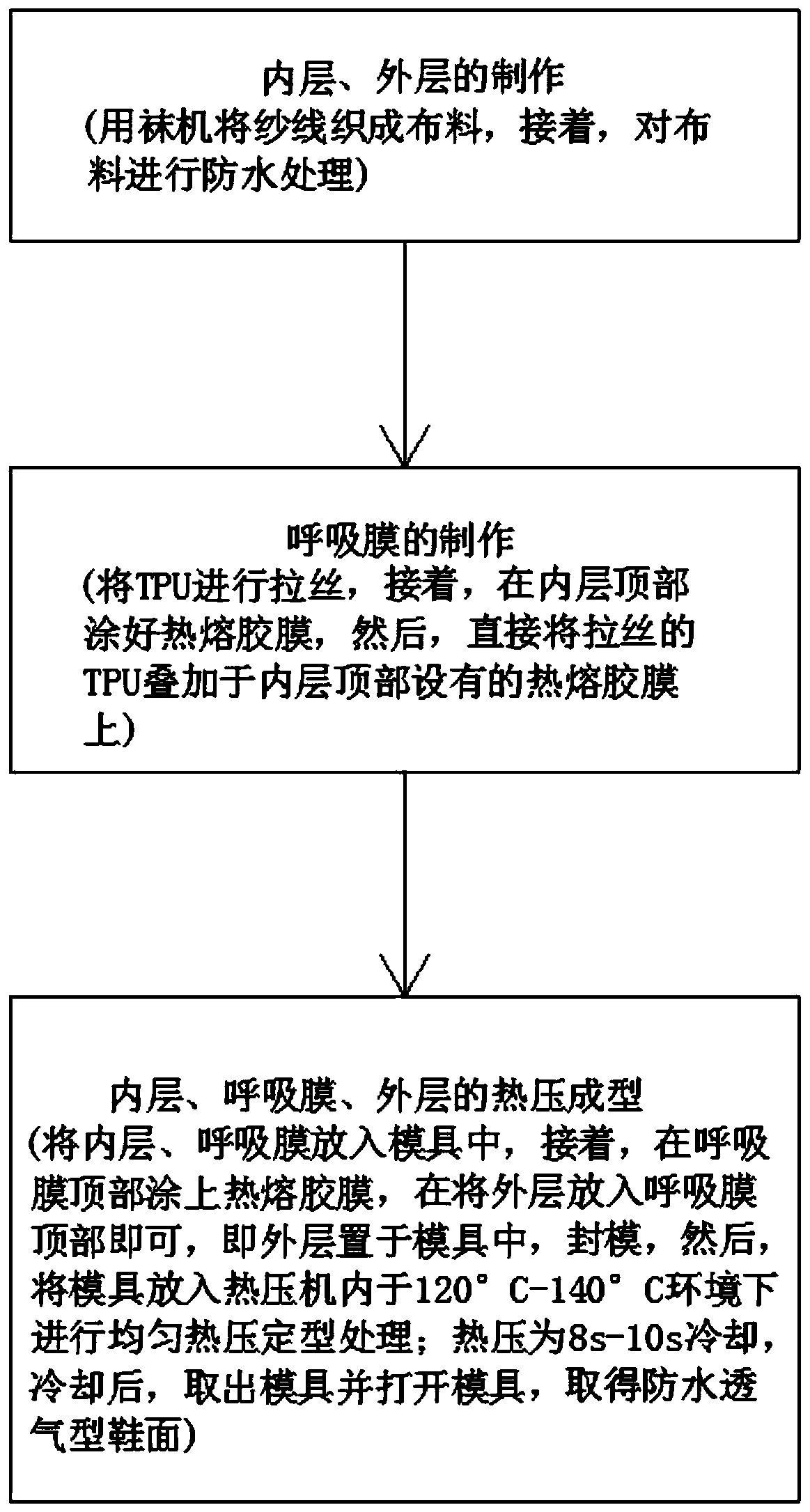

[0023] A waterproof and breathable upper such as Figure 1-2 As shown, it includes an inner layer 1, a breathing membrane 2 and an outer layer 3; the inner layer 1 and the outer layer 3 are all cloth, and the cloth is waterproof treated, and the top of the inner layer 1, the breathing membrane 2 The top is all provided with a hot melt adhesive film, the breathing film 2 is formed by drawing TPU and superimposed on the top of the inner layer 1, and the breathing film 2 is placed between the inner layer 1 and the outer layer 3 and is heated and pressed The inner layer 1 and the outer layer 3 have a pore diameter of 0.004mm-2mm; the hot pressing method is a uniform hot pressing method; the specific steps of the production process of the waterproof and breathable upper The steps are: S1: the production of the inner layer 1 and the outer layer 3; the yarn is woven into a cloth with a flat knitting machine, and then the cloth is waterproofed; S2: the production of the breathing memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap