Stable clamp for testing durability of vehicle seat angle adjuster motor

A technology of car seat and recliner, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc. It can solve the problems of plastic gear damage and abnormal damage of angle-adjusting motors, etc., so as to eliminate Effects of bouncing, avoiding abnormal damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

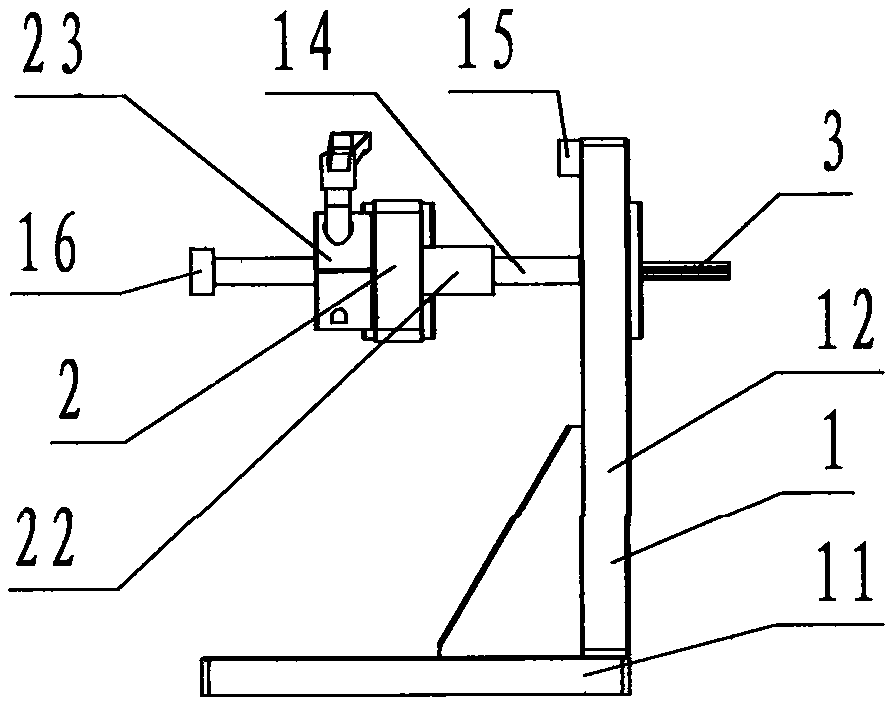

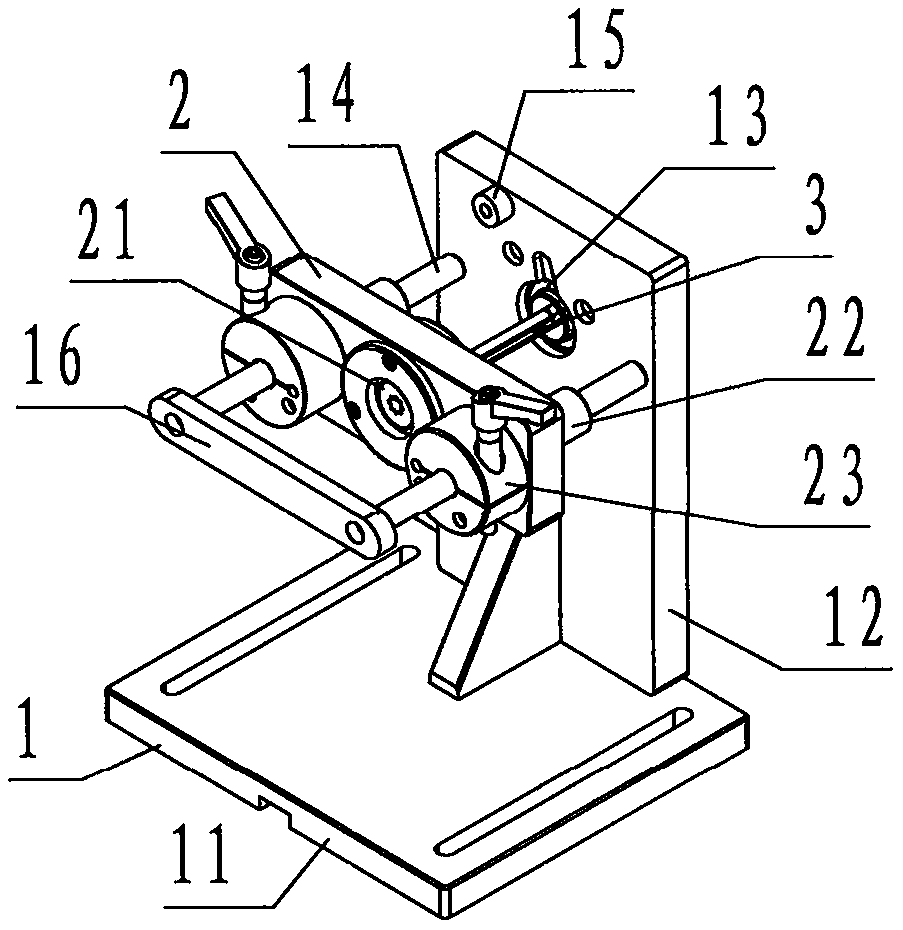

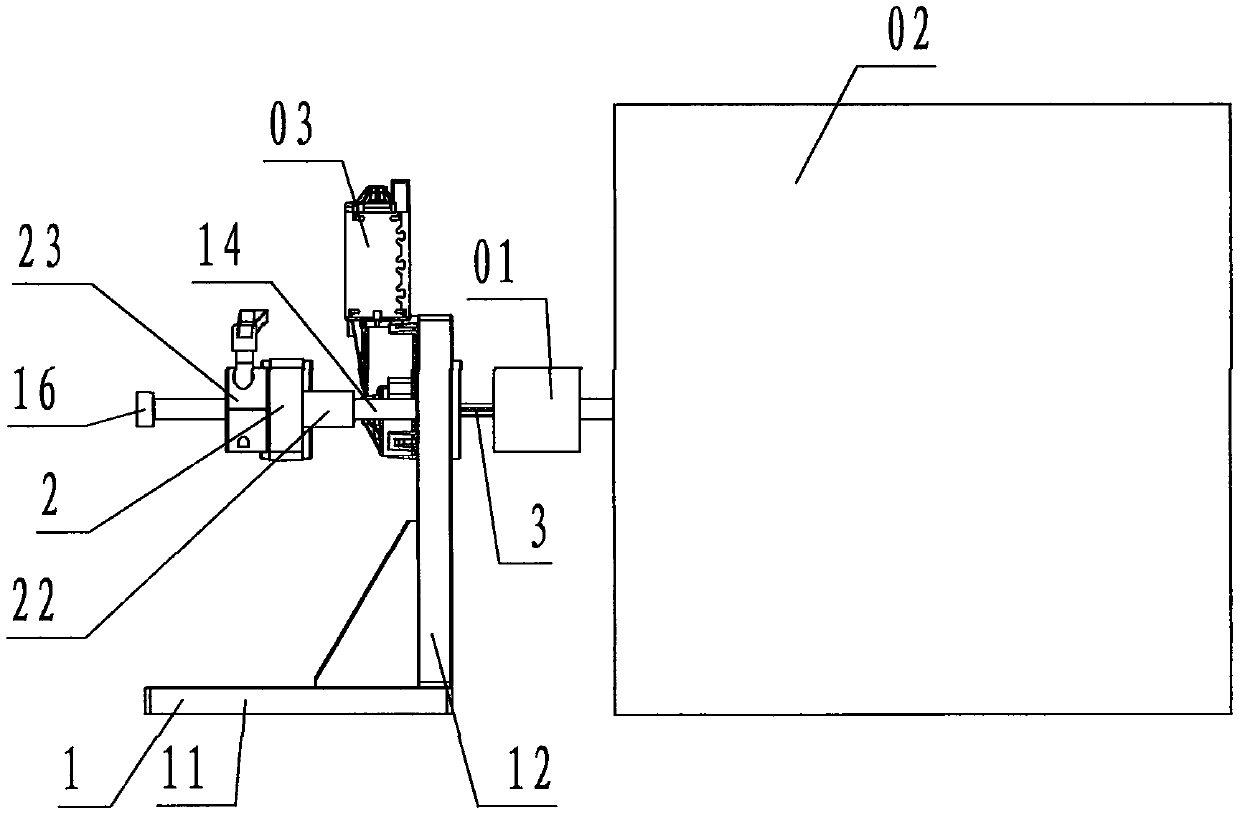

[0023] refer to Figure 1 ~ Figure 4, a stable fixture for the durability test of a car seat recliner motor according to the present invention, comprising a base 1, a moving beam 2 and a spline shaft 3, wherein: the base 1 is composed of a horizontal bottom plate 11 and a vertical The wall panel 12 is an L-shaped steel member; the wall panel 12 and the bottom plate 11 are rectangular plates, and the wall panel 12 is fixedly connected to the right side above the bottom panel 11; the front and rear sides of the upper left side of the wall panel 12 are Two cylindrical steel guide pillars 14 protruding to the left, parallel to each other, are fixed respectively, and the left ends of the two guide pillars 14 are fixedly connected with the fixed beam 16 respectively, and the fixed beam 16 is a rectangular plate-shaped Steel components; the wallboard 12 is provided with a circular through hole called A hole in the middle of the two guide posts 14, and the A hole is fixedly provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com