A track mooring system for docks

A track and mooring technology, applied in shipping equipment, ships, etc., can solve the problems of uneven force on the mooring cable, difficult to adjust, and cable grinding, and achieve the effect of improving the force characteristics and optimizing the force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

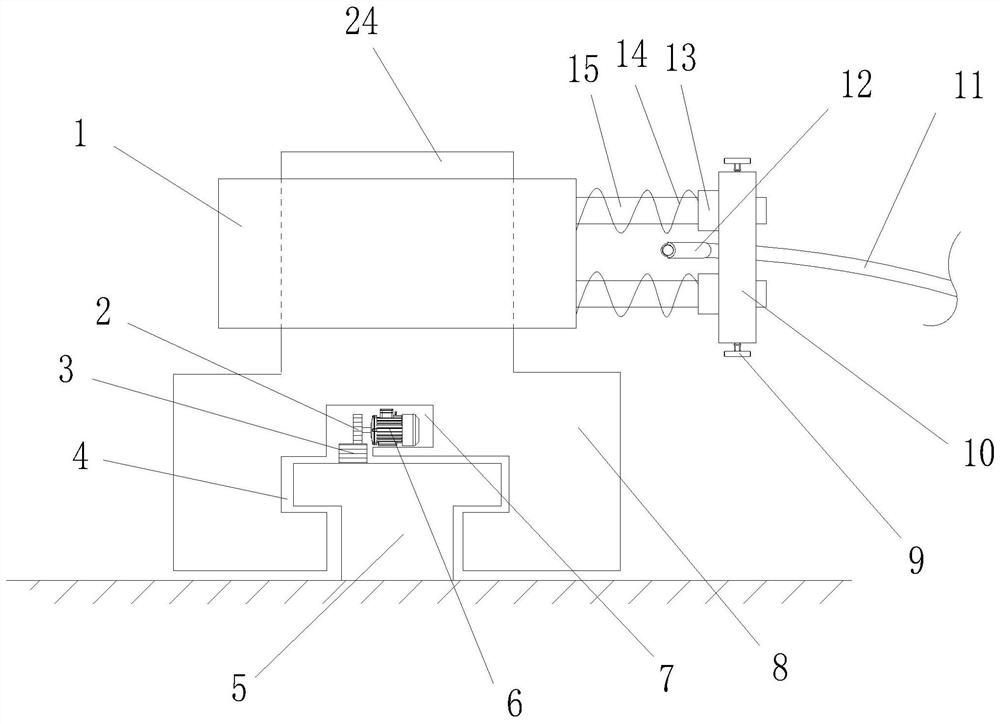

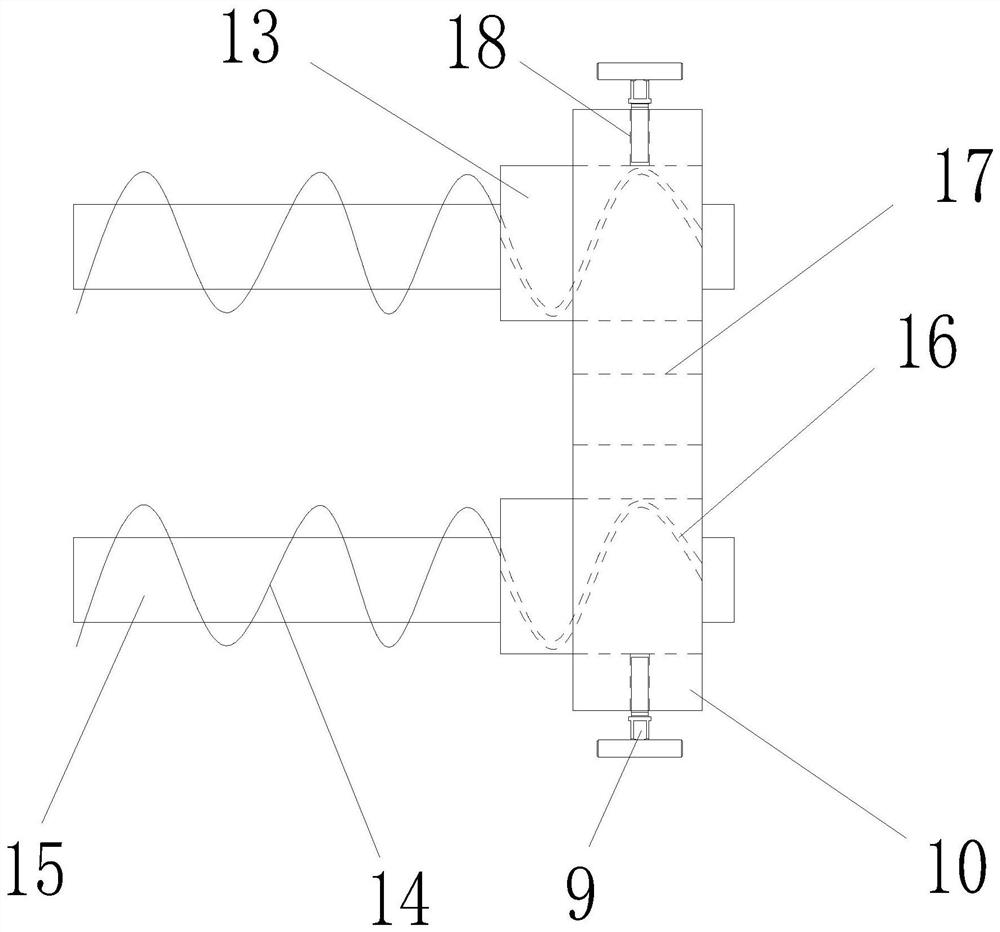

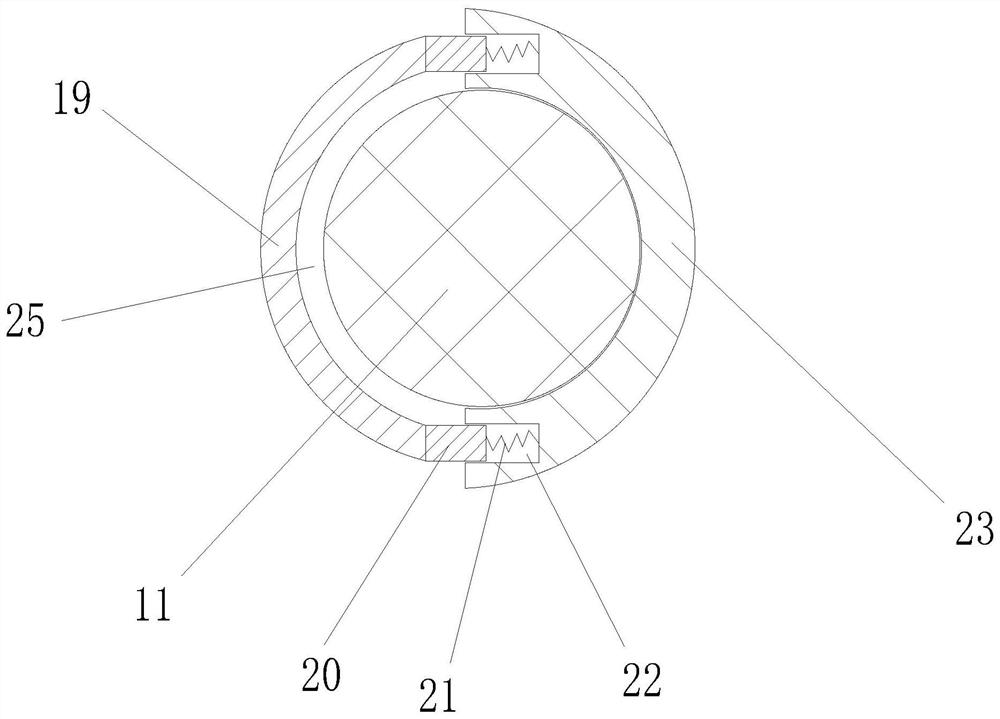

[0027] Such as figure 1 , 2 As shown, a rail mooring system for a dock includes a rail 5 installed on the front edge of the dock, a slider 8 is slidably connected to the rail 5, and a chute 4 matching the rail 5 is arranged inside the slider 8. The slider 8 The number is multiple, the cross section of the track 5 is T-shaped, the shape of the chute 4 matches the shape of the track 5, which improves the stability of the slider 8 when sliding on the track 5, and the top of the chute 4 is set There is an inner chamber 7 located in the slider 8, a translation motor 6 is arranged on the side wall of the inner chamber 7, a rack 3 is arranged on the track 5, and a gear 2 for meshing with the rack 3 is connected to the output shaft of the translation motor 6 , when the translation motor 6 is started, it can drive the slider 8 to move to a suitable position along the track 5 on the rack 3, the translation motor 6 is controlled by the information control system, and when the mooring sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com