A Control Method for Preventing Steel Strip Running Off

A control method, a technology of strip steel deviation, applied in heat treatment process control, manufacturing tools, furnaces, etc., can solve problems such as strip steel deviation, reduce temperature difference, avoid lateral temperature difference stress, and avoid deviation problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

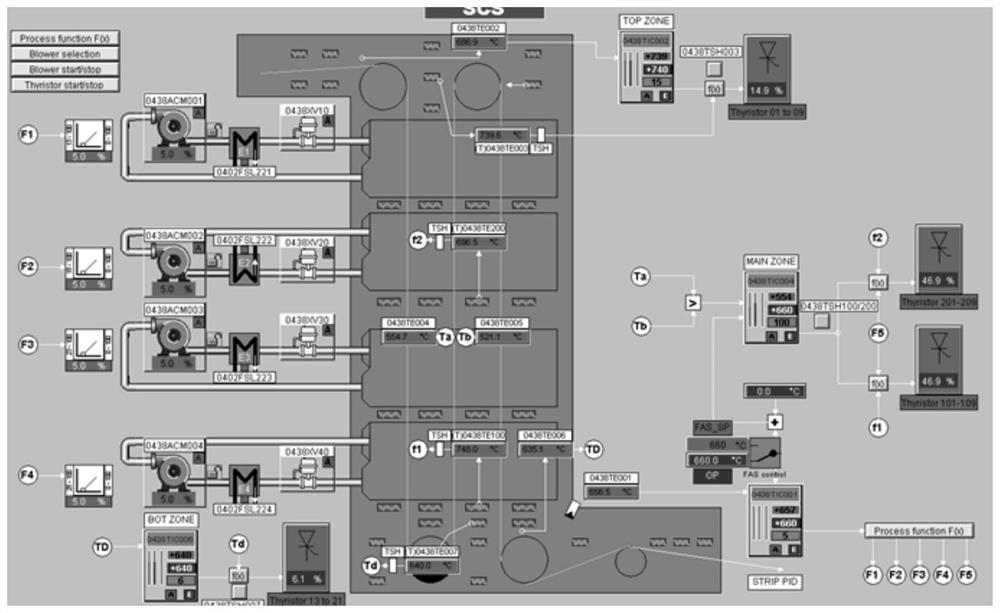

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention provide a control method for preventing strip deviation, which solves the technical problem of strip deviation in the prior art, and achieves the technical effect of preventing strip deviation.

[0037] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

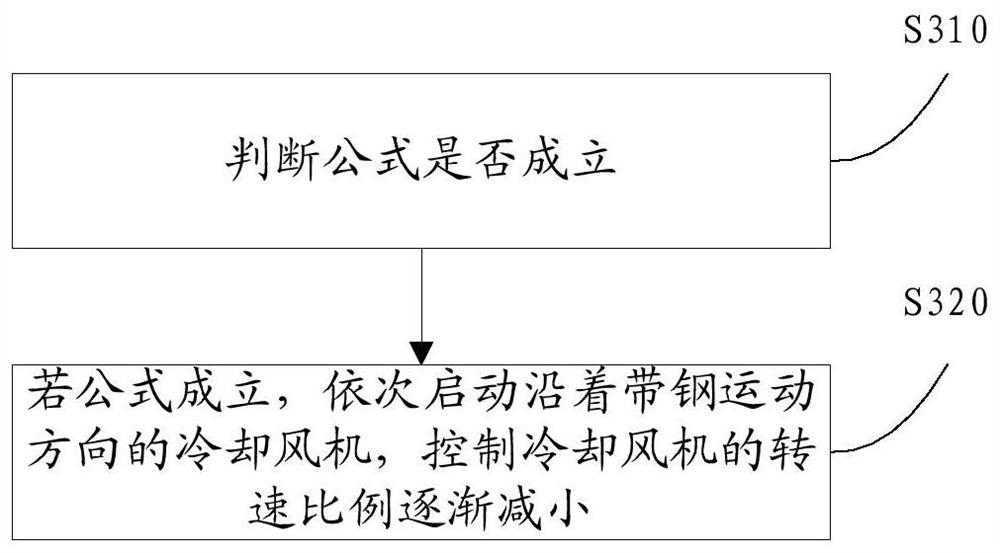

[0038] According to the maximum thickness and the thinnest thickness of the strip steel in the furnace designed by the unit, the critical thickness of the strip steel deviation in the cooling section is obtained, and this thickness is used as the activation condition of the control, thereby starting the cooling fan along the moving direction of the strip steel, Control the speed ratio of the cooling fan to gradually increase. With the gradual increase of the speed ratio of the cooling fan, it means that the flow rate of the cooling gas at the bottom of the annealing furnace for heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com