High-precision indexing turntable for equal indexing drilling of outer circle of pipe parts and operation method

A technology for indexing turntables and pipe parts, applied in the field of pipe parts processing, can solve problems such as errors and affecting the processing quality of workpieces, and achieve the effect of ensuring reliability and facilitating the clamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

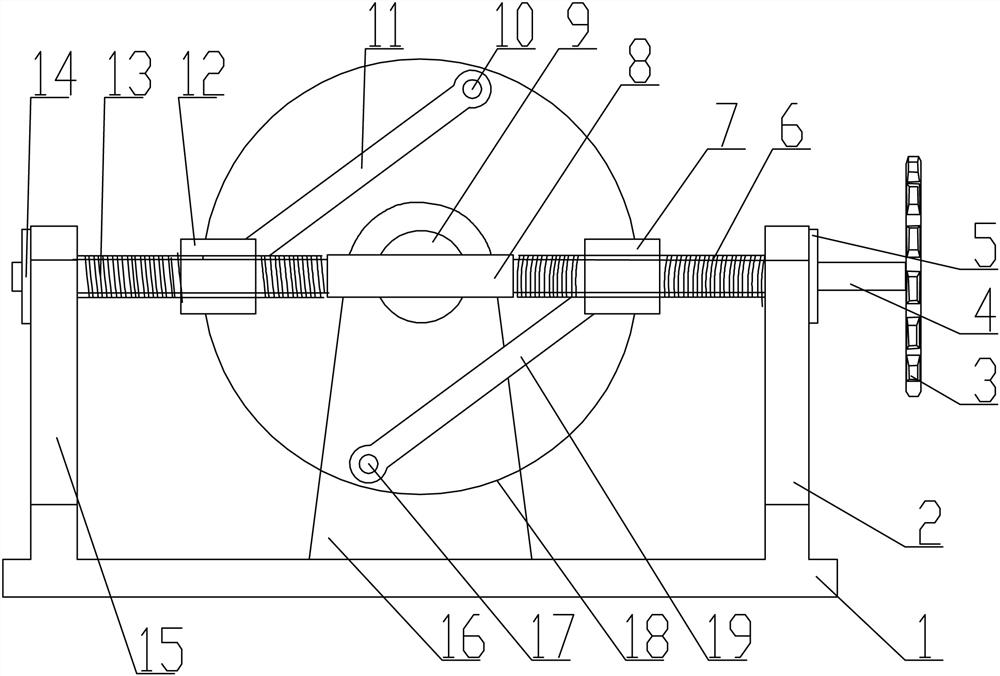

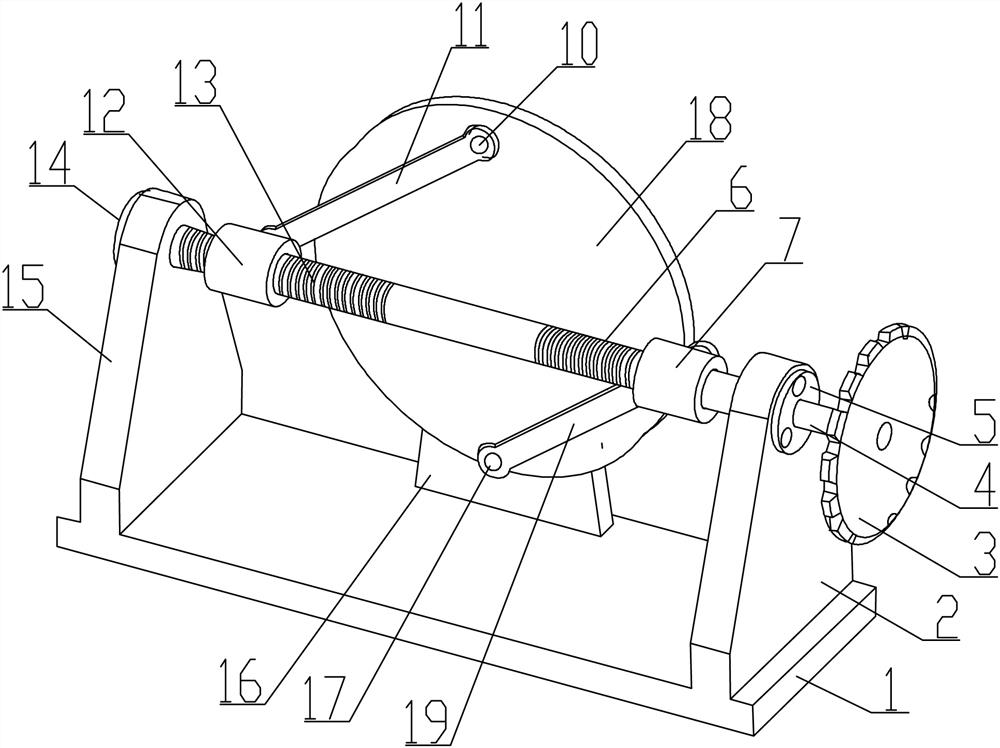

[0029] Such as Figure 1-2 As shown in the figure, the high-precision indexing turntable is used for the equi-indexed drilling of the outer circle of pipe parts. The top of the base 1 is fixedly installed with the first support plate 2 and the second support plate 15. The first support plate 2 and the second support plate A main shaft 4 is supported between the two support plates 15, and a first threaded section 6 and a second threaded section 13 are processed on the main shaft 4, and a first threaded sleeve 7 is mounted on the first threaded section 6 through thread transmission. , the second threaded segment 13 is fitted with a second threaded sleeve 12 through screw transmission, the side wall of the first threaded sleeve 7 is hinged with a first connecting rod 19, and the other end of the first connecting rod 19 Hinged on the side wall of the indexing turntable 18 by the first pin shaft 17, the second connecting rod 11 is hinged on the side wall of the second threaded slee...

Embodiment 2

[0037] The method for operating a high-precision indexing turntable used for the equal indexing drilling of outer circles of pipe parts is characterized in that it includes the following steps:

[0038] Step 1, clamping the pipe parts to be drilled to the three-jaw chuck fixture on the side wall of the indexing turntable 18;

[0039] Step 2, start the drilling equipment to drill the first hole on the outer wall of the pipe;

[0040] Step 3: After the drilling of the first hole is completed, drive the sprocket disc 3 to rotate through the chain transmission mechanism, and then the sprocket disc 3 drives the main shaft 4 to rotate, and the main shaft 4 synchronously drives the first thread segment 6 and the second The two threaded sections 13 rotate, and then the first threaded sleeve 7 and the second threaded sleeve 12 are synchronously driven by the first threaded section 6 and the second threaded section 13, and then the first threaded sleeve 7 and the second threaded sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com