Compound prefabricated shear wall for assembled building

A prefabricated shear force, composite technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of insufficient grouting, failure to meet the design anchor strength requirements, poor overall stability, etc., to reduce investment and save painting. Mortar layer, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

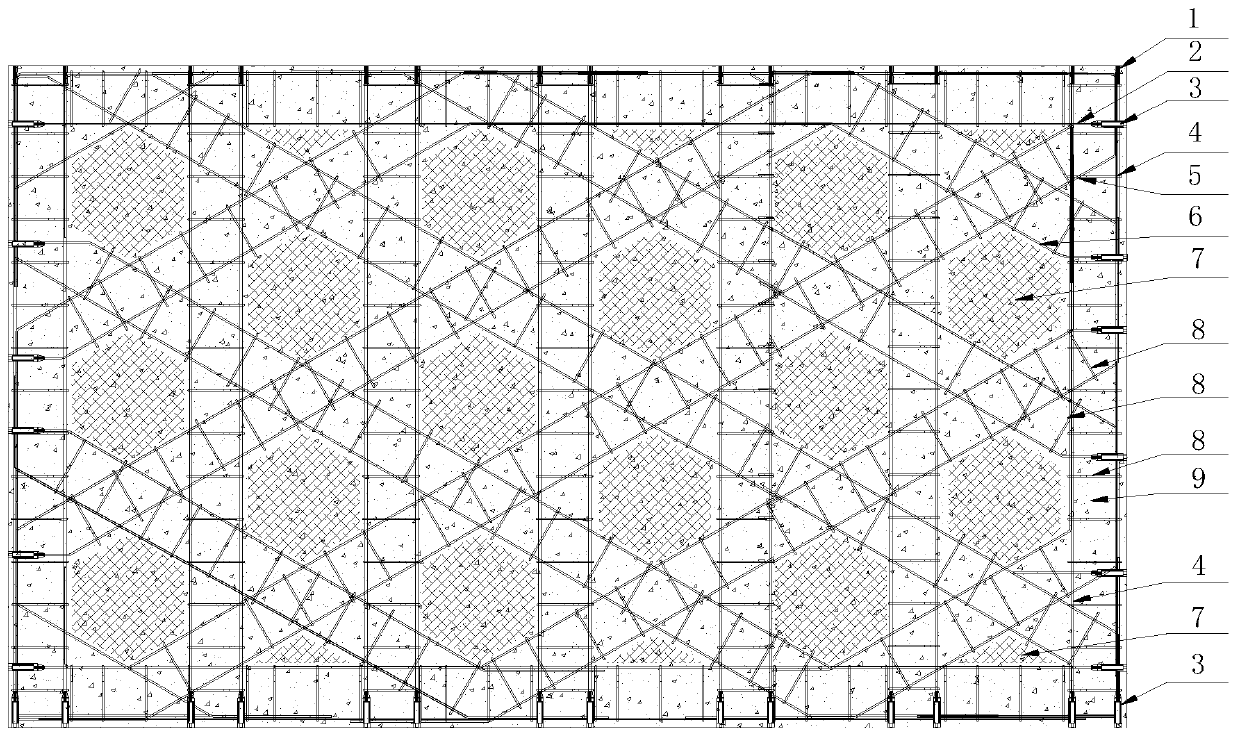

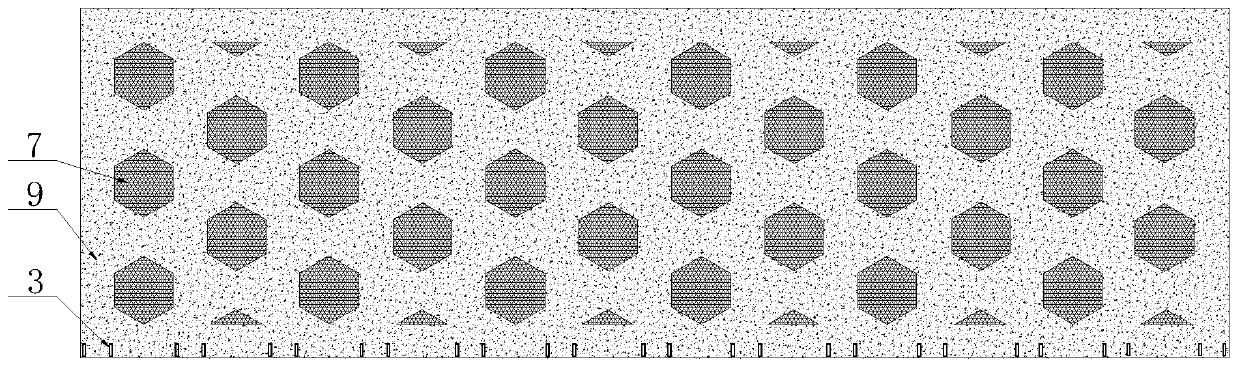

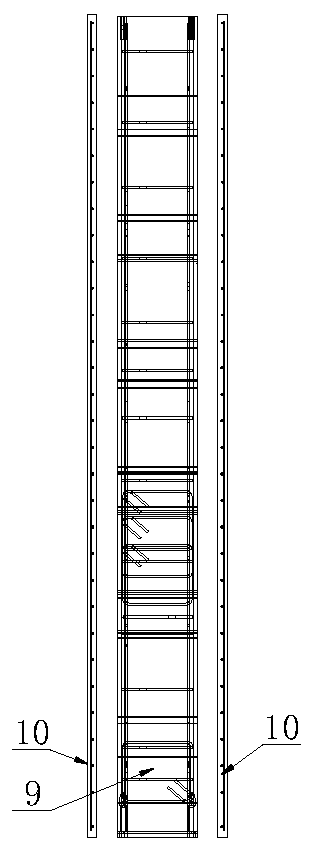

[0021] from Figure 1-3 It can be seen that a composite prefabricated shear wall for prefabricated buildings in this embodiment includes filled concrete 9, horizontal anchor bars 2 and vertical steel bars 4, and walls are symmetrically arranged on both sides of the filled concrete 9 surface. The surface reinforcement mesh 10, the wall reinforcement mesh 10 is made of small-diameter steel bars or welded, the upper end of the vertical reinforcement 4 is processed into a thread shape, and the vertical reinforcement 4 is threaded with the straight threaded reinforcement connecting sleeve 1. Structural stirrups 8 are arranged between the adjacent vertical steel bars 4, and the vertical steel bars 4 and the structural stirrup bars 8 are fixedly bound. A structural stirrup 8 is arranged between the horizontal anchor bars 2, and the horizontal anchor bars 2 and the structural stirrups 8 are fixedly bound. Both ends are connected with U-shaped steel bar connecting sleeve 3. The straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com