Automatic sorting line package loading system based on 3D (three-dimensional) vision and loading method thereof

An automatic sorting and three-dimensional vision technology, applied in sorting and other directions, can solve problems such as reduced work efficiency, increased labor costs, and high labor intensity of workers, and achieve the goals of solving high labor intensity, improving sorting efficiency, and saving labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

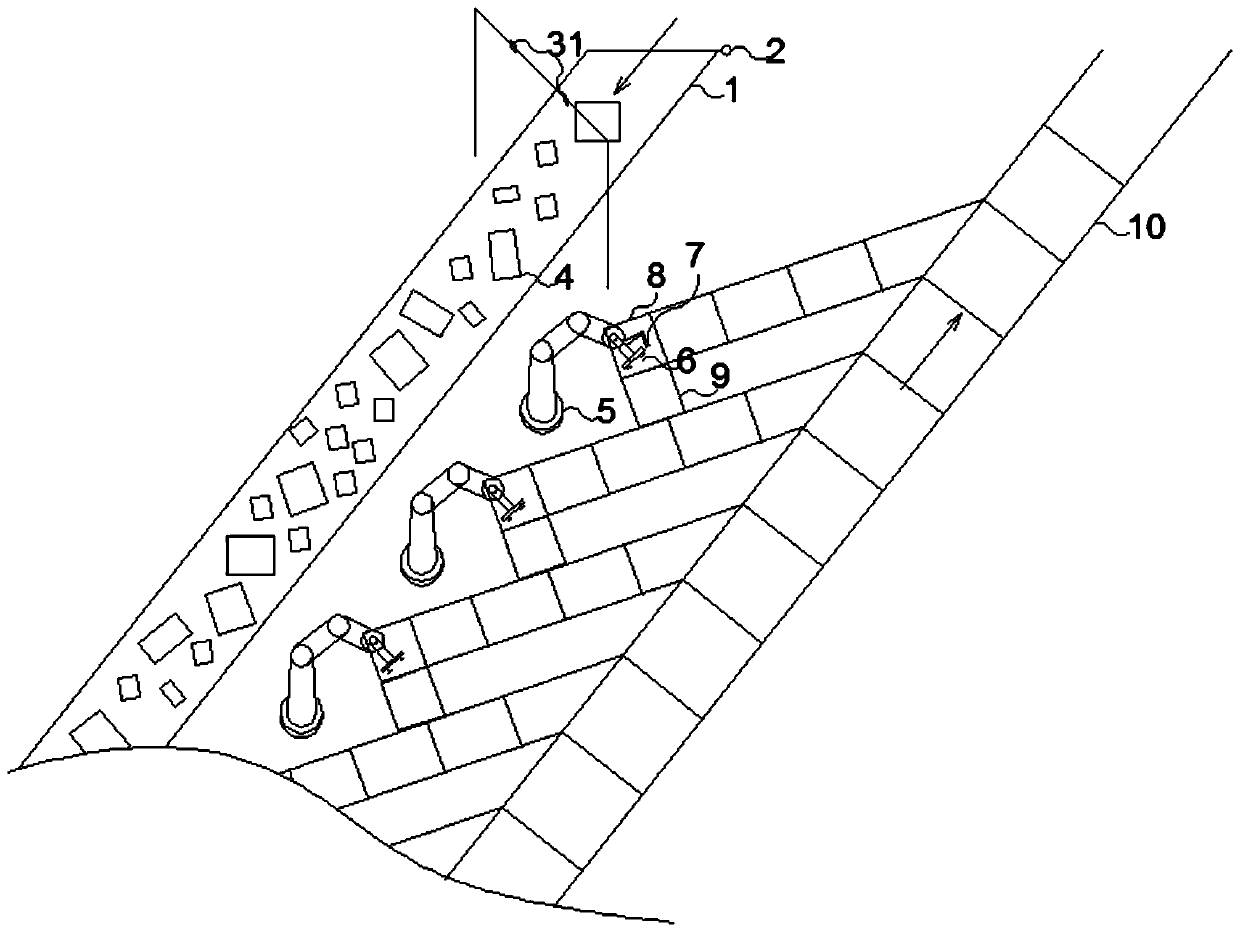

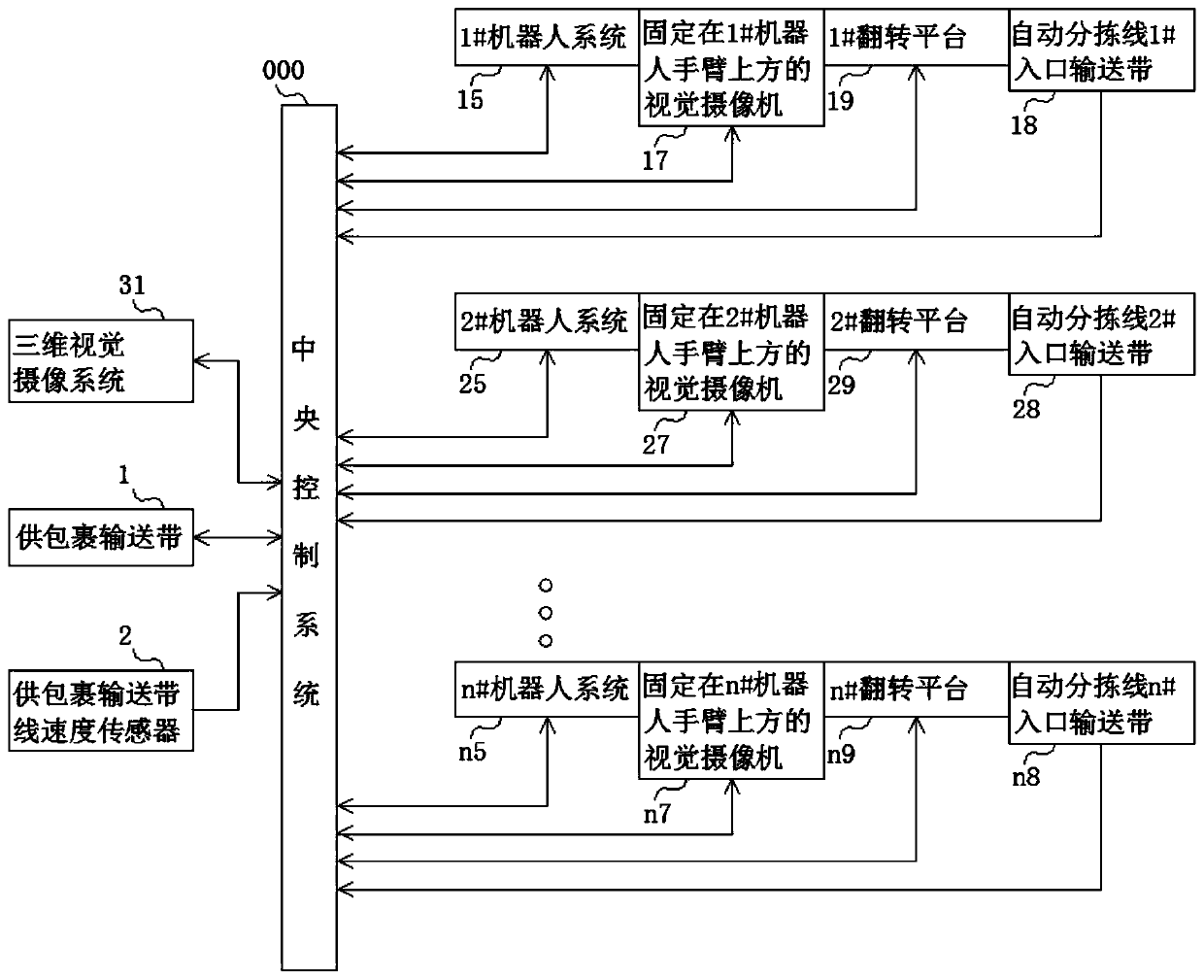

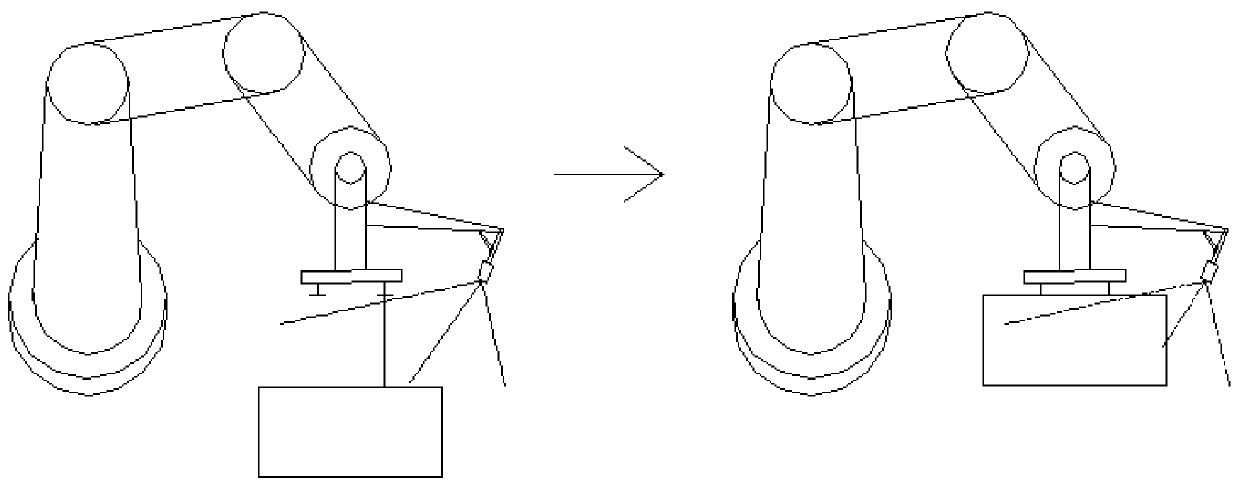

[0040] Such as figure 1 , figure 2 Shown: an automatic sorting line parcel loading system based on 3D vision, including a conveyor belt 1 for transporting parcels, an automatic sorting line is set on one side of the conveyor belt, and several parcel loading entrances are set on the automatic sorting line , the robot is arranged between the automatic sorting line and the conveyor belt; the input end of the conveyor belt is equipped with a three-dimensional vision camera system and a speed sensor, and the robot arm is equipped with a vision camera; through the three-dimensional vision camera system and the speed sensor for measuring the linear speed of the conveyor belt 2 At the same time, determine the position of each package on the conveyor belt and cooperate with the robot to realize the grabbing operation. The visual camera 7 fixed on the side of the robot arm, the robot puts the package with the label facing up into the automatic sorting through the visual camera 7 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com