Intelligent dyeing equipment for rainbow lines

A rainbow and equipment technology, which is applied to the processing of textile materials, equipment configuration, textiles and papermaking, and removal of liquid/gas/steam, etc. It can solve the problems of affecting the dyeing effect, the transition part is not natural, and the dyeing efficiency is low. Improve dyeing efficiency, natural color transition, and prevent decolorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

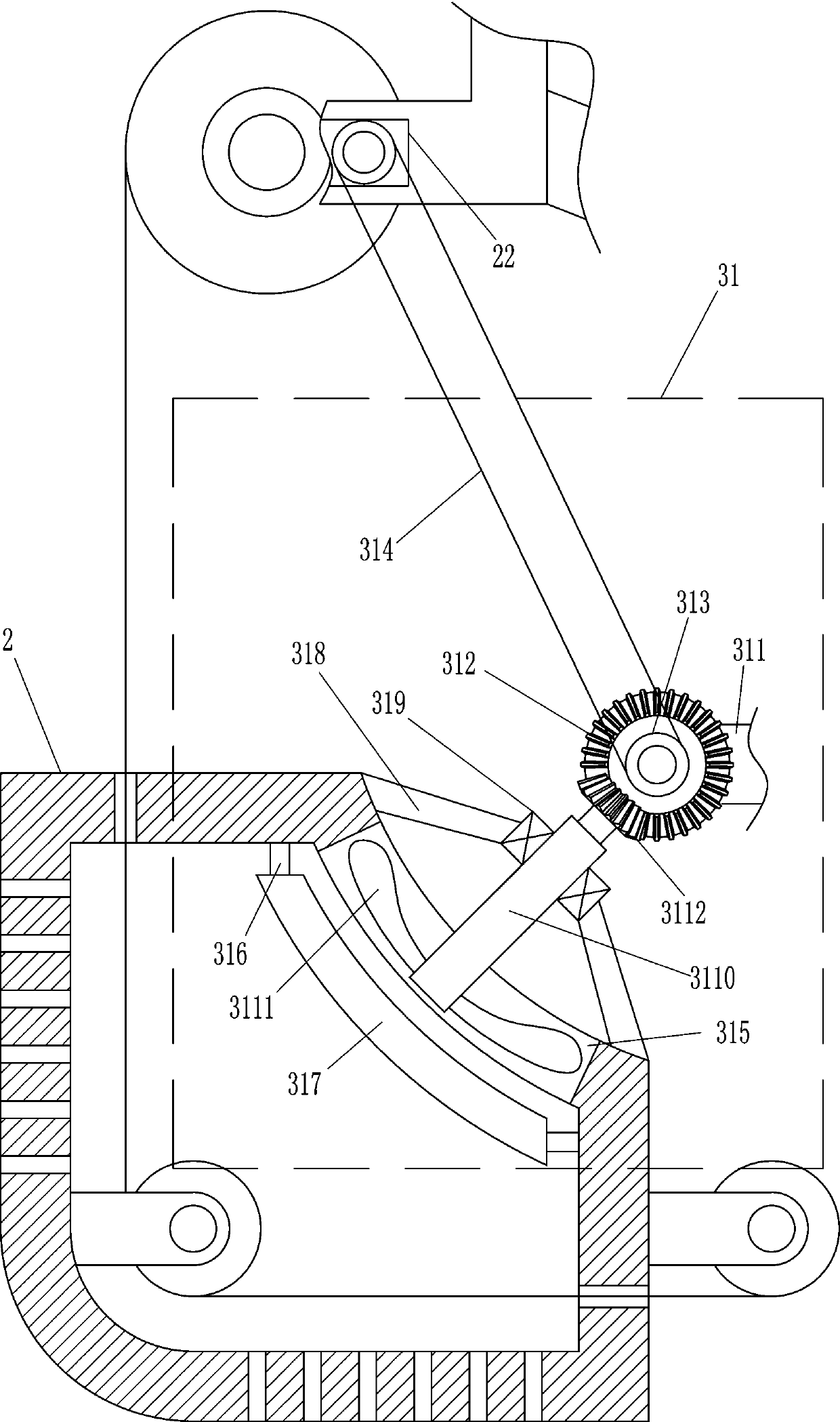

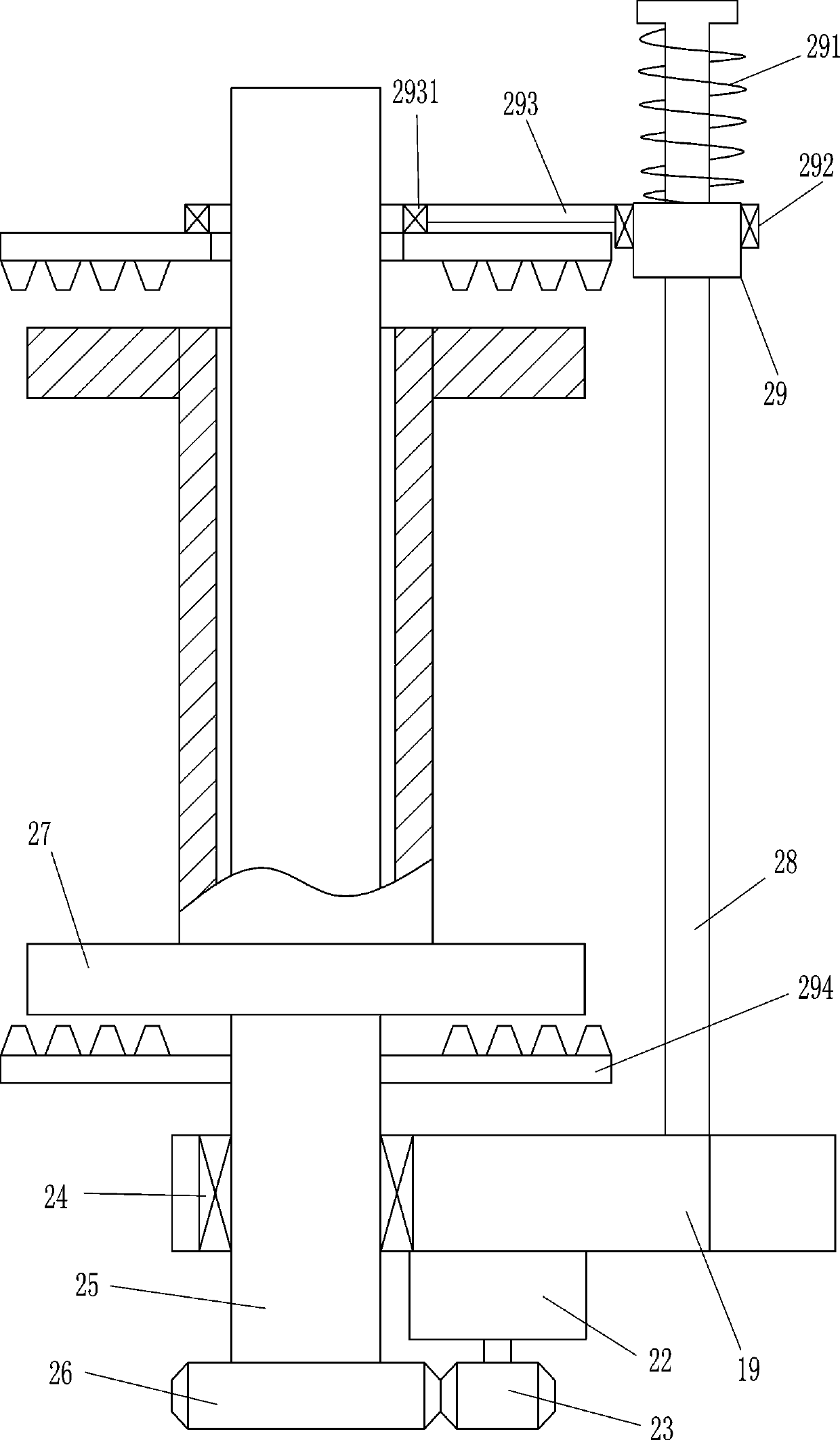

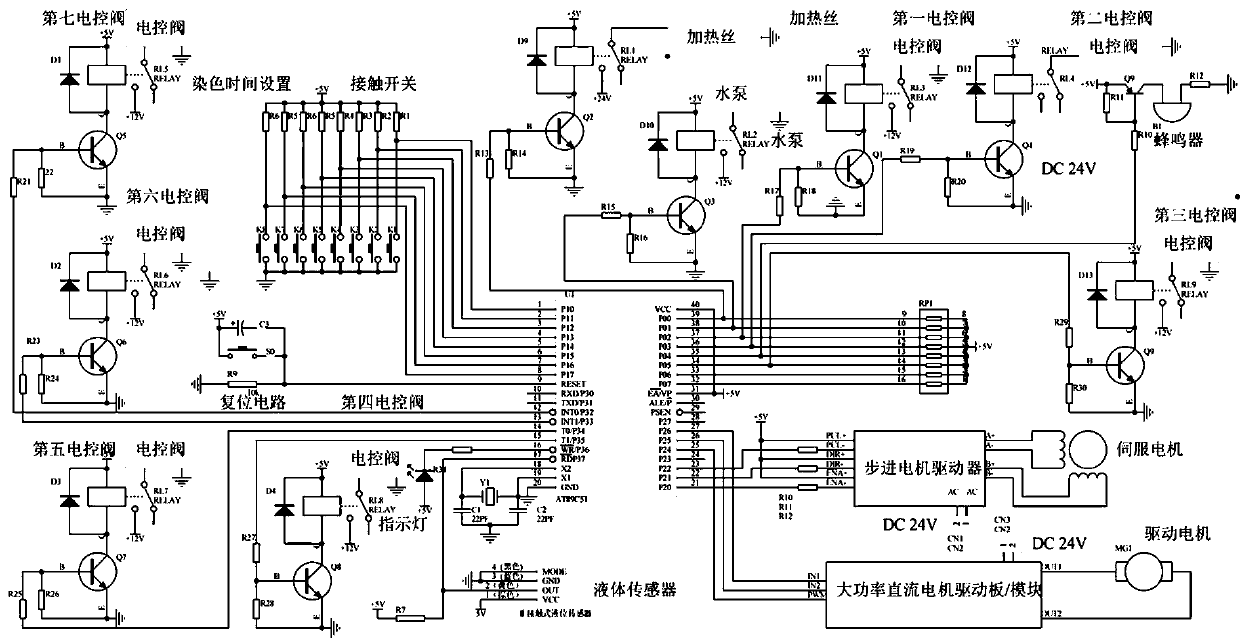

[0024] A rainbow thread intelligent dyeing equipment, such as figure 1 , figure 2 , Figure 7 and Figure 8As shown, it includes a bottom plate 1, a drying box 2, a first pulley 5, a second pulley 6, a first pole 7, a second pole 8, a connecting plate 10, a feeding pipe 11, a water pump 12, and a filling pipe 13. Liquid storage joint 14, spray head 15, third pulley 16, inclined rod 18, L-shaped plate 19, wire sleeve 20, fourth pulley 21, drive motor 22, first gear 23, first bearing seat 24, second One rotating rod 25, the second gear 26, the bobbin 27, the guide rail 28, the guide sleeve 29, the spring 291, the second bearing seat 292, the fixed rod 293, the third bearing seat 2931, the splint 294, the control box 101, the power supply assembly Switch 102, intelligent blanking device 30 and drying device 31, a drying box 2 is provided on the left side of the top of the bottom plate 1, and a first through hole 3 is opened on the left part of the upper wall of the drying box...

Embodiment 2

[0031] On the basis of Example 1, such as Figure 5 As shown, it also includes a closed box 321, a sealing ring 322, a waste liquid pipe 324, a placement plate 325 and a collection box 326, a closed box 321 is arranged between the first pole 7 and the top of the second pole 8, and the liquid storage joint 14 and the spray head 15 are located in the closed box 321, the middle part of the left and right walls of the closed box 321 has a fourth through hole 323, the fourth through hole 323 communicates with the third through hole 17, embedded in the middle of the closed box 321 upper wall A sealing ring 322 is provided, the filling pipe 13 passes through the sealing ring 322, a waste liquid pipe 324 is connected in the middle of the lower wall of the closed box 321, and a placement plate 325 is arranged between the first pole 7 and the upper part of the second pole 8, and the The plate 325 is located under the closed box 321 , and the collecting box 326 is placed on the placing p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap