Whole-row feeding and automatic material splitting device and method for strip-shaped permanent magnet block

A material distributing device and permanent magnet block technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as single function, inability to meet the automatic assembly system of strip permanent magnet blocks, and different application occasions. Achieve the effect of improving the degree of automation, simplifying the feeding and distributing line, and realizing accurate alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

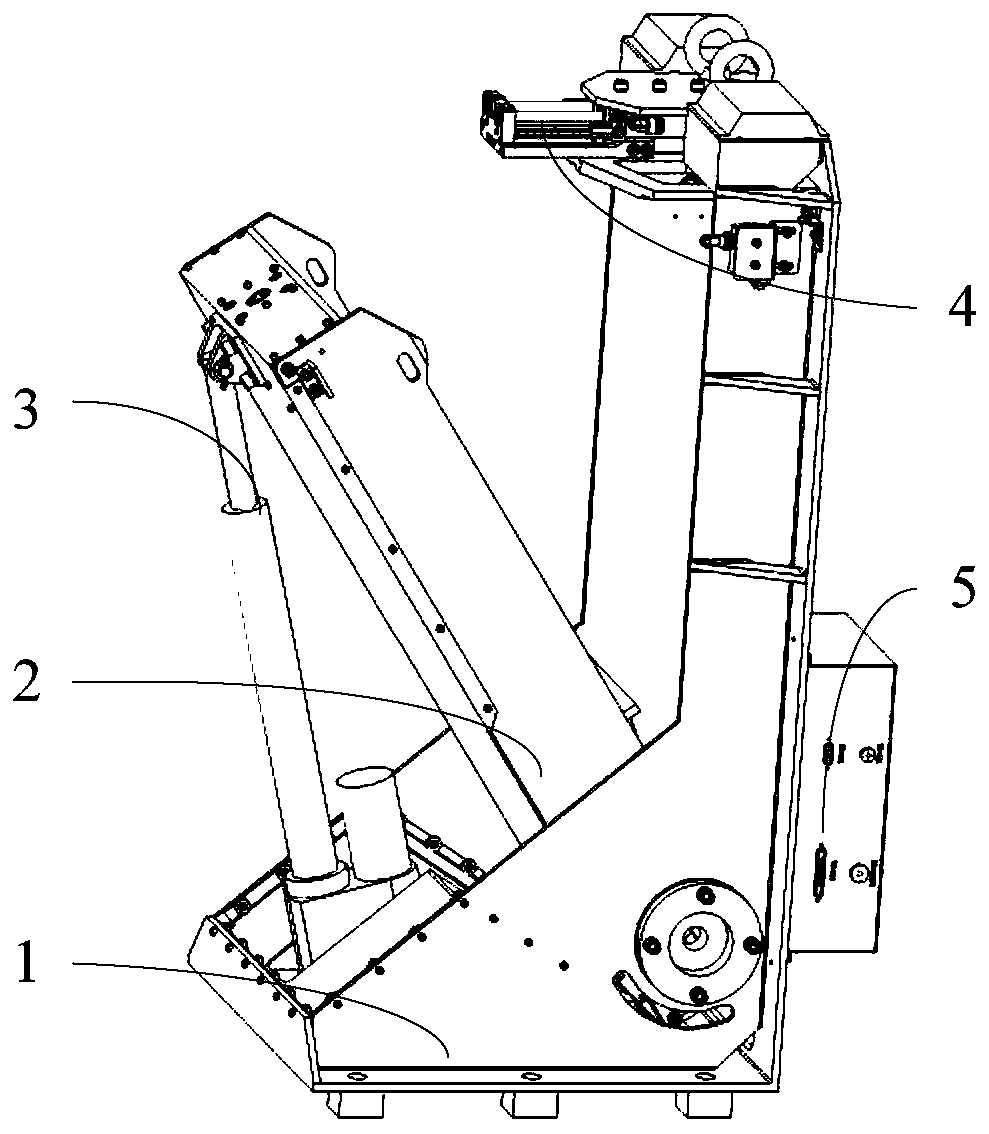

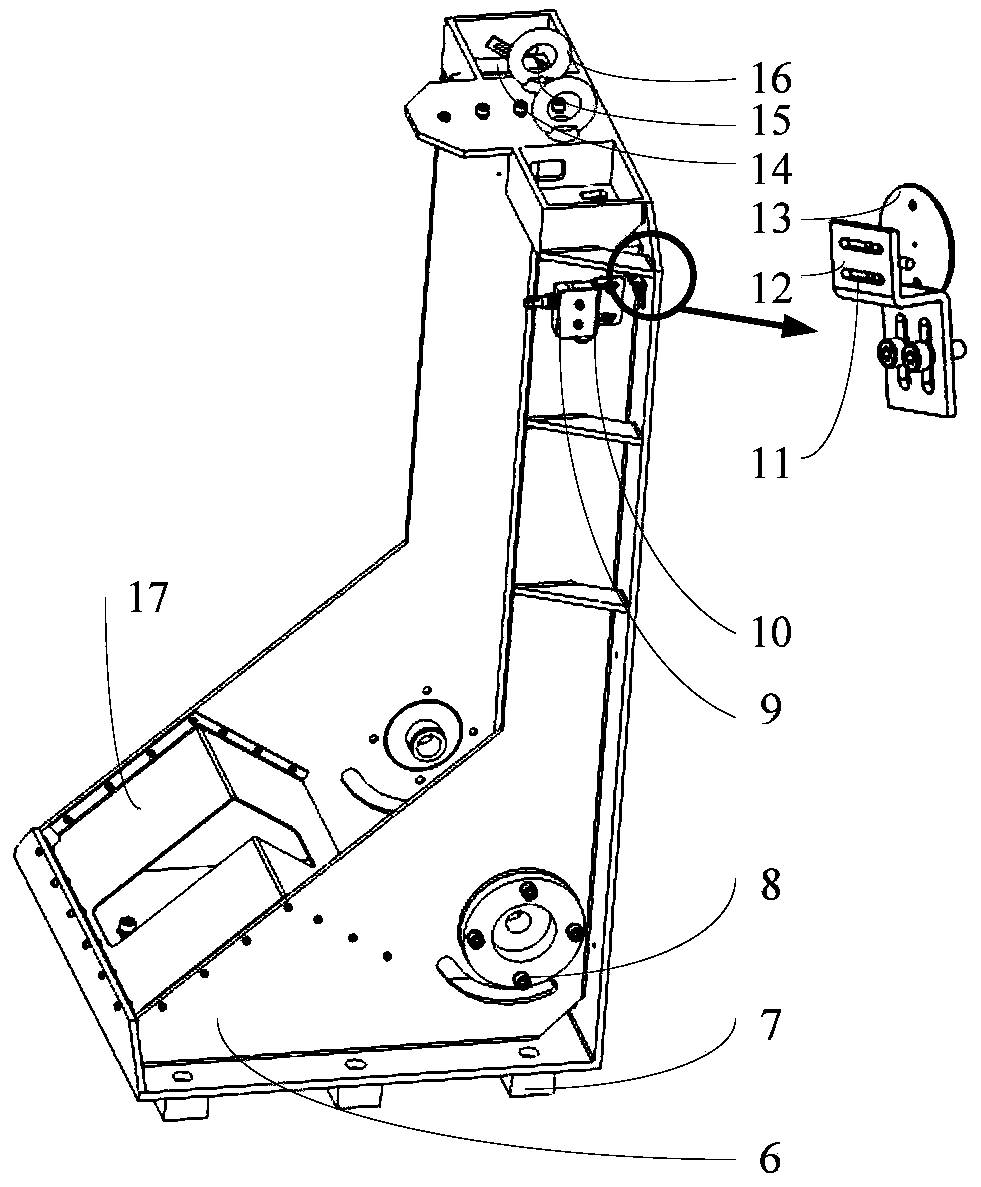

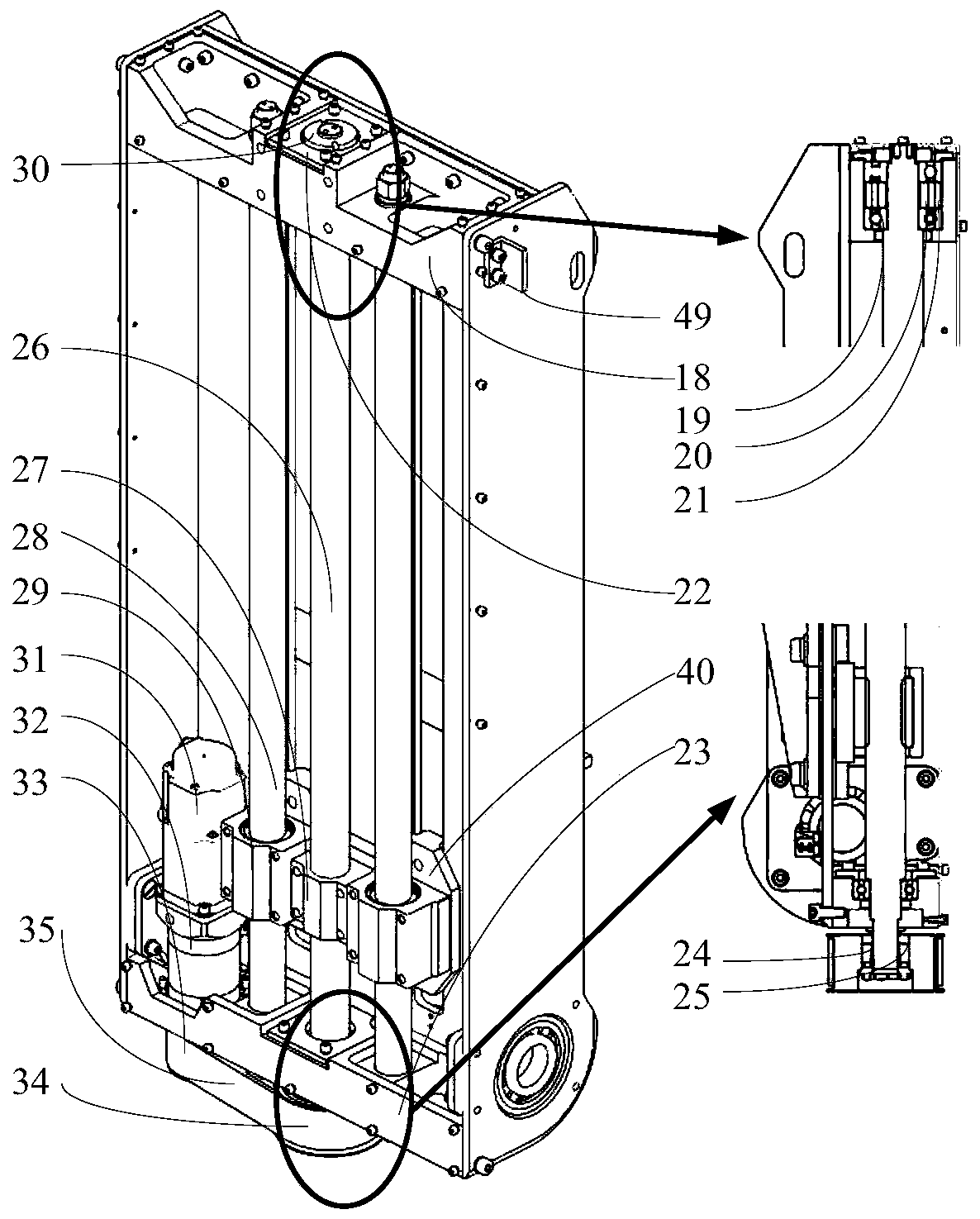

[0044] Figure 1 to Figure 7 It shows a specific embodiment of a row-shaped permanent magnet block feeding and automatic distributing device of the present invention, see figure 1 , the whole row of strip-shaped permanent magnetic block feeding and automatic feeding device includes: feeding base assembly 1, linear module 2, door opening and closing assembly 3, cutting assembly 4 and electronic control unit 5, wherein the feeding base assembly 1 is fixed to the ground by chemical bolts, the linear module 2 is hinged to the bottom of the feeding base assembly 1 through two cylindrical roller bearings 38, one end of the door opening and closing assembly 3 is fixed to the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com