Cleaning device free of raised dust

A technology for cleaning devices and dust collectors, which is applied in the direction of vacuum cleaners, cleaning equipment, suction nozzles, etc. It can solve the problems of inconvenient cleaning without dust, easy blockage of the filter, and small capacity of the ash tank, so as to ensure the safety of cleaning and reduce the workload. , strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

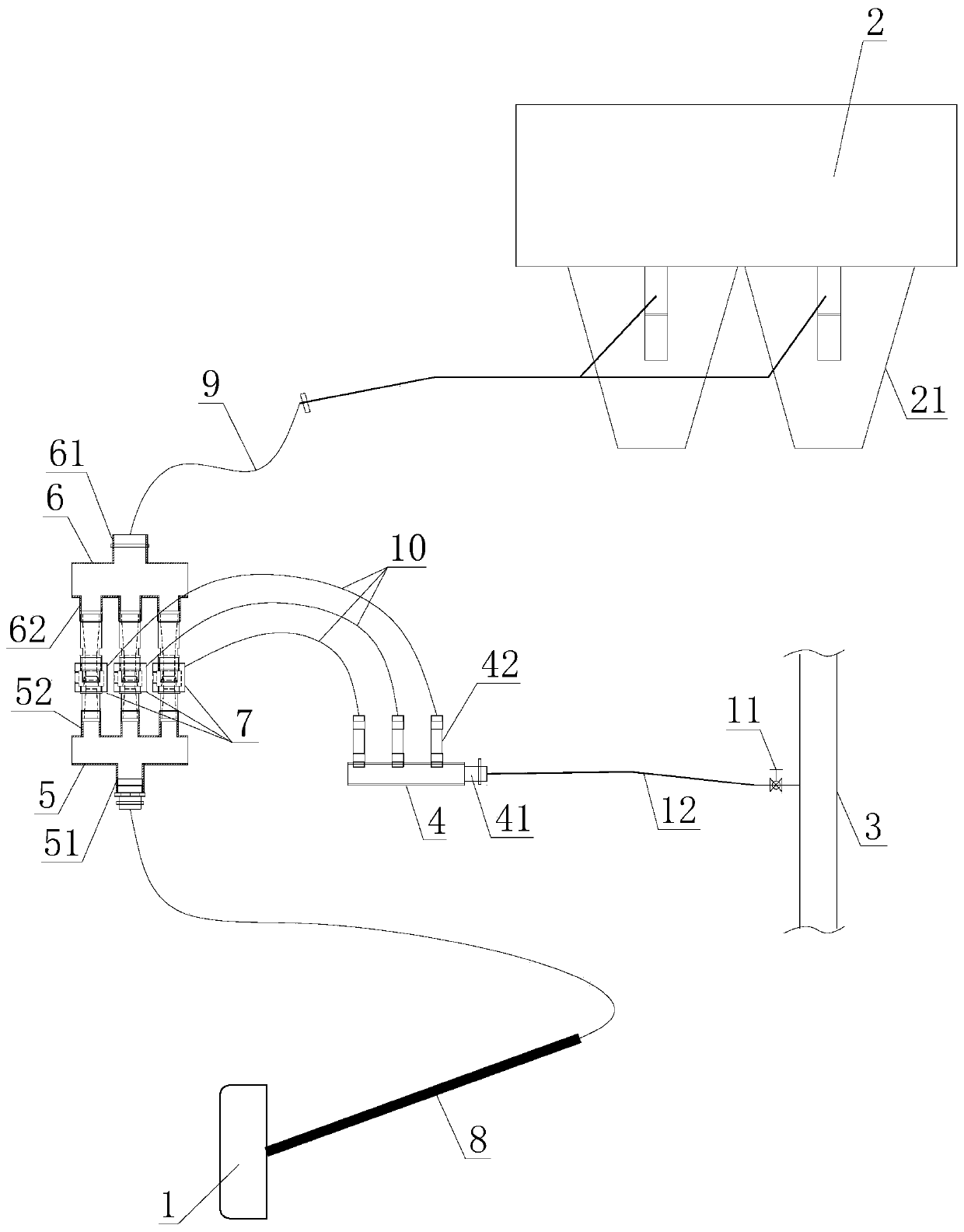

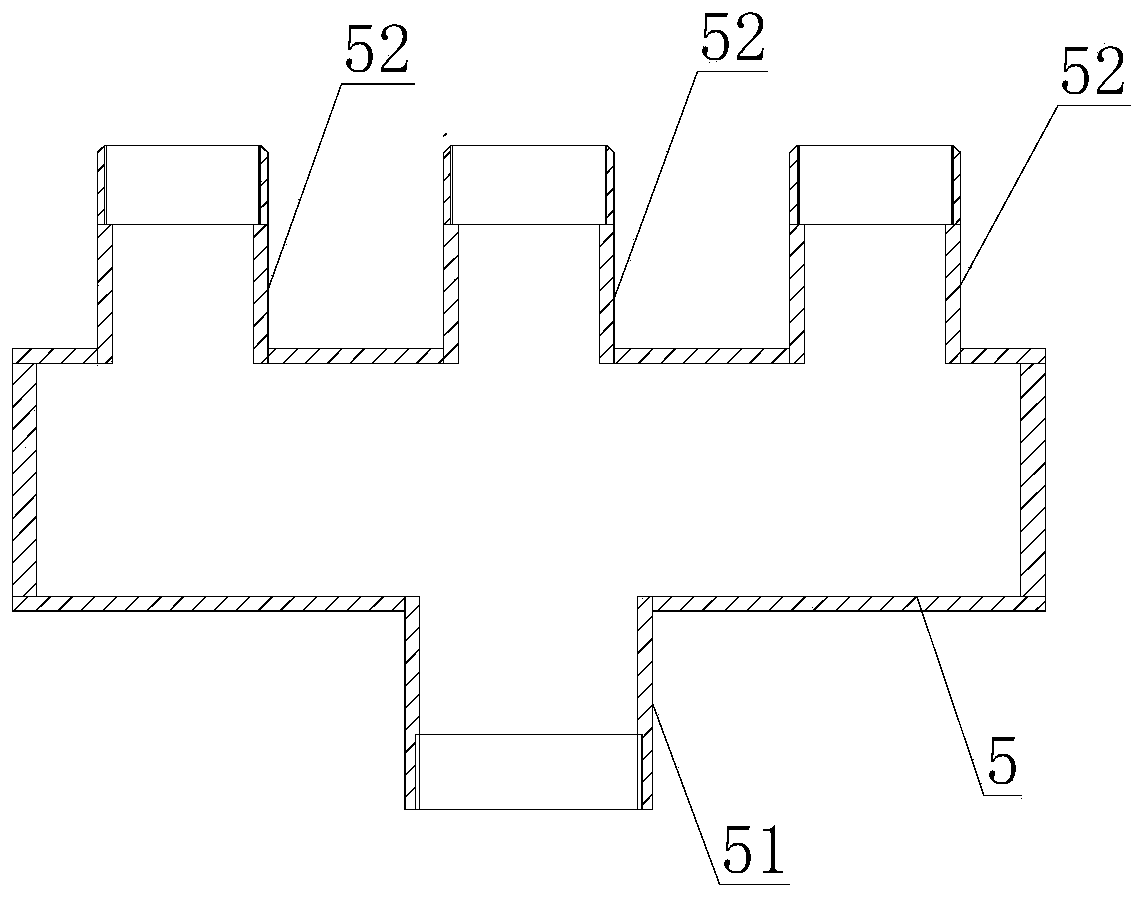

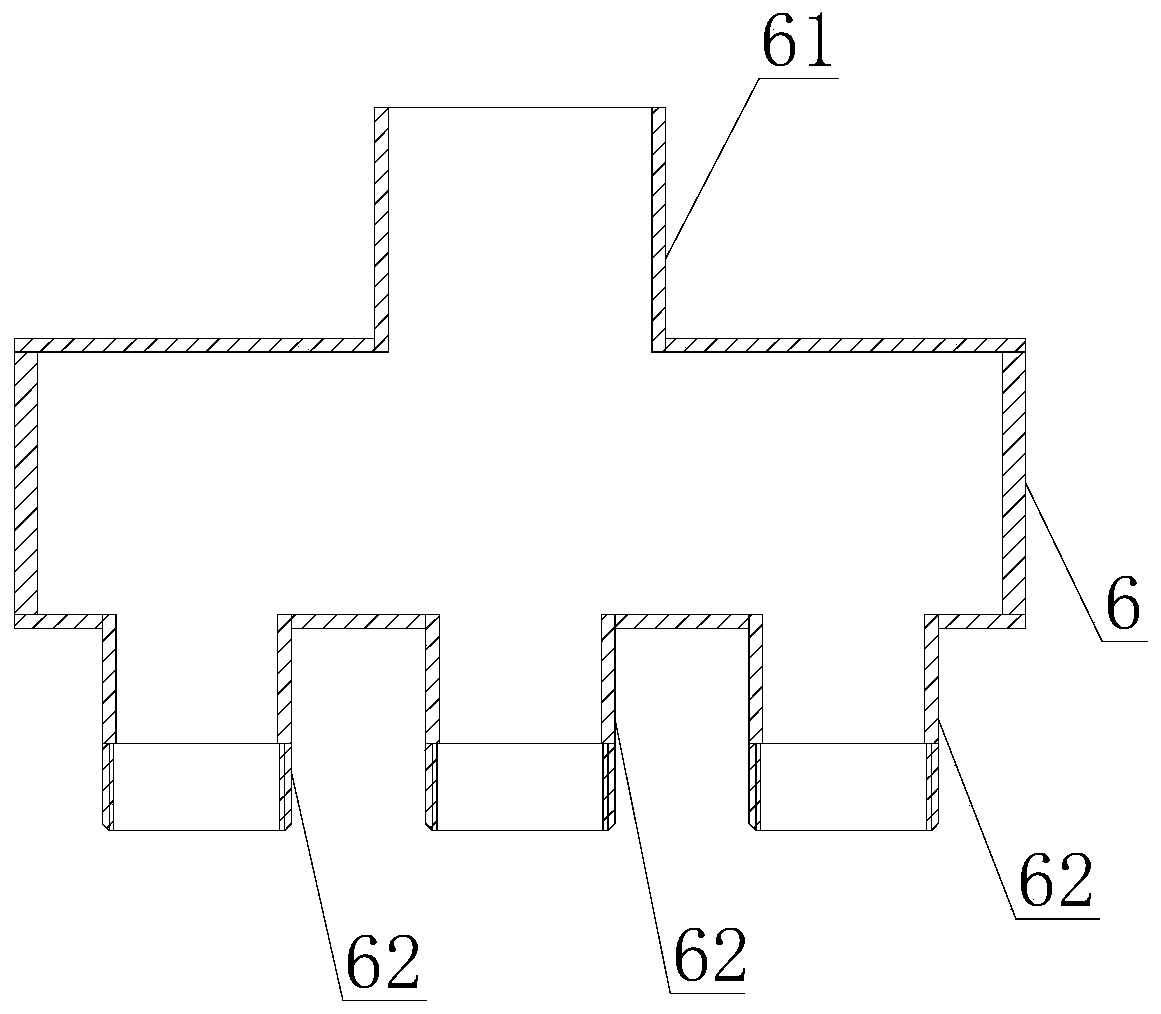

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the described dust-free cleaning device includes a dust suction floor brush 1, a dust collector 2, a compressed air source 3, a multi-ventilation source connector 4 with an inlet 42 and several outlets 42, and an inlet 51 And the multi-way inlet joint 5 of some outlets 52, and the multi-way outlet joint 6 with an outlet 61 and some inlets 62; the outlet 52 of the multi-way inlet joint 5 corresponds to the inlet 62 of the multi-way outlet joint 6, The outlet 52 of each pair of corresponding multi-way inlet joint 5 and the inlet 62 of the multi-way outlet joint 6 are respectively connected with a vacuum generator 7, and the outlet of the dust-absorbing ground brush 1 passes through the suction pipe 8 and the multi-way inlet joint 5. The inlet 51 is connected, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com