A kind of fire pipe fitting and its installation method

A technology for pipe fittings and fire protection, which is applied in the direction of pipe components, pipes/pipe joints/fittings, passing elements, etc., which can solve the problems of fire pipe impact, high maintenance costs, water leakage, etc., to improve anti-vibration performance, ensure sealing performance, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

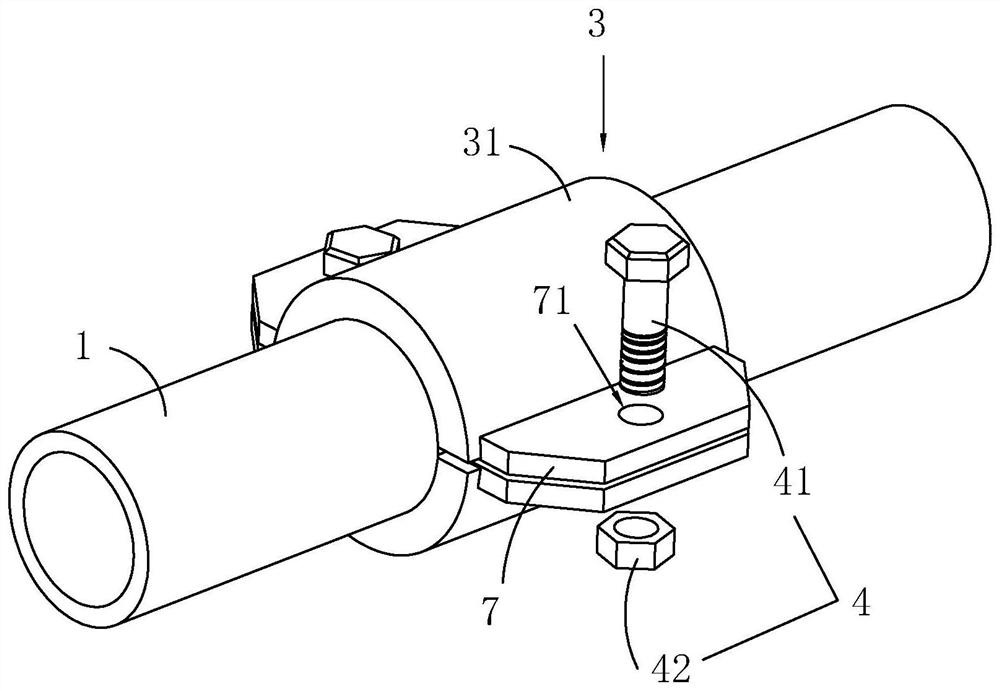

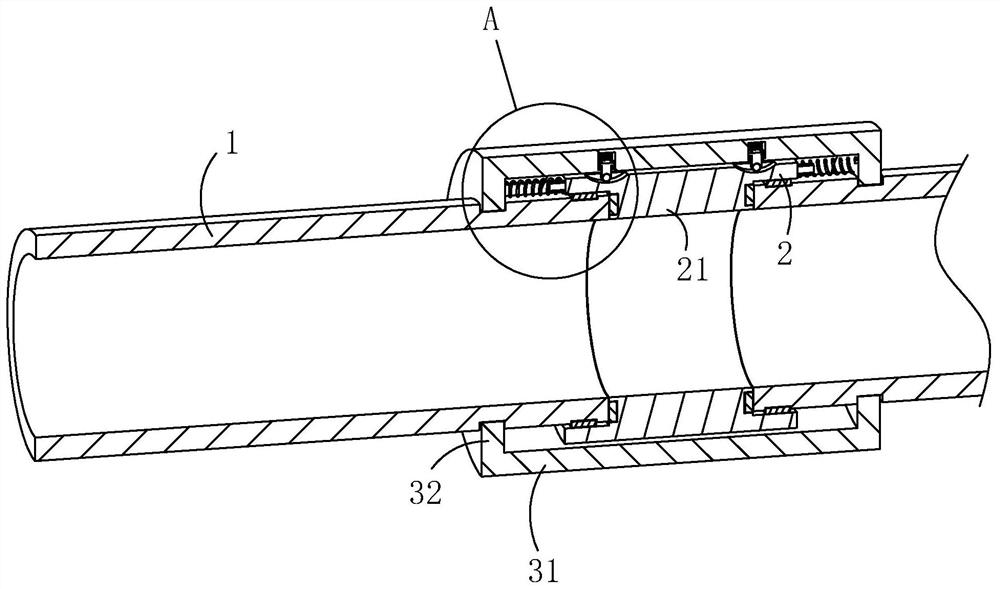

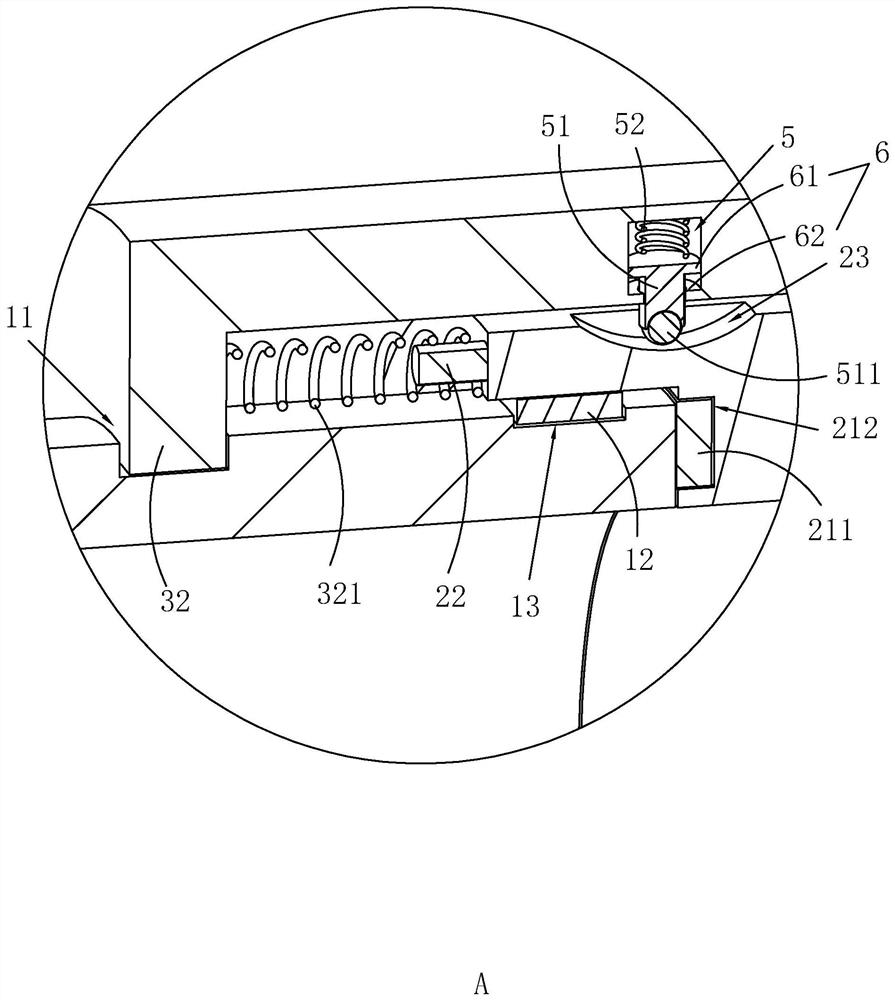

[0039] Such as figure 1 , 2 As shown, a fire-fighting pipe fitting includes a pipe body 1, a connecting pipe 2 and a fixed pipe 3, the pipe body 1 is a steel pipe, the two ends of the connecting pipe 2 are respectively sleeved on the two pipe bodies 1, and the inner wall of the connecting pipe 2 is fixed A retaining ring 21 is provided. The fixed pipe 3 includes two semi-annular half pipes 31 and a connecting assembly 4 for fixing the two half pipes 31. The fixed pipe 3 is sleeved outside the connecting pipe 2. The connecting assembly 4 includes connecting bolts 41 and nuts 42. The half pipes 31 Ear plates 7 are fixedly arranged on both sides of the ear plate 7, and a perforation 71 is provided on the ear plate 7, and the connecting bolt 41 passes through the perforation 71 of the two ear plates 7 and is threadedly connected with the nut 42.

[0040] Such as figure 2 , 3 As shown, the side wall of the fixed ring 21 close to the pipe body 1 is provided with an elastic seal...

Embodiment 2

[0050] A method for installing fire-fighting pipe fittings, comprising the following steps:

[0051] S1. Cut several sections of steel pipes with the same diameter according to the design length at the construction site;

[0052] S2. Process a concave groove 11 around the circumference on the outer wall at both ends of each section of the steel pipe close to the end face;

[0053] S3. Spray anti-rust paint on the outer surface of each section of the steel pipe after the groove 11 has been processed, and then spray the topcoat to form a multi-section fire pipe body 1 that meets the design length;

[0054] S4. Connect the two adjacent pipe bodies 1 through the connecting pipe 2, so that the end face of the pipe body 1 is pressed against the elastic sealing ring 211, and then the two half pipes 31 are fixed on the connecting pipe 2 through the connecting assembly 4, and the flange 32 Insert it into groove 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com