High-temperature in-situ loading stress measuring device for neutron diffraction

A technology of stress measurement and in-situ addition, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem of inaccurate stress and strain measurement results, inconvenient dynamic observation, and no consideration of creep effects etc. to achieve the effects of optimizing creep test measurement, improving angle range, and simplifying overall size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

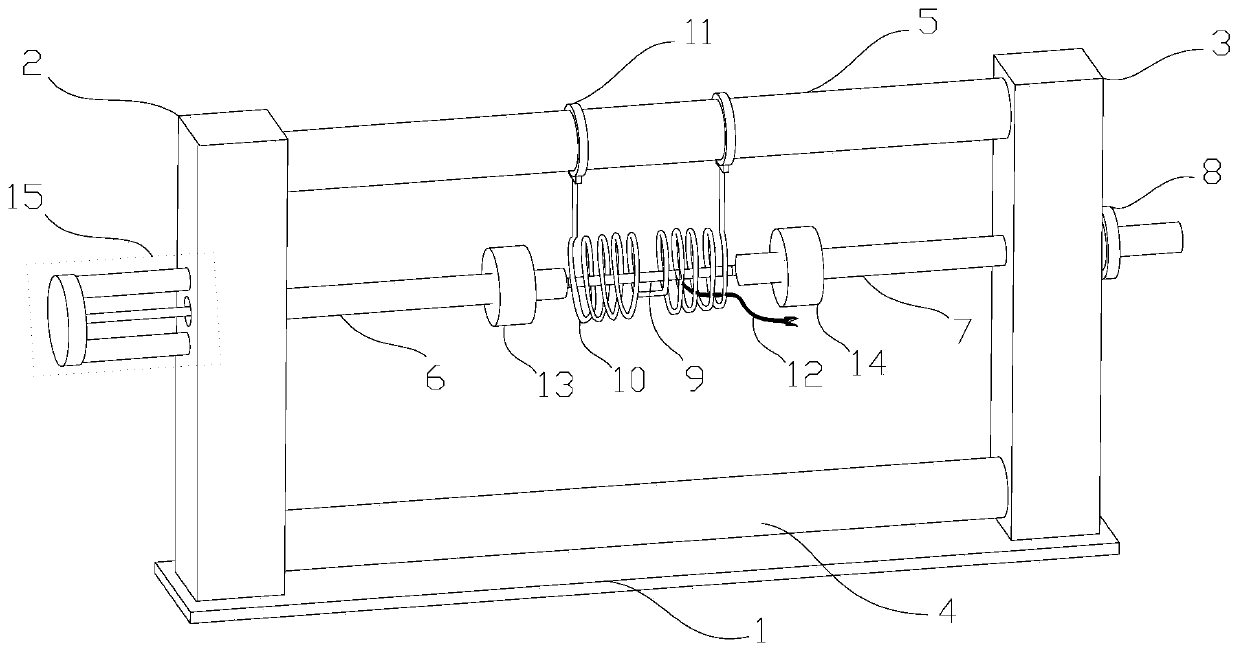

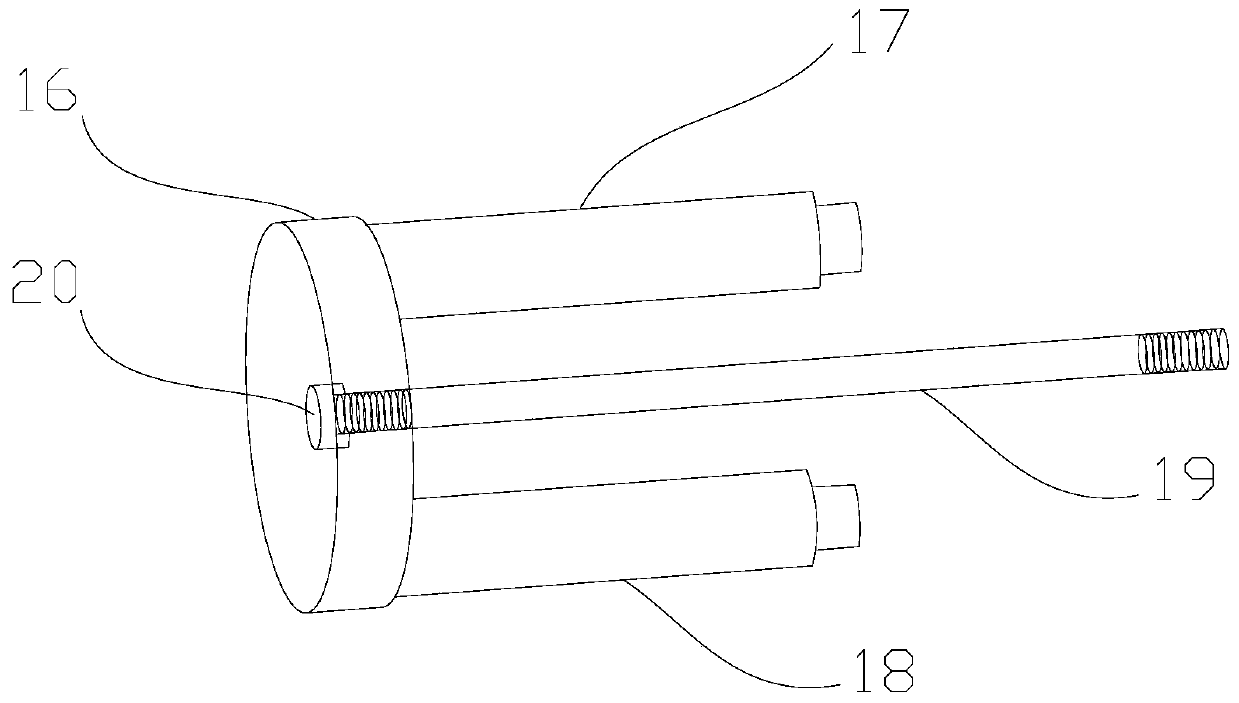

[0028] Such as figure 1 and figure 2 As shown, this embodiment discloses a high-temperature in-situ loading stress measurement device for neutron diffraction.

[0029] The device is mainly composed of the following four parts, a support frame, a mechanical stretching component, a heating component and a sample connecting rod component 15 .

[0030] The support frame includes a base 1, a left column 2, a right column 3 and a connecting shaft, wherein the connecting shaft in this embodiment includes an upper connecting shaft 5 and a lower connecting shaft 4, and all components are preferably made of high-strength alloy materials and passed through Welded fixed connections to ensure overall stability of the unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com