High-sensitive MEMS tactile sensor structure

A tactile sensor, high-sensitivity technology, applied in the direction of instruments, measuring devices, measuring force, etc., can solve the problems of poor sensor sensitivity, inapplicability, sensing signal offset, etc., to achieve high sensitivity, expand the sensing range, and transmit sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

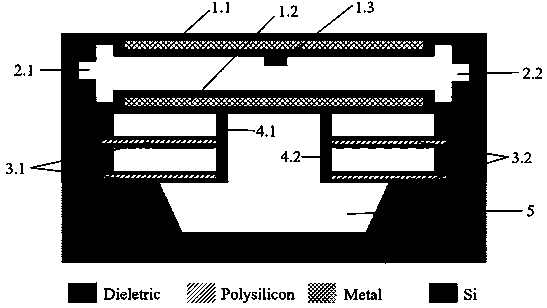

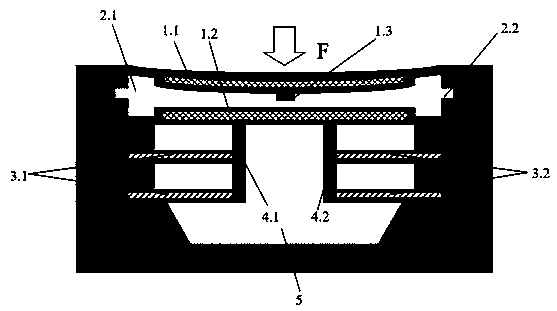

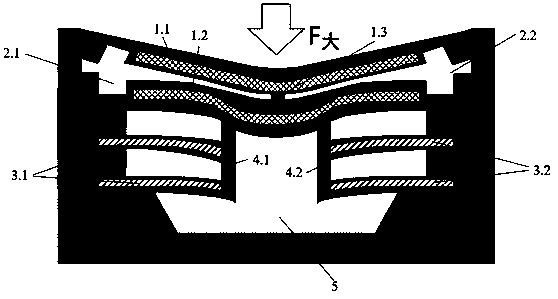

[0018] exist figure 1 , shows the structural cross-sectional schematic diagram of the tactile sensor, as shown in the figure, the sensor structure is divided into five parts:

[0019] The first part is the capacitive sensing unit, which is composed of two deformable films, and the metal is embedded in the deformable film to form the two electrodes of the capacitor, and the upper electrode 1.1 has an inner protrusion 1.3, and the position of the inner protrusion is above the supporting beam. When the capacitive sensing unit is saturated, the inner convex structure can reduce the contact area between the upper and lower electrodes, thereby increasing the pressure transmitted from the upper electrode to the lower electrode 1.2, thus increasing the deformation of the piezoresistive beam, thereby Improved sensor sensitivity.

[0020] The second part is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com