Cooling device for hot-rolled steel strip

A technology of cooling device and steel strip, which is applied in the direction of workpiece cooling device, quenching device, guiding/positioning/aligning device, etc., can solve the problems of high cost, no installation, large-scale device, etc., and achieve low cost and high manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

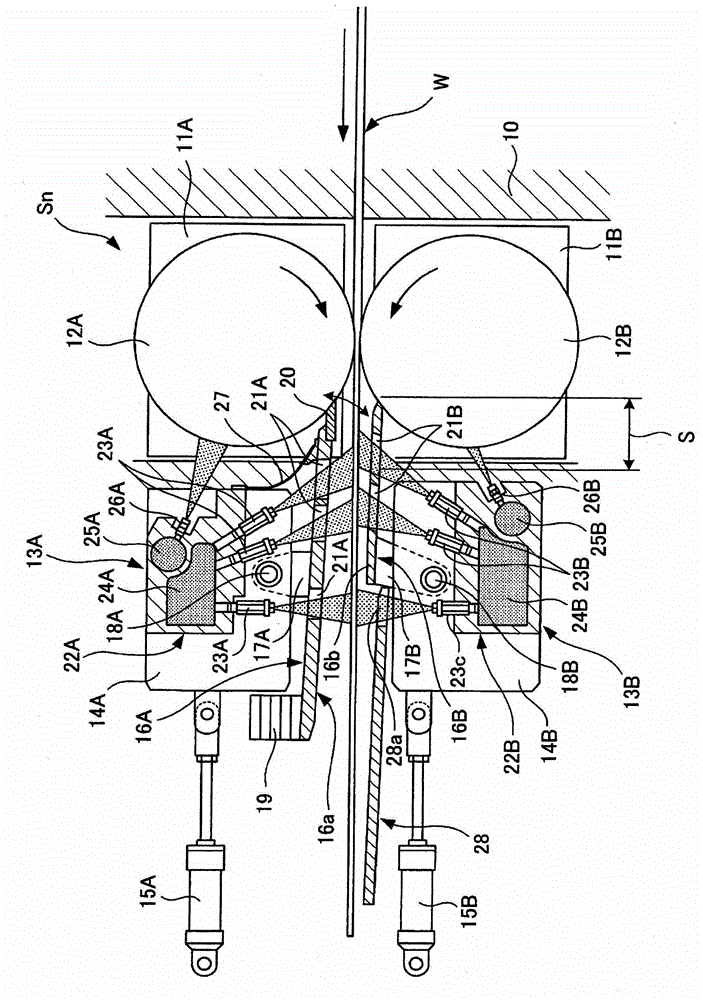

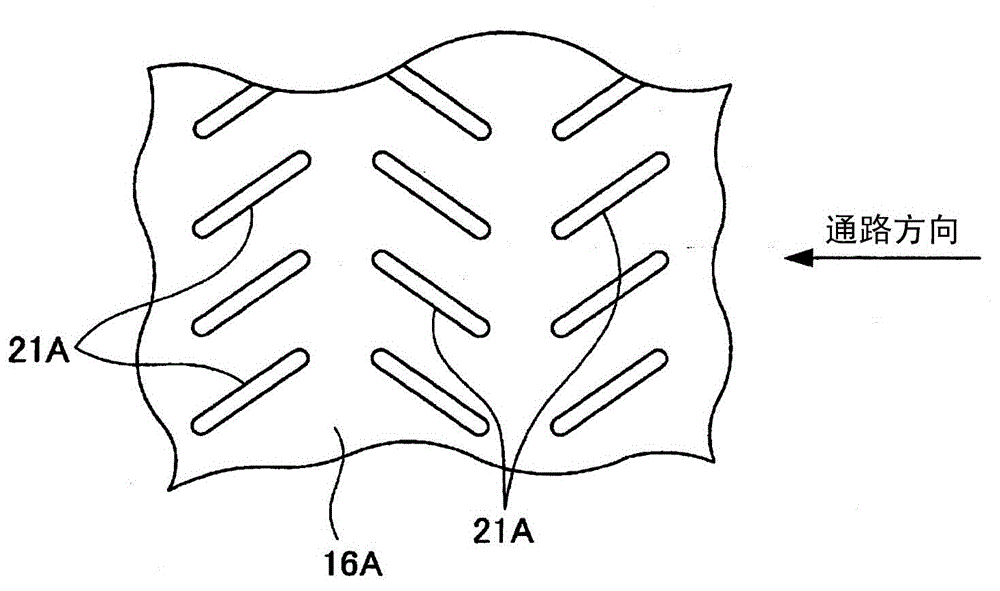

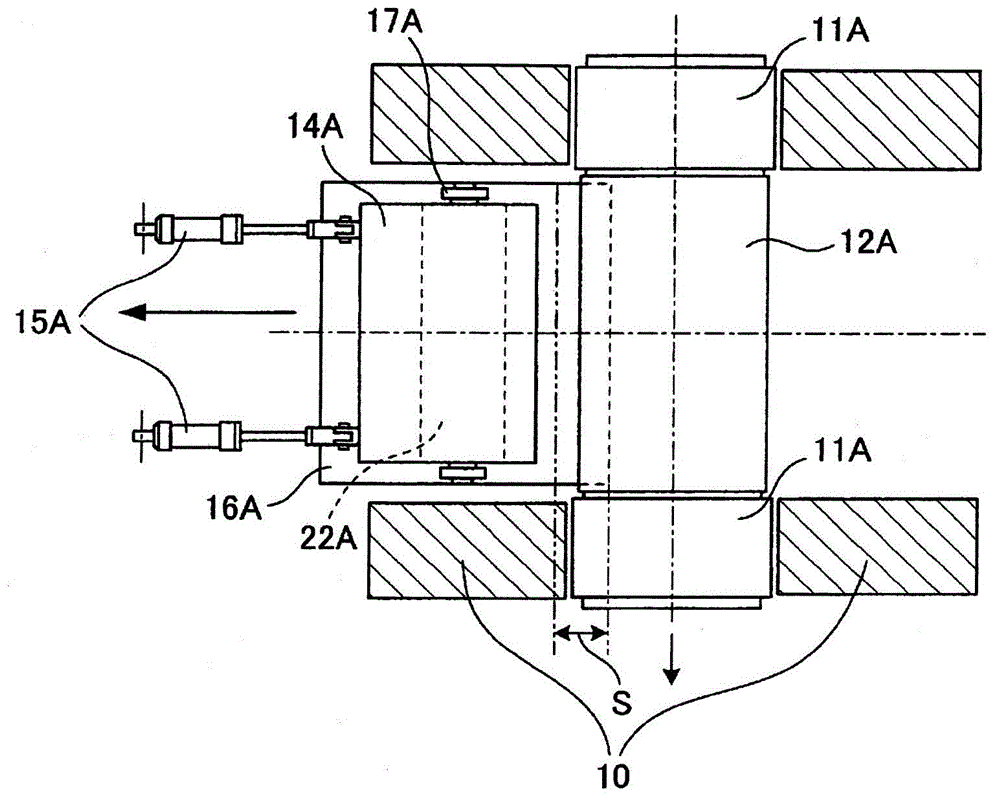

[0055] figure 1 is a side sectional view showing a cooling device for a hot-rolled steel strip according to Embodiment 1 of the present invention, figure 2 is the top view of the upper guide, Figure 3A is a plan view of the upper guide during rolling, Figure 3B It is a plan view when the roller of the upper guide is replaced.

[0056] Such as figure 1 As shown, in the final stand Sn on the finishing mill row of the hot rolling equipment, the upper cooling device 13A and the upper cooling device 13A and The lower cooling device 13B, the upper work roll 12A is rotatably supported with respect to the casing 10 via a pair of left and right upper work roll chucks 11A via a motor not shown, and the lower work roll 12B is similarly provided via a pair of left and right The lower work roll chuck 11B is rotatably supported with respect to the housing 10 by a motor not shown.

[0057] In addition, as described later Figure 3B As shown, the upper and lower work rolls 12A, 12B a...

Embodiment 2

[0085] Figure 4 is a side sectional view showing a cooling device for a hot-rolled steel strip according to Example 2 of the present invention, Figure 5A is the top view of non-cross rolling, Figure 5B It is a plan view at the time of cross rolling.

[0086] This is an example in which the upper and lower cooling devices 13A and 13B in the first embodiment are applied to a cross rolling mill in which the upper and lower work rolls 12A and 12B intersect in the direction in which the rolled product W is conveyed.

[0087] Specifically, a pair of left and right hydraulic cylinders 15A, 15B above and below the rolled material W are pin-coupled to the nozzle blocks 14A, 14B and the casing 10 so that they can rotate horizontally at the front end of the piston rod and the base end of the head. , and spacers 30A, 30B abutting against the upper and lower workpiece roll chucks 11A, 11B are attached to the left and right front sides of the nozzle blocks 14A, 14B via brackets 29 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com