A tire inner quality detection device

A detection device and quality technology, which is applied in the field of tire production, can solve the problems of inconvenient inspection personnel sampling tires, etc., and achieve the effect of easy promotion and use, reasonable design and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

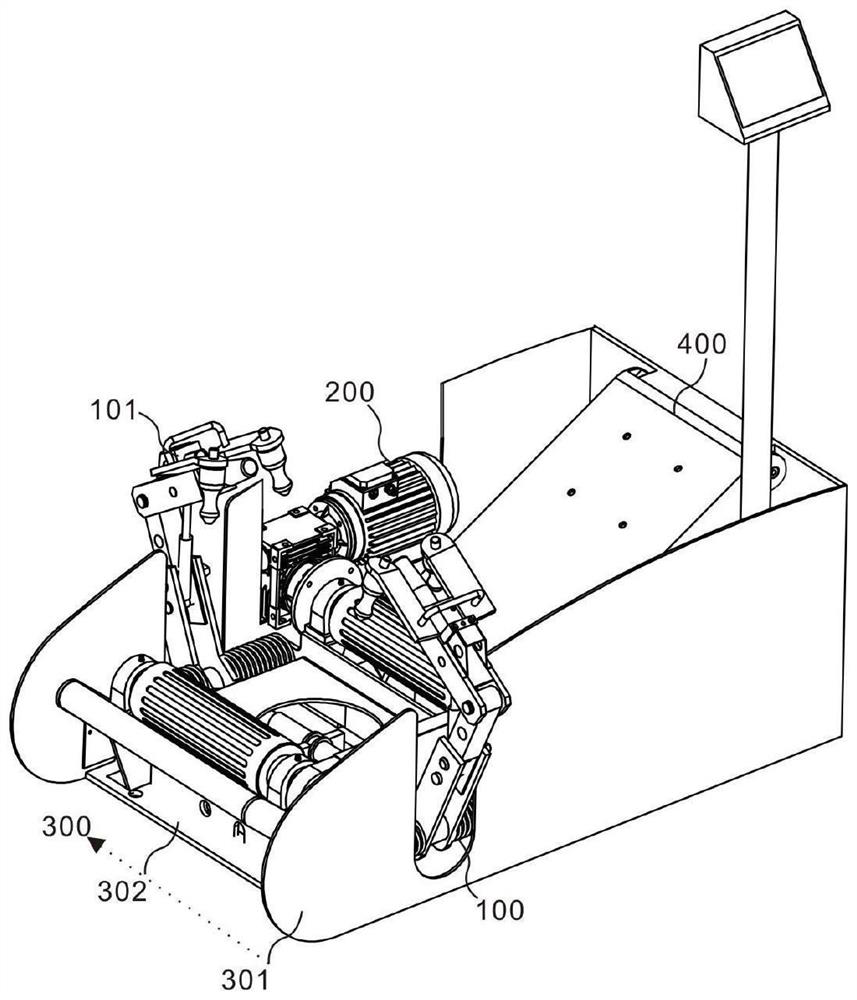

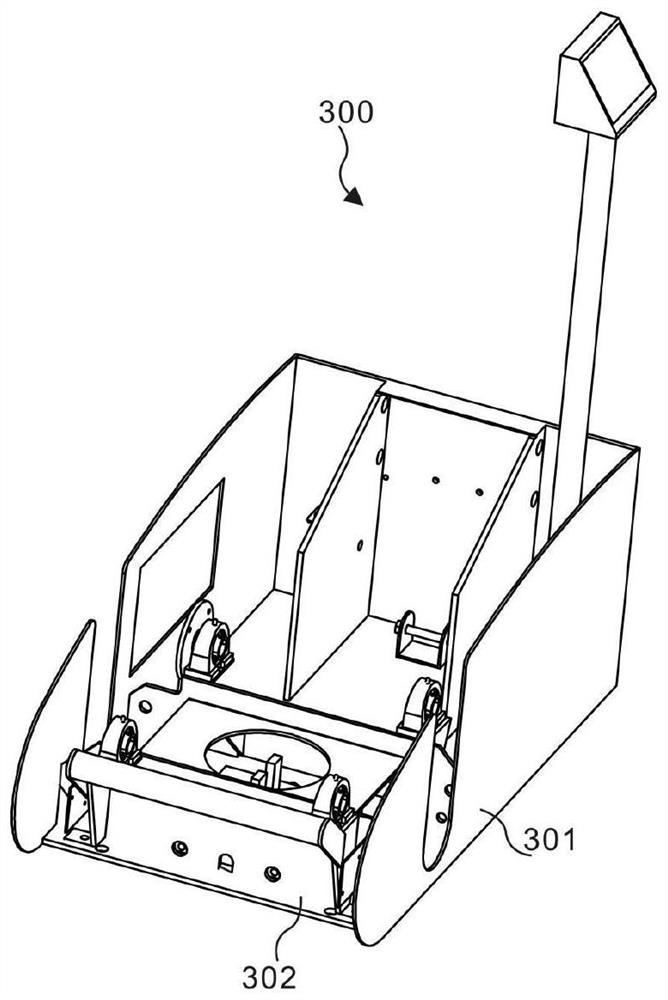

[0048] refer to Figure 1 ~ Figure 3 , which provides a schematic diagram of the overall structure of a tire inner quality detection device, such as figure 1, a tire inner quality detection device includes a pulling unit 100, including a first pulling assembly 101, a second pulling assembly 102 and a two-way hydraulic cylinder 103, and the two ends of the two-way hydraulic cylinder 103 are connected to the first pulling assembly 101 and the two-way hydraulic cylinder 103 respectively. The second pulling assembly 102 is connected, and the first pulling assembly 101 and the second pulling assembly 102 are arranged symmetrically; the driving rotation unit 200 includes a rolling driving assembly 201 and a rolling assembly 202 connected with the rolling driving assembly 201, and the rolling assembly 202 Arranged in parallel with the two-way hydraulic cylinder 103; the bearing unit 300 includes an outer shell 301 and a supporting shell 302, the pulling unit 100 and the rolling assem...

Embodiment 2

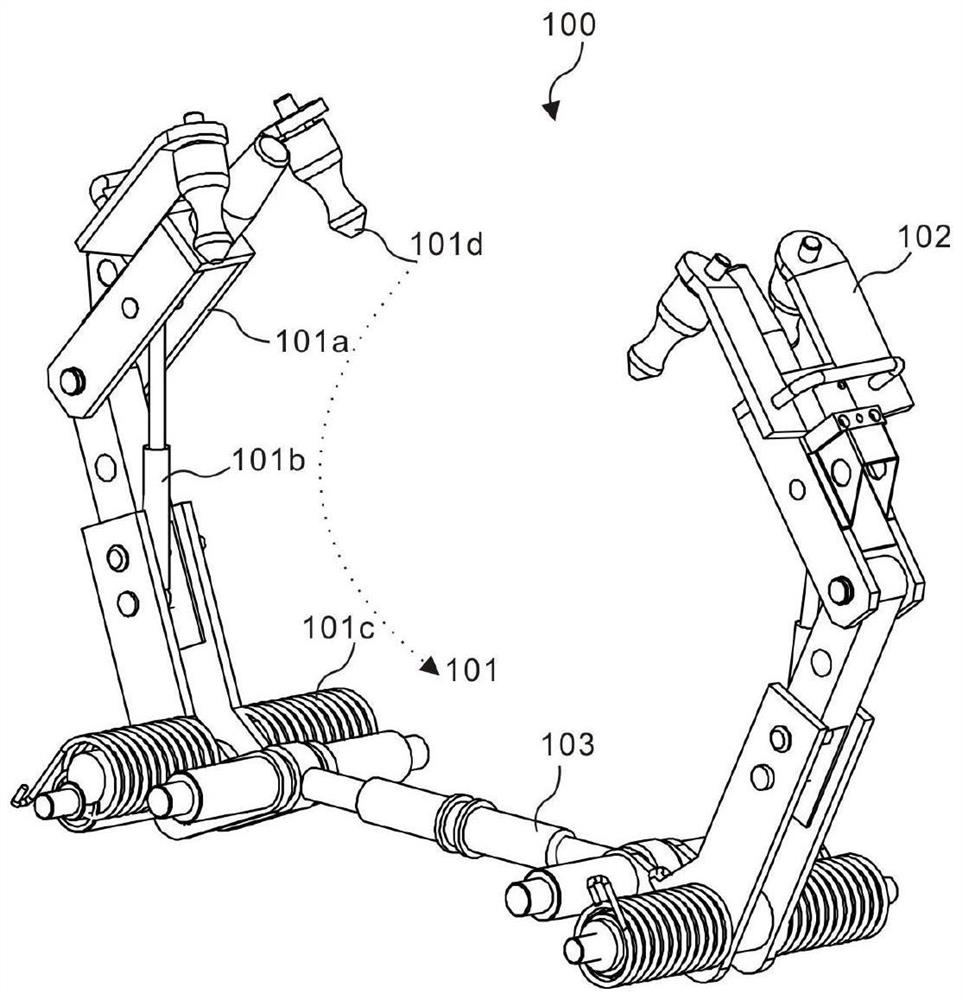

[0055] refer to Figure 6 , This embodiment is different from the first embodiment in that the structure of the first pulling assembly 101 is the same as that of the second pulling assembly 102, and the first pulling assembly 101 includes a linkage 101a, a linkage driving element 101b, a support The part 101c and the claw 101d can pull out the inner side of the tire through the mutual cooperation between the linkage 101a, the linkage drive 101b, the support 101c and the claw 101d, which is convenient for inspection personnel to detect, saving time and effort. Specifically, the structure of the first pull assembly 101 is the same as that of the second pull assembly 102, the first pull assembly 101 includes a linkage 101a, a linkage drive 101b, a support 101c and a claw 101d, and the linkage drive 101b The two ends of the link 101a are respectively connected to the first connecting arm 101a-1 and the second connecting arm 101a-2, and the pulling claw 101d is arranged on the seco...

Embodiment 3

[0060] refer to Figure 7 and 8 This embodiment is different from the above embodiments in that: the lifting unit 400 includes a lifting linkage assembly 401 and a lifting driving assembly 402, and the lifting linkage assembly 401 and the lifting driving assembly 402 are arranged to cooperate with each other to drive the supporting shell 302 to lift , so that the unplugging unit 100 can be realized, and the lifting and lowering of the driving rotation unit 200 can be realized, thereby providing conditions for adapting to testing personnel of different heights, and greatly increasing the practical performance of testing. Specifically, the lifting unit 400 includes a lifting linkage assembly 401 and a lifting drive assembly 402. The ends are respectively connected to the support plate 302e and the second bottom plate 301b of the outer shell 301.

[0061] Further, the lifting linkage assembly 401 includes a linkage cover 401a, a first shaft group 401b, a second shaft group 401c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com